Jib Crane

Jib Crane For Sale

Industrial jib crane is a lifting device with an arm or boom that extends off the main body of the crane to provide additional extension and has a lattice design to reduce the weight added to a load.

Electric hoist jib crane can improve production, assist in efficiency, and improve workplace safety by performing heavy lifting jobs quickly without the need for manual labor. They are made of heavy duty steel materials that can withstand the high work grade under constant use.

The simple design of swing arm jib crane gives them the capability of being installed in any type of work space. They are versatile and adaptable pieces of equipment that can be configured to suit the needs of small work spaces to save workers from lifting heavy and bulky materials.

Harga hoist jib crane 5 ton have a basic simple design and construction consisting of a beam and boom with various components added to enhance and simplify the crane's use. Each swivel jib crane is designed with some having trolleys and electrical controls while others are operated by wire ropes, levers, and chains.

Manufactured by 304 or 316, the stainless steel jib cranes with electric chain hoist are corrosion-resistant and ideal for food, pharmaceutical, medical, chemical industries and clean room, laboratory application. Lifting capacity 50kg, 80kg, 100kg, 250kg, 500kg and 1 ton.

Lightweight 500kg freestanding jib crane with electric hoist can be ground floor mounted, pillar mounted, column mounted, wall mounted or portable type. Either on foundation or foundationless, 1/2 ton jib crane is used for workshop, warehouse and workstation. Get 1000lbs jib crane price from China supplier now.

Heavy duty 10 ton floor mounted jib crane with electric hoist, is designed as freestanding, pillar mounted, or column mounted type. With ground foundation, it is widely used for workshop, warehouse, indoor and outdoor for lifting. Consult 10 ton jib crane price with China supplier now.

Heavy duty 5 ton freestanding jib crane with electric hoist, is designed as ground floor mounted, pillar mounted, column mounted or wall type. Fixed on concrete foundation, it is widely used for workshop, warehouse, workstation, indoor and outdoor for lifting. Get 5 ton jib crane price from China supplier now.

Heavy duty 3 ton freestanding electric hoist lift jib crane can be ground floor mounted, pillar mounted, column mounted, wall mounted and portable type. With ground foundation, it is widely used for workshop, warehouse and workstation. Get 3 ton jib crane price from China supplier now.

Mounted to floor, wall or portable counterbalance base plate, the lightweight vacuum lifter jib crane is a swing jib crane with integrated pneumatic vacuum lifter. This suction cup vacuum handling system is used to lift marble, glass, granite, plywood, wood panel, metal sheet, slab, carton, drum, barrel, bag, etc.

1 Ton Mobile Portable Jib Crane on Wheels, also known as movable jib crane, is a cantilever jib cranes movable with counter weight balance base or motorized wheels, allow the operator to easily transport the crane using a forklift. Capacity 500kg 1ton 2ton 3ton 5ton.

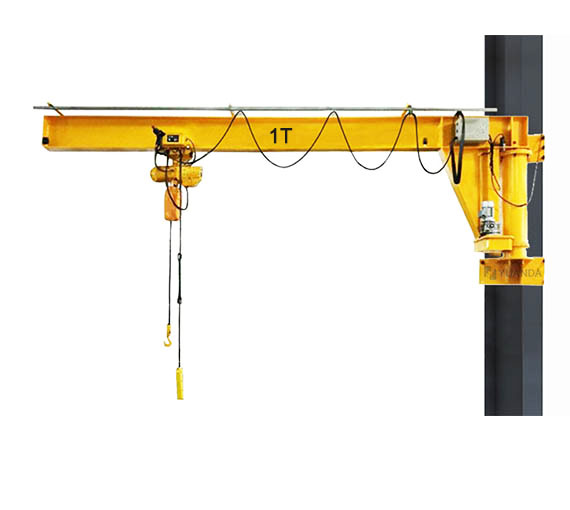

Designed to be fixed on a wall, post or column, a cantilever wall mounted jib crane with electric hoist is the cost-effective solution for industrial use in workshops. The loading capacities 100 lbs, 500kg, 1ton, 2 ton, 3 ton to 5 tons. Contact us for a price quote.

We offer wall mounted, column mounted, foundation floor mounted or freestanding articulated jib crane. It is also known as knuckle boom jib crane, with lift capacity ranging from 100 to 2,000 pounds. Contact us now for a price quote.

We are China manufacturer for freestanding jib crane and floor mounted jib crane, with lifting capacity 500kg, 1ton, 2ton, 3ton, 5ton to 10tons. Either heavy or light-duty, the jib crane with electric hoist is the optimal solution for your workshop. Contact us now for a price quote.

Heavy duty 2 ton freestanding jib crane with electric hoist is designed as floor mounted, pillar mounted, column mounted, wall mounted or portable type. With ground foundation, it is widely used for workshop, warehouse, workstation and outdoor for lifting. Get 2 ton jib crane price from China supplier now.

Lightweight 1 ton freestanding jib crane with electric hoist, can be made as ground floor mounted, pillar mounted, column mounted, wall mounted or portable type. Either with foundation or foundationless, it is used for workshop, warehouse, workstation, indoor and outdoor for lifting. Get 1 ton jib crane price from China supplier now.

Jib Crane

Features of Cantilever Swing Arm Jib Crane

- Model number: BZ, BZD, BXD, BD

- Lift capacity: 25kg 50kg 100kg 125kg 150kg 200kg 250kg 300kg 350kg 500kg 1000kg 1500kg 2000kg 2500kg 3000kg 5000kg

- Heavy loading weight: 500pound, 1000lbs, 2000lbs,2500lbs, 3000lbs,5000lbs,6000lbs,8000 pounds

- SWL/WLL(Loading capacity): 0.25t 0.5t 1t 2t 3t 5t 7.5t 8t 10t 12t 15t 16t 20t

- Rotation: 90° 180° 270° 360° degree rotating Jib Cranes

- Span(boom arm length): 10ft. 15ft. 20ft. 25ft. 30ft.

- Height Under Boom (HUB):5ft 7ft 10ft 12ft. 24ft. 2 3 4 5 6 7 8 9 10 m meters

- Overall Height (Crane Only): 5ft 7ft 8ft 10ft 13ft 15ft 2m 3m 4m 5m 6m 8m

- Hoist & Trolley Allowance: 100lbs 200lbs 300 lbs.

- Anchor Bolt Load: 4.07 Kips/Bolt

- Base plate Thickness at Anchor Bolt: 1 1/4 in.

- Coverage: 360° Circular Rotation

- Crane color: Powder-coated finish, painted Safety Yellow RAL1028. Special epoxy primer available for outdoor use.

- Control method: Ground control, wire button control, pendant control, wireless radio remote control jib crane

- Lifting mechanism of jib crane: With electric chain hoist, electric wire rope hoist, lever or ratchet hoist, chain block, manual chain hoist jib crane with winch.

- Lifting weight: 0.5ton 1/2 ton 1 ton 2 ton 3 ton 5 ton 10 ton 15 ton 20 ton(tonne/tn/metric ton/MT)

- Standards: FEM, ASME, DIN 15018 standards, all steel frame structure. Supplied with EC Declaration of Conformity

- Overbraced Tie Rod or Under-Braced I Beam Type

- Independent head assembly installs separately for ease of installation.

- In-head totally enclosed, bottom entry collector assembly allows the option of easily adding power to the hoist for 360° rotation at the time of or after purchase.

- Festoon Options includes: Entry Collector or Air Swivel, Cable or Air Hose, Tagline Kit, and Wire Rope Trolleys.

- Special foundations may be required; crane drawing will have foundation requirements.

- All holes in steel with bearing loads are either punched or drilled. Flame cut holes are not permitted in these applications.

- Applicable industries: Light weight jib crane for workshops, building material shops, machinery repair shops, manufacturing plant, food & beverage factory, warehouse, workshop, construction works, energy & mining, indoor and outdoor.

- Jib crane manufacturer: Jib crane China supplier

- Lifting speed: Dual speed or variable speed (custom)

- Power supply: AC-3Phase-220/380/400/415/440V-50/60Hz

- Work duty: A3-A5 / Light duty / Heavy duty

- I beam construction or Hollow section C

rail channel profile or Lightweight aluminum enclosed track

design, aluminum profile rails for jib arm/boom

All China Yuanda Jib Cranes have a design

factor of 15% of the allowable capacity for hoist weight and 25% of the

allowable capacity for impact.

Different Types

of Jib Cranes

As with all cranes, stationary jib crane is overhead lifting equipment that is attached to a horizontal beam, the ceiling, a column, or a wall. According to the installation methods, the fixed jib crane can be made as ground floor mounted jib crane, pillar mounted jib crane, wall mounted jib crane. Regarding the foundation of the jib crane, there are freestanding jib crane, foundation jib crane, foundationless jib crane, base plate mounted jib crane. As per the lifting boom types, there are I beam jib crane, light duty KBK rail jib crane, aluminum rail jib crane, light and compact jib crane with folding arm. Regarding the mounting types, there are column mounted jib crane, pole mounted jib crane and post mounted jib crane. Adapted to diverse applications, it can be sorted as jib crane for outdoor, marble jib crane, glass jib crane, plywood sheet slab jib crane, clean room jib crane, air pneumatic jib crane vacuum lifter. What’s more, it is known as remote control jib crane, electric jib crane, pendant control jib crane, manual jib crane sorted by different control mode and power supply. And there are some special types of jib crane such as telescopic jib crane, hot-dip galvanized jib crane, stainless steel jib crane, explosion proof jib crane and adjustable height jib crane for special applications.

Free Standing Jib Cranes

Freestanding jib cranes are the most common

type of jib crane base plate 1 ton and can be installed

for indoor or outdoor applications. Also known as slewing arm jib cranes or

cantilever jib cranes, free-standing jib crane are traditionally bolted to the

floor, using chemical anchors. The fixed floor mounted jib cranes are available

in both under-braced and over-braced profiles with arms reaching up to 9m in

length and working load limits from 500kg up to 1 tonne. There are three designs of freestanding jib cranes, which are base

plate mounted jib crane, foundation mounted jib crane, and sleeve insert

mounted.

Light Duty Foundationless Jib Cranes

Foundationless jib cranes are the fixed

column rotate jib crane that does not require a pre-poured foundation. It can

be bolted to an existing concrete surface and are great in open areas where

they can serve several work stations.

Manual Jib Crane

Also known as manual slewing jib crane or

hand operated jib crane, this light weight manually rotated jib cranes are

designed for the material handling inside a work plant, in a square or to serve

operative purposes. The manual rotating jib cranes are available for lifting

capacities from 50kg to 2000 kg and jib boom length from 5m to 8 m. Jibs can be

enclosed C rail channel profile or I beam.

Articulating Jib Cranes

Also referred to as fold arm jib crane, an

articulating jib crane has a swivel arm and a boom. They rotate easily and have

consistent responsiveness for positioning loads and can be positioned to reach

loads around corners and obstructions. Articulated jib cranes can be wall

mounted, floor mounted, ceiling mounted, or mounted on a bridge system.

The rotation of the two arms can be locked

and come in three different arm lengths. The primary arm has a 200° swivel, while the outer arm can swivel

360°, which allows it to

reach into machinery and containers. The many configurations of articulating

jib cranes make it possible to have precise load positioning and spotting loads

around obstructions.

Wall Mounted Jib Cranes

Wall mounted jib cranes, also known as wall

mounted boom lift or wall cantilever jib cranes, are space saving types of jib

cranes on walls, that do not require floor or foundation space. The wall

bracket jib crane serves as a supplement to a monorail or overhead bridge crane

and can be installed close to the underside of the building structure allowing

for maximum clearance under and above the boom. It can be made as Over-Braced

or Under-Braced wall mounted jib crane.

When wall type jib cranes are not in use,

they fold away along the wall to prevent obstructing or interfering with

production. The fixed wall mounted jib cranes have spans ranging from 8 feet up

to 30 feet with weight capacities up to 3 tons. The two designs of cantilever

slewing jib cranes are cantilever wall jib crane and top braced tie rod support

wall mounted jib cranes.

Mast Jib Cranes

Mast type jib cranes are floor supported

and top stabilized with the top being supported by the beams of the building.

Unlike foundation supported and base plate supported jib cranes, mast jib

cranes take up little floor space and do not require holes in the foundation.

The fact that the structure of the building does not have to be altered to

accommodate fixed floor jib crane makes them a very economical lifting method,

much like a tie rod supported jib crane.

Portable Jib Cranes

Portable jib cranes are installed on a

mobile base that can be motorized wheeled or fork lifted depending on their

design and have a capacity of less than a 1/2 ton. The traveling jib crane with

wheels and tyres is also referred as wheeled jib crane, moveable(movable) jib

crane or cantilever mobile jib crane. The design of small portable jib cranes

means that one person can move large amounts of materials without the need for

other resources.

The key to electric mini jib crane design

is to ensure that the apparatus is stable without having to be secured. Their

core is very light for easy mobility such that they can be positioned close to

a work area.

Hydraulic Jib Crane

A hydraulic jib crane is another version of

a mini swing jib crane with the added feature of a hydraulic cylinder to raise

and lower the arm of the crane. The lifting system of a hydraulic jib crane

uses a hydraulic cylinder that is attached to the boom of the crane to lift and

lower loads. The hydraulic mechanism can be powered by a battery or be a hand

pump type depending on the design of the crane.

The lifting mechanism of a hydraulic jib

crane has a capacity of one ton when the boom is retracted and 500 pounds when

the boom is extended.

Wall Traveling Jib Crane

A wall travelling jib crane travels along

rails that are mounted on the walls of a building or some form of supporting

structure. They are designed to use the full space of a building for moving,

lifting, and transporting loads. Wall traveling cranes are designed for lateral

movement of loads using the vertical lifting mechanism of the crane.

Workstation Jib Crane

Workstation jib cranes, also known as

workshop jib crane, are a means for improving productivity while ensuring the

safety of workers. Column slewing jib crane makes it easy for workers to

manipulate and position a work piece as well as move a work piece onto other

applications. Workstation jib cranes come in all of the available mounting

configurations to specifically meet the needs of an application.

The majority of workshop jib cranes are

freestanding with a standard height of 12 feet and a 360° rotation. Mounting plates vary depending

on the capacity of the crane with small jib cranes using square mounting plates

with gussets while large capacity ones have hexagonal mounting plates and

gussets.

Vacuum Lifter Jib Crane

Also called as pneumatic jib crane or suction cup jib crane, it is the jib crane with vacuum lifter for granite, slab, glass, carton, box, stone, marble, metal sheet, etc. The flexible lightweight articulated jib crane is with an integrated vacuum lifter, pneumatic balancer or tool balancer for quick and easy lifting.

Technical Parameter of Jib Crane for Sale

*Motorized jib crane specifications may be

subject to change without notice

Heavy Duty Jib Crane Accessories, Components

and Jib Crane Parts

There is a long list of factors that go into the design and construction of pedestal slewing jib cranes, with each one being an improvement to assist in productivity and the safety of workers. Precision tapered roller bearings in top pivot and trunnion assemblies provide smooth operation and long life. Full supporting triangular base plate gussets are used instead of struts to minimize crane deflection and make positioning loads easier. From its basic structure, ergonomical jib crane has been engineered, crafted, and manipulated to fit a wide range of lifting applications.

Mast Components

The mast is the vertical beam upon which the components of a 2T jib crane installation. They are found in the majority of 3 ton jib crane except for wall mounted, wall traveling, column mounted, and ceiling mounted ones. Jib cranes with a mast are typically cantilever jib cranes with a full 360° rotation. The main variation of the jib crane for workshop is how they are attached to the floor or walls, with mountings being foundational, sleeve, or plate bolted.

Jib Crane Boom

The boom jib crane is the major weight bearing portion of any type of custom jib crane. It extends out from the mast, wall, ceiling, or a column and is a horizontal beam that is perpendicular to the floor. Contained on the boom is the hoist that is used to lift and move the load. For some versions of jib cranes, the boom is the support along which a trolley moves as it transports a load.

Jib Crane Hoist

The electric hoist is the mechanism that is attached to the boom and does the lifting for a workshop ground stationary swing jib crane. Some of the types of industrial hoists are electric chain hoist, intelligent lift assist devices, smart balance hoist(zero gravity hoist with floating mode), electric wire rope hoist, electric winch, manual chain hoist, manual block, rope balancers, vacuum tube lifters, grippers, air pneumatic vacuum lifters with suction cups, and tool balancers. Hoist brand: Our own brand YUANDA or international top brand such as: Demag, Abus, Kito, KONE, YALE, PLANET, Gorbel, etc. Another distinguishing factor for hoists is their power source, which can be manual, electrical, battery powered or pneumatic.

Other spare parts include jib crane motor, jib crane bearing, jib crane vacuum lifter, etc. Jib crane with electric hoist allows operators to position loads precisely, effortlessly, and efficiently.

Uses for Jib Cranes

The purpose of 1 ton jib crane is to reduce and simplify repetitive lifting tasks and limit the amount of manual labor. The different styles of fixed column type rotary jib crane make it possible to adapt them to fit the needs of any type of lifting or load bearing application. Jib cranes are one of the most versatile high capacity low cost tools or lifting equipment available.

The applications and uses for 2 ton jib crane are endless due to their ability to lift awkward heavy loads and place them accurately. They can be found in auto shops for moving engines and on production lines for supplying large parts. Manufacturers are continually designing and perfecting uses for these flexible and reliable tools.

Jib Crane in Manufacturing

Pole mounted swing jib crane is a major factor in assembly processes. It is set up at workstations to assist workers with assembly operations and is positioned close to production lines for material handling and transport. Pillar type workshop jib crane with electric chain hoist has been a major benefit in reducing the strain on employees and improving productivity. The convenience of jib crane operation makes it possible to have supplies readily available such that work can proceed faster and more efficiently.

Marine Jib crane for Shipping

Marine Jib Crane in several fashions have always been a part of shipping for offshore loading and unloading of ships and trucks. In many cases, the types of cranes are very large and robust with several tons of capacity. In the midst of the massive cranes are jib cranes that can efficiently load and unload boats as well as move materials off the dock or load them onto trucks. Moreover, there are boat lifting jib crane, which is installed on marina, quay or dock to lift the boat out of water.

Jib Crane for Construction Industry

The construction industry is constantly being confronted by the challenges of moving heavy materials into hard to reach locations. These conditions can involve underground foundations and multi-floor buildings. The jib crane for outdoor is possible to shift and place stacks of materials into these hard to reach locations saving manual labor and time as well as enhancing productivity.

Jib Crane for Warehousing and Supply

Storage

Electric lifting cantilever jib cranes that are commonly found in warehouses and supply storage locations, which improve the efficiency and speed of material handling. In many warehouses, electric hoist slewing jib crane is used as supplement and addon for the larger and more robust gantry and overhead cranes. They provide the precision and accuracy needed to put materials on trucks or place them on a production line.

Jib Crane Price

Selecting a electric lift jib crane to

match application requirements involves assessing key elements such as

operation type, structure, necessary options, cost of jib crane, and jib crane

installation. If you want to buy jib crane with an cost-effective jib crane

price, you are suggested to consider the following factors in selecting the

appropriate jib crane type:

- Span of Jib Crane/Boom Length: 2m 3m 4m 5m 6m 7m 8m 9m 10m?

- Rotation of Jib Crane: Free standing and mast type jib cranes offer 360 degrees of rotations while wall mounted cranes provide 270 degrees of rotation

- Rated Loading Capacity: 1 ton 2 ton 3 ton 5 ton 10 ton?

- Overall Height / Lift Height: 3m 4m 5m 6m 7m 8m 9m 10m?

- Power for motors, hoists, balancers: 220V~480V 3 phase

- Jib Crane Installation: Installation involves ease of assembly, and support needs

(whether or not a second-pour foundation or building supports are needed). Is

the workshop building ready? What is the depth of the concrete floor? Is the

surface flat? Do you have the correct i-beam or structural posts for the crane?

Jib Crane Manufacturer in China

YUANDA is a leading jib crane supplier in China, supplying various of material handling and lifting systems to our distributors and directly to end users both in China and overseas. We ship all over the world including the United States, Canada, Indonesia, Mexico, Chile, Peru, UAE, Middle East, Saudi Arabia, Australia, European, the United Kingdom, EU, and more. All our jib cranes are CE certified.

Fixed floor mounted jib crane design

drawings and operation manual can also be provided by our technical team.

Contact us now for jib crane price.