How Much Does an Overhead Bridge Crane Cost?

Overhead cranes are lifting equipment which can increase efficiency, productivity, and worker safety in your production process. When budgeting for a bridge crane for your business, you may wonder what costs lay ahead of you. “What is an overhead bridge crane price” That is frequently asked questions by clients. However, if you're ready to install an overhead bridge crane in your workshop, then you may have already assessed the return on investment for such a bridge crane purchase. Generally, overhead crane price is affected by various factors, such as overhead crane types, crane span length, overhead crane lifting capacity, crane duty cycle, overhead crane application or operation environment, building structural conditions, overhead crane manufacturers and demand from terminal consumers or crane operators. All have an impact on overhead crane prices.

Various factors influence overhead crane costs, including:

Types of Overhead Bridge Crane

The specific crane model and its load-bearing capacity significantly impact price. There are several different types of cranes, each suited to a particular application. For example, suppose a gantry or free-standing workstation crane works for your needs. In that case, those simpler and relatively more compact lifting systems may cost substantially less than a double girder overhead bridge crane used for moving significantly larger loads farther. This would be due to the increased complexity of the engineering for a bridge crane, more materials to build it, and the additional components.

Lifting Capacity

The maximum load your crane can lift can make a difference in its total cost. Cranes built to withstand larger capacity loads will require the energy, engineering, materials and components to support excessive weights. The max loading capacity of an overhead bridge crane can up to 500 ton. At the same time, lighter lifts can be accomplished using much less from smaller and less expensive types of cranes such as workstation cranes. When all other specifications and factors are same, the cost of a 10 ton overhead crane is obviously lower than a 20 ton overhead bridge crane cost.

Span Length

The span of a bridge crane is the length between its runway tracks, in other words, the length of the crane. It range from 6m up to 30m. The longer the crane, the greater the need for additional engineering requirements and the more steel used to build bigger crane girders. Longer span bridge cranes cost more, as they require bigger structural components, support systems, and engineering designs.

Runway Length

Do you plan on saving money by installing a new bridge crane onto an existing runway in your workspace? If so, you must be sure that the old structure can support the weight and loading of the new crane, and if not, modifications may be needed, which could incur more expense. The runway length is the most significant factor in the overall cost of the runway. The overhead crane's price may be influenced by the rail length.

Duty Cycle

Frequency of use and the percentage of weight lifted compared to the rated capacity could have the biggest affects on cost. Clients are supposed to pay more for larger, heavy-duty process bridge cranes that require robust components, use of more raw materials to build and special engineering to withstand incredibly working conditions.

Environmental Conditions

Factors like indoor vs. outdoor use and harsh working conditions play a role in determining the right crane and its cost. For example, the overhead crane may work in high-hazard environments containing flammable, toxic vapors or gasses, chemicals or fumes, steam, combustible metal, carbon or grain dust. There may be concentrations of hazardous substances in the air of your crane's working environment or materials that are handled or processed in your facility. The Stainless Steel Overhead Bridge Crane or Explosion Proof Overhead Bridge Crane with Spark Resistance components will be used to prevent fires or explosions on the worksite.

The Cost of Transporting an Overhead Bridge Crane

The cost of transportation may be very high for overhead bridge crane exportation. If your overhead crane is delivered in containers by sea shipment, transportation fees include inland freight, sea freight, packing reinforcement fee, cargo costs, port taxes, and shipping insurance. Furthermore, the cost of customs clearance should be factored in. The cost of an SGS / BV inspection will be added to the total when a third-party inspection is required.

Overhead Bridge Crane Installation Cost and Maintenance Cost

The installation complexity of the crane can drive up overall expenses in your facility. Installing an overhead crane needs skillful professionals, following manufacturer instructions. Regular maintenance is imperative to keep it running smoothly. It includes inspections, lubrication, repairs, and replacing worn-out parts. Training personnel is a must for safety compliance.

Automation System and Safety

Integrating automation and safety features into crane operations increases initial costs but offers long-term savings and efficiency. And it is necessary to think about the control mode of the automated bridge crane. Will a wireless radio remote control, a pendant control, or a crane cab control be used to operate the overhead crane?

Average Cost Ranges for Different Types of Overhead Cranes

When planning your overhead crane investment, it’s essential to have a clear picture of the basic types of overhead bridge cranes.

Single Girder Bridge Crane Cost: $4,000.00-$8,000.00 A cost-effective solution for light to medium lifting needs.

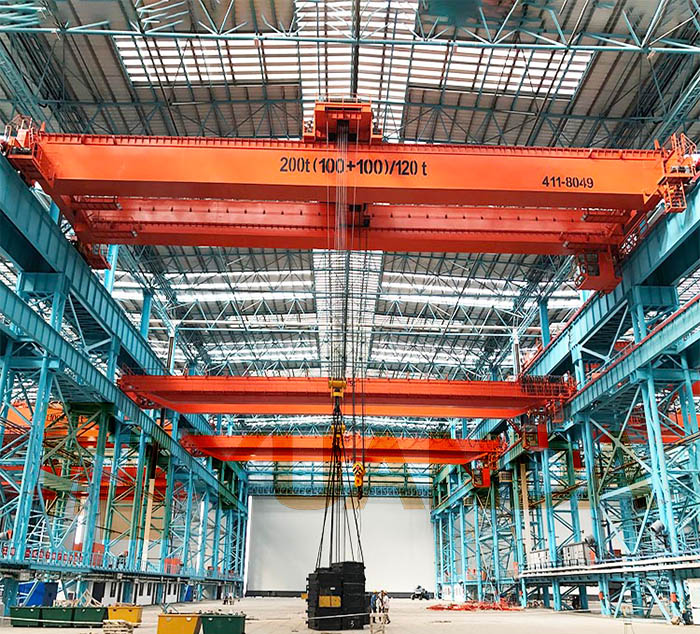

Double Girder Bridge Crane Cost: $7,000.00-$15,000.00 Suitable for heavier loads and longer spans, providing higher lifting capacities. For example, 25 ton overhead bridge crane, 30 ton overhead bridge crane and 40 ton overhead bridge crane.

EOT Overhead Crane Cost: $9,000.00-$150,000.00 EOT electric overhead traveling cranes are crucial for seamless material movement across various industrial scenarios. Hot series are 50 ton overhead bridge crane and 60 ton overhead bridge crane.

Top Running Overhead Bridge Crane Cost: $5,000.00-$150,000.00 Top-running overhead cranes typically are larger with greater lifting capacities, at 100 tons 200tons or more. They're also easier to install and service.

Under Running Overhead Bridge Crane Cost: $3,000.00-$9,000.00 Also known as underslung bridge crane or underhung bridge crane, the suspended overhead bridge crane is typically for capacities under 10 tons and are most commonly ceiling supported for maximum floor space utilization.

Monorail Crane System Cost: $3,000.00-$6,000.00 Efficient for linear movement, supporting process workflows.

Freestanding Workstation Overhead Bridge Crane Cost: $8,000.00-$15,000.00 Optimized for ergonomic operation and safety in confined areas.

Engineered Gantry Crane Cost: $5,000.00-$20,000.00 Designed for specific applications, offering mobility and heavy-duty lifting.

Jib Crane Cost: $2,000.00-$8,000.00 Ideal for localized lifting tasks, offering flexibility in small spaces.

Some overhead bridge cranes have unique features. For example: Magnetic overhead bridge cranes have magnets that lift ferrous materials, meaning they don't need extra lifting devices. Grab bucket overhead bridge cranes usually employed to handle bulk materials such as coal, stone, sand, metal scrap, garbage, etc. During the process of smelting liquid metal in steel mill, metallurgic overhead cranes or foundry overhead bridge cranes are used specially for transporting and handling hot metal in ladle.

When it comes to the cost of an overhead crane, there are many things to take into account. The size, capacity, optional features, and customizations will all factor in. Manufacturer and quality make a difference too. Selecting the right overhead crane is a strategic decision that affects not just your budget but also operational effectiveness and safety. For further guidance, you can find more details on the product pages or contact us today.