Jib Crane

10 Ton Jib Crane for Sale

10 ton jib cranes are versatile and efficient solutions for lifting and moving heavy loads in various environments. They are ideal for workstations, warehouses, production lines, and anywhere you need to lift and transport heavy items with precision.

Lifting capacity: 10 Ton

Models: BZD BXD BD BZ

Span: 3m 4m 5m 6m 7m 8m 10m 12m 15m

Control Method: Ground control+Remote control

Lifting mechanism: Low headroom electric chain hoist, electric wire rope hoist

Lifting speed: Dual speed or variable speed (custom)

Mount type: Ground foundation mounted

Power supply: AC-3Phase-220/380/400/415/440V-50/60Hz

Work duty: A3-A5

10 Ton jib crane manufacturer: China supplier

10 Ton jib crane price: $5000.00~$20,000.00

10 Ton Jib Crane for Sale

10 Ton Jib Crane Design

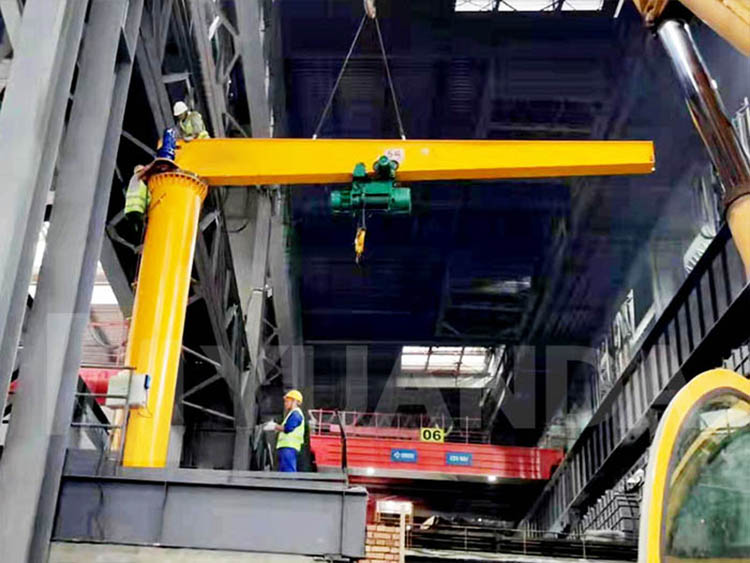

The heavy duty 10 ton pillar base mounted jib crane is ideal for processes that involve heavy lifting and constant use throughout the day. Fully customizable, this self supporting 360 degree rotating jib crane mounts to the floor using heavy duty anchor bolts and recommended foundation, providing stability and strength to lift and transport heavy loads. 10 Ton floor mounted jib cranes consist of a vertical support pillar firmly attached to the ground, from which a horizontal jib arm extends out. This arm can rotate along a full 360-degree radius, allowing for precise positioning of loads in different directions.

10 Ton free standing jib cranes are favored for their ability to efficiently cover specific work areas without the need for extensive structural modifications. They are widely used in workshops, warehouses, manufacturing facilities, and loading docks where lifting operations are frequent. With diverse configurations and options, 10 ton workshop jib cranes offer a practical solution for optimizing workflow, reducing labor cost, and enhancing work efficiency.

Features of 10 Ton Jib Crane

Rated lift capacity: 10 ton(tonne/tn/metric ton/MT) 15 ton 16ton

Heavy loading weight: 20000lbs

SWL/WLL: 10t 15t 16t

Crane feature: Heavy duty

Swivel angle: 180° 270° 360° degree rotating jib cranes

Height/Span: 10ft. 12ft. 15ft. 18ft. 20ft. 30ft. 25’ 28’ 30’ 35’

Height Under Boom (HUB):5ft 7ft 10ft 12 ft. 2 3 4 5 6 8 9 10 11 12 m meters

Overall Height: 5ft 7ft 10ft 13 ft 15ft 20ft 2m 3m 4m 5m 6m 8m 9m 10m 12m

Foundation Width: 2ft 4ft 7ft.

Foundation Size: 9’ x 9’ x 4’

Anchored bolts must be set in wet concrete ground

Crane color: Safety Yellow, Ocean Blue

Axial Load: 10 tone

Hoist & Trolley Allowance: 10 ton

Base mounted: Yes

Coverage: 360° circular rotation

Standards: FEM; AISC ASME B30.20; ASME B30.9; ASME BTH-1

I beam construction for 10 ton swing jib crane

Heavy duty assembly with reinforcing side plates

Full plate style gussets for maximum load distribution

Adjustable collar style rotation stops

Top entry collector ring & mounting plate

Control: Pendant control penal, wire control or wireless radio remote control jib crane

IP55 IP65 IP56 Protection for motors & panels

Applicable industries: 10 Ton jib crane for workshops, building material shops, machinery shops, manufacturing plant, factory, warehouse, construction works, energy & mining, indoor and outdoor.

All YUANDA Industrial Jib Cranes have a design factor of 15% of the allowable capacity for hoist weight and 25% of the allowable capacity for impact.

Heavy Duty 10 Ton Jib Crane for Sale

Heavy Duty Stationary Fixed Type 10 Ton Floor Mounted Jib Crane in Workshop

10 Ton Fixed Column Mounted Cantilever Slewing Jib Crane with Electric Hoist

10 Ton 360 Degree Slewing Electric Lifting Pillar Type Cantilever Jib Crane for Sale

10 Ton Gound Foundation Electric Hoist Jib Crane for Sale

10 Ton Marine Boat Lift Jib Crane on Port Shipyard Marina

10 Ton Jib Crane Accessories, Components and Jib Crane Parts

It is essential to understand the machinery mechanism when working with a 10 ton cantilever jib crane. Understanding the parts that a 10T jib crane for sale is composed of, is key to proper maintenance and avoiding damage and injuries. Let’s review the key components so you can properly operate and maintain your overhead jib crane with safest conditions.

Movable Hoist – The hoist positions, lowers, and elevates the loads.

Hook Height – This refers to the maximum height of the hook above a base level.

Electric Hoist – It can either be wire rope hoist or chain hoist. The total hoist allowance is 15% of the stated capacity. Jib crane with electric hoist, hoist brand: Demag, Abus, Kito, KONE, YUANDA, YALE, PLANET, Gorbel, etc.

Rotation Stop –The rotation stop will limit movement if the swing arm jib crane is near a wall or other structure to avoid damage.

The Reach – This is a horizontal beam that swings back and forth, where hoist and trolley are located on.

Controls – This allows the operator to control the crane with a push-button controller or remote control.

Mast or Pillar – This refers to a vertical beam that’s either freestanding or floor mounted. It supports the boom loading system.

Other components includes: Jib crane motor and reducer, jib crane bearing, festoon cable system, safety devices, etc. We’re here for all your 10 ton overhead jib crane needs. We offer the best material handling solution and after sale service for our clients.

Technical Parameters of 10 Ton Jib Crane

BZD Type 5 Ton Electric Pillar Slewing Arm Jib Crane with Electric Hoist | ||

Capacity | ton | 10T jib crane for sale |

Control method | Electric rotation or wireless remote controlled jib crane | |

Valid radius | R(m) | 3m 4m 5m 6m 7m 8m 9m 10m jib crane 12m 13m 14m 15m |

Lifting height | m | 3m 4m 5m 6m 7m 8m 9m 10m or custom |

Lifting speed | m/min | 7/0.7 (High speed + Low speed) |

Trolley speed | m/min | 10 |

Slewing speed | r/min | 0.5~1 |

Slewing angle | degree | 180° 270° 360° slewing jib crane |

Work duty | 10 Ton heavy duty jib crane | |

Control voltage | 24V 48V for control panel | |

Power supply | Motorized rolling jib crane or 380V 3Phase electric powered jib crane | |

*10 ton capacity heavy jib crane specifications may be subject to change without notice

10 Ton Jib Crane Application

A 10 ton pillar mounted jib crane, also called pole mounted jib crane or post mounted jib crane, is fixed on ground and to lift heavy loads. Available in many types and sizes, 10 ton electric hoist jib cranes are popular in a variety of applications. Common applications for these cranes are factories, workshops, workstations, construction sites, warehouses, ports, indoors, outdoors, and power plants.

In details, 10 ton column mounted jib cranes are used in maintenance and repair operations because they are capable of reaching small and hard-to-reach areas with precision. This type of crane is ideal for welding, painting, and the repair of machine parts. 10 Ton workstation jib cranes can also be used to safely transfer materials between workstations, eliminating the need for workers to lift and move heavy objects. 10 ton industrial jib cranes also provide heavy-duty support in industrial lifting operations with their advantage of superior lifting capacity and maneuverability, workers can hoist and transfer heavy objects with ease.

Finally, these 10 ton foundation jib cranes also have applications within the aerospace industry. Aerospace engineers use electric jib cranes to move and assemble parts of aircraft, space shuttles, and other vessels. The 10 ton swivel jib cranes are known for offering flexibility and stability, allowing engineers to move large objects precisely and safely. And the hoist lift jib crane can also be used for shipyard, called marine jib crane or port jib crane, boat lifting jib crane. These 10 ton marine jib cranes are designed specifically for moving boats on the marina.

For some extreme environments, 10 ton jib crane for outdoor or specific application, can be designed as galvanized jib crane(zinc coated), stainless steel jib crane or explosion proof jib crane as per specific requirements. Any place that requires the lifting of heavy objects can benefit from 10 ton jib cranes. If you have requirements to buy jib crane, contact us today. We provide the best jib crane service and jib crane price offer for our clients.

10 Ton Jib Crane Installation

Installing a 10 ton floor-mounted jib crane requires careful planning and attention to ensure safe and efficient operation. Some important factors to consider during the installation process are listed as below:

1. Site Assessment: Before installation, conduct a thorough assessment of the site. Ensure that the ground floor is structurally stable and capable of supporting the crane's weight and the loads to be handled. Check out if there is any obstacles, utilities, or obstructions that might affect the crane's normal movement.

2. Foundation: Properly anchor the vertical support pillar of the jib crane to a sturdy foundation. The 10 ton jib crane foundation must be capable of withstanding the crane's loads and forces. Consult our engineers now for the specifications related to anchor bolt size, depth, and spacing.

3. Headroom Clearances & Lift Height: Determine the required space around the jib crane's swing radius. Make sure there is sufficient space to safely rotate the crane arm without hitting walls, equipment, or other structures. Mostly important, the vertical stoke from the floor to the bottom of the crane's boom should be sufficient to accommodate the loads being lifted.

5. Electrical Power Supply: Arrange for the necessary electrical connections to power the crane, hoist and trolley. Ensure that the power supply meets the crane's voltage and amperage requirements.

6. Assembly and Alignment: Strictly follow the manufacturer's instruction manual for assembling and aligning the crane components. Accurate alignment of the jib arm and support pillar is crucial for proper operation.

7. Bolt Tightening: Properly tighten all bolts and fasteners according to the manufacturer's specifications. Loose bolts can compromise the crane's stability and safety.

8. Hoist and Trolley Installation: Assemble and attach the hoist and trolley components to the jib arm.

9. Safety Devices: Install safety devices such as limit switches, emergency stop buttons, rubber buffer and warning signs. These measures enhance the overall safety of crane operations.

10. Testing and Inspection: Thoroughly test the crane's movements, hoisting capabilities, and safety features before putting it into daily operation. Conduct a load test to verify the crane's normal performance. And finally, it is necessary to provide training for the crane operators to ensure they understand the safety procedures and proper operation of the crane.

12. Regular Maintenance: Establish a jib crane maintenance schedule to inspect, lubricate, and maintain the crane components. Regular maintenance prolongs the crane's lifespan and ensures safe operation.

Proper installation of a floor-mounted jib crane is essential for its safe and effective operation. If you're unsure about any aspect of the installation process, please feel free to consult with our experienced professionals for 10 ton jib crane installation.

10 Ton Jib Crane Price

To have a general idea of the 10 ton harga hoist jib crane cost which precisely suits your operational requirements, you'll need to provide specific parameters and details of the 10 ton pedestal jib cranes you need to the manufacturer or supplier. Here are the key parameters needed to customize a jib crane:

1. Lifting Capacity: Specify the maximum weight the crane needs to lift. In this case, it's 10 tons.

2. Lifting Height: Define the vertical distance from the floor to the highest stoke point the hoist's hook. It mean how many meters the load have to be lifted up.

3. Boom Length: Determine the horizontal reach of the jib arm(work range or work radius).

4. Rotation Angle: Specify the range of rotation needed for the crane's jib arm. Common angles are 180 degrees or 360 degrees.

5. Power Supply: The available power supply at your country or work site, including voltage, phase, and frequency (e.g., 220V, 240V, 380V, 400V, 440V 3-phase, 50Hz).

10 Ton Jib Crane Manufacturer in China

As one of the leading jib crane suppliers and manufacturers in China, we are proud to offer a wide range of high-quality jib cranes designed and manufactured to meet your specific lifting needs. We have also exported to many countries such as Saudi Arabia, Australia, European, United States, Canada, Indonesia, Mexico, Chile, Peru, UAE, Malaysia, Middle East, the United Kingdom, EU, and more. All our jib cranes are CE certified. If you want to buy 10 ton jib crane, our professionals will design and suggest a custom jib crane for you. 10 ton jib crane drawings, operation manual or jib crane design calculation can also be provided by our technical team. Contact us now to get the 10 ton jib crane price.

Related Products

Manufactured by 304 or 316, the stainless steel jib cranes with electric chain hoist are corrosion-resistant and ideal for food, pharmaceutical, medical, chemical industries and clean room, laboratory application. Lifting capacity 50kg, 80kg, 100kg, 250kg, 500kg and 1 ton.

Lightweight 500kg freestanding jib crane with electric hoist can be ground floor mounted, pillar mounted, column mounted, wall mounted or portable type. Either on foundation or foundationless, 1/2 ton jib crane is used for workshop, warehouse and workstation. Get 1000lbs jib crane price from China supplier now.

Heavy duty 5 ton freestanding jib crane with electric hoist, is designed as ground floor mounted, pillar mounted, column mounted or wall type. Fixed on concrete foundation, it is widely used for workshop, warehouse, workstation, indoor and outdoor for lifting. Get 5 ton jib crane price from China supplier now.