Material Handling Equipment

Material Handling Equipment for Sale

What is Material Handling Equipment

Material handling equipment encompasses a wide range of machinery and tools designed to transport, control, protect, and store materials throughout manufacturing, warehousing, distribution, and disposal processes. This category includes forklifts, pallet jacks, cranes, hoists, and automated storage and retrieval systems. Such equipment enhances efficiency, safety, and productivity by reducing manual labor, minimizing product damage, and optimizing space utilization.

Typical applications for material handling equipment are for example handling of shipping containers, bobbin, heavy rolls, paper reels, sanitary ware, keg, aluminum foil, crates, bins, storage tanks, buckets, baggage, cases, forged parts, electrical cabinets and various vehicle parts such as engines, motors, gearboxes, tyres, shafts, and many more. Advanced material handling solutions often integrate automation and robotics, facilitating seamless operations and improving supply chain management. Investing in the right equipment is crucial for businesses seeking to streamline workflows and maintain a competitive edge in their industry. YUANDA company has a wide selection of material handling solutions designed to cater for a wide range of applications in any environment from construction to warehousing.

Overhead hanging garment conveyors are a premium garment handling, storage, retrieval, transport, delivery, sorting conveyor system. The monorail systems are used for uniform and clothes in laundry, factory, warehouse and production line.

Automated Electrified Monorail System(EMS) is an overhead conveyor system which contain individually motorized carriers that draw energy from an aluminum track mounted bus bar and transport pallet loads throughout automotive assembly line.

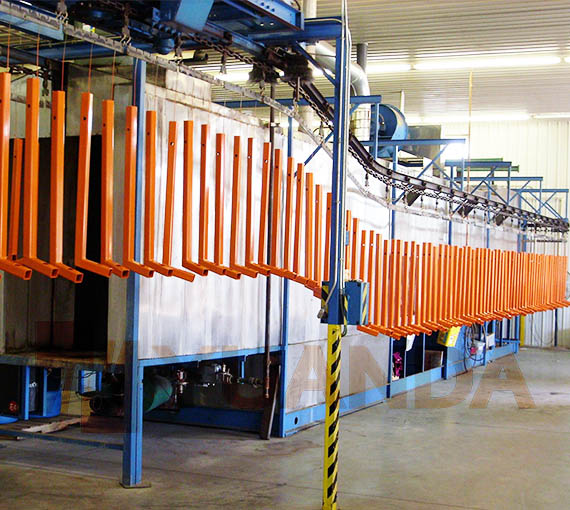

Either enclosed track or I beam type, manual overhead conveyor system is a hand push-pull monorail trolley conveyor, used for spray painting, powder coating line, assembly line, carton, garment, surface treatment, automotive industry, and finishing system.

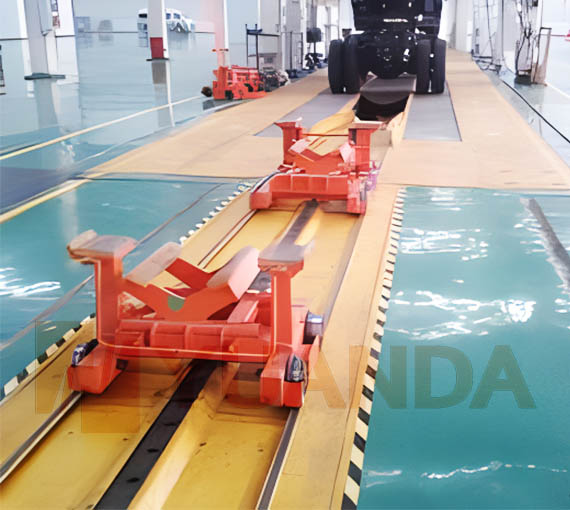

In floor mounted towline conveyor system is an inverted chain conveyor designed to pull carts along a factory ground floor, used in assembly lines, manufacturing plants, surface treatment industry, finishing, spray painting, powder coating and warehouses.

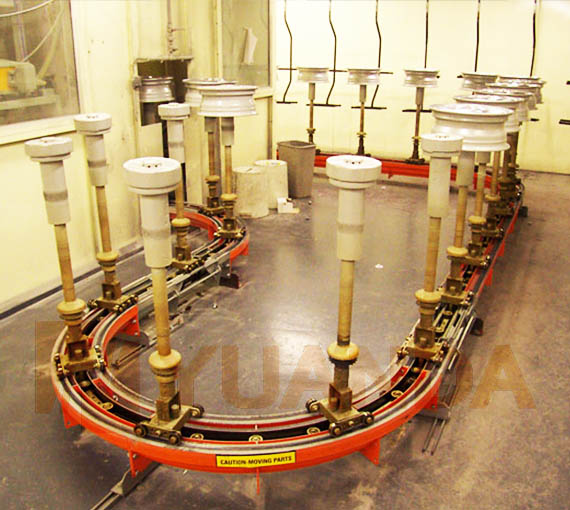

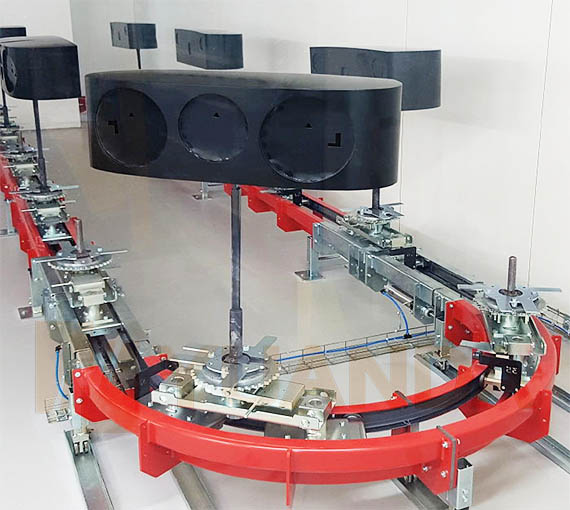

Inverted power and free conveyor, is a reversed floor mounted conveyor. This P&F inverted chain conveyor system is typically used in assembly lines, manufacturing plants, surface treatment industry, finishing, spray painting, powder coating and warehouses.

Inverted Floor Mounted Chain Conveyor is a reversed conveyor system installed on ground floor. This inverted floor track system can be either Power & Free with accumulation or monorail type.

The inverted floor conveyor is an inverted chain conveyor system mount on floor level. It can be reversed monorail track or inverted power and free conveyor type, widely used in assembly lines, workshops, surface treatment industry, finishing, spray painting, powder coating and manufacturing plants.

Overhead Conveyor System for Spray Painting Line is monorail overhead chain conveyor. Either I beam, enclosed track, or power and free, the spray painting overhead conveyor system transports workpieces through paint booth, drying oven for surface finishing process in paint shop.

Clean, quiet, low noise, fast speed, the friction drive conveyor system is an ideal alternative for monorail overhead and inverted power & free conveyors. This chainless aluminum tube track system is used for spray painting, powder coating line, e-commerce industry, logistic, carton, garment, surface treatment, automotive industry, assembly and finishing system.

Overhead monorail chain conveyor can be aluminum tube, I beam trolley, enclosed track, power and free, or inverted floor mounted type. The monorail system is used for spray painting, powder coating line, carton transfer, garment, surface treatment, automotive industry, and finishing system.

Either I-beam or enclosed track, monorail overhead conveyor system features clean, fast speed, low noise. This aluminum tube track system is used for spray painting, powder coating line, e-commerce industry, logistic, carton, garment, surface treatment, automotive industry, assembly and finishing system.

Overhead Power and Free Conveyor, is a chain conveyor system with two rails. This P&F overhead conveyor system is used for assembly lines, workshops, manufacturing plant, surface treatment industry, automotive industry, spray painting, finishing system, powder coating line and automobile industry.

Material Handling Equipment

Different Types of Material Handling Equipment

Material handling equipment is any machine or tool that is used to transport, process, store, or package materials. For example, mechanical arms, forklifts, overhead chain conveyors, shelves, and even autonomous mobile robots (AMRs).

Using material handling and warehouse equipment

improves efficiency and can help automate processes that would otherwise

require a lot of manual labor, saving you time and money. Common uses for

material handling devices include processing agricultural products like grain,

organizing and storing inventory in a warehouse, and loading and unloading dirt

or hardscape pick and carry the load to target place.

4 Key Types of Material Handling and Lifting Equipment

1. Workshop Material Handling Equipment

Industrial Manipulator

Industrial manipulator arms, also known as robotic mechanical arms, are the perfect ergonomic solution for material handling applications and reliable lift-assist solutions for your industrial assembly process. These lift assists arms and pneumatic industrial manipulators can have end effectors and gripper tooling custom designed for all of your heavy lifting requirements.

With your operators' safety at the forefront of our ergonomic designs, we take pride in our ability to answer your material handling needs with a mechanical lift-assist system. Our engineered part and material handling manipulator arm systems range in capacity from 100kg up to a massive 500kg.

Industrial manipulator robots are efficient material handling equipment for drum, barrel, cardboard box, steel coil, profiles, steel metal sheet, tube, pipe, wood panel, marble & granite, stone, auto parts, chassis, wheel hub, TV panel, LCD&LED screen, battery and more.

Overhead Chain Conveyor

An overhead conveyor system is an effective way to maximize space within your warehouse or production facility by moving materials and parts from one location to another above your workspace. Our company provides overhead conveyor systems designed for a wide range of industrial material handling operations including: parts handling, overhead storage and assembly lines in manufacturing and empty carton handling systems in distribution centers. Within the finishing industry, YUANDA paint shop conveyors have been used to move products through processing such as spray-painting, dip painting, plating, e-coating, powder coating, finishing system, sandblasting and cleaning. Our conveyors are also designed for garment handling, and a range of unique retail, creative and entertainment industry applications.

2. Bulk Material Handling Equipment

Bulk material handling equipment is specifically designed to transport loose bulk materials and is often used to move materials within food and chemical production.

This covers handling equipment including hoppers, reclaimers and conveyor belts.

●Hoppers and chutes. These

components are typically positioned at the start of the bulk material handling

and processing system. Hoppers store bulk material, while chutes feed it into

the system.

●Silos: Silos are tall, cylindrical containers that provide

high-volume storage for items like coal, woodchips, or feed.

●Conveying equipment. Conveying equipment transports bulk material

through the processing facility and throughout the operation. This equipment

can take several forms, including (most commonly) belt conveyors, pneumatic

conveyors, chain conveyors, flexible screw conveyors, and bucket elevators.

●Trippers. Trippers are also specific to belt conveyors. These

components divert the flow of material in the processing line by creating

discharge—i.e., off-loading—points at various locations. Stationary trippers

are used for discharging materials at a fixed spot, while mobile trippers are

used for applications requiring large material stockpiles, or material

distribution over a large area.

●Stackers and reclaimers. As their names suggest, stackers are used

for accumulating and storing material in stacks, and reclaimers are used for

retrieving material as needed. Traditionally, the two components were employed

as individual units. However, in modern bulk material handling and processing

systems, stackers and reclaimers are typically combined into a single,

multipurpose unit.

●Bucket elevators: A bucket elevator, also called a grain leg or

grain elevator, hauls flowable bulk materials vertically. It’s typically used

in an agricultural setting, moving loose materials or agriculture products like

grain or fertilizer.

●Bulk-handling cranes: Building on the design of a basic crane, a

bulk-handling crane includes a two-piece hinged grab to lift and balance bulk

cargo like metal scrap, waste, coal or mineral ore. It is usually used at garbage

dump, waste treatment plant or power plant.

●Dump trucks: An EV battery operated dump truck is a vehicle designed

for transporting and unloading large quantities of materials. It’s often used

in construction to offload or haul away debris or loose materials.

●Mobile ship loader

Belt conveyor ship loader can handle a broad range of commodities including lumpy, granular and sticky materials, such as coal, ores, minerals, grain, feedstuff and fertilizers. They benefit from low energy consumption and can load bulk carriers up to 3000 tph. Belt conveyors can be covered to protect cargo and minimize environmental impact and spillage.

Bulk material handling refers to the use of equipment to handle, process, and transport dry bulk materials, such as powders, granules, flakes, chips, and pellets. In processing facilities, bulk material handling systems move raw materials between the stations of the production line and transfer finished goods to the storage and shipping areas. The use of these systems—especially automated ones—is essential to operations in a wide range of processing industries, including chemical, cosmetics, electronics, food and beverage, mining, and textiles.

3. Industrial Trucks

The term industrial truck covers an extensive range of equipment, from small, manually operated tools to large, motorized vehicles.

Some of the main types of industrial trucks

are:

- Forklifts and forklift attachments

- Hand truck

- Pallet truck

- VNA truck

- Electric tow tugs

Electric forklifts are used in many industries to transport goods and materials and are available as battery-powered units or with a traditional combustion engine design. This industrial truck features forks at the front that can be raised or lowered to lift loads such as pallets or crates.

A versatile battery operated small electric aircraft tug is an optimal solution to move heavy loads including aircraft, luggage, and cargo. Our electric tug tractors are compact and easy to use.

4. Engineered Systems & Advanced

Material Handling

Engineered and automated material handling systems are typically more complex than other material handling equipment and can often include multiple pieces of equipment. Our company has designed material handling equipment that are currently in use by hundreds of different industries, including automotive industry, metalworking, sanitary, assembly lines, machinery manufacturing plant, food & beverage factory, mechanics, logistics, machine tools, energy & mining, oil & gas, textile, renewable energy, die casting, furniture, paint production, plastic industry and many more. Here are some of the most common types of engineered material handling systems:

●Automated guided vehicles (AGVs)

Autonomous load-moving systems designed to mobilize loads throughout processes while interacting with the environment.

●Automated storage and retrieval systems

Typically utilizes robotics to automate warehouse operations, including picking and processing to interact with storage racks and existing storage equipment.

●Robotic delivery systems

Which automate tasks such as pickup and delivery using robots programmed with specific instructions

●Automated conveyor systems

Move components swiftly between various processing points

●Palletizers

Palletizers replace the need for humans to load pallets. They stack items on a pallet and release the pallet onto a conveyor for further processing.

●Sortation systems

Sortation systems can automatically detect objects and route them to the desired location.

●Warehouse robots

Warehouse robots are AI designed for use in warehouse applications to automate simple, repetitive tasks, like picking products off of a shelf.

Other Types of Material Handling Equipment

Alongside the four key types of material handling machines, other types of equipment are available such as vacuum handling equipment, pneumatic handling equipment, material handling cranes, vacuum handlers, overhead bridge cranes, hoists, skate systems, scissor lift tables, aerial lift platforms, dock equipment and many more. Depending on the workpiece to be handled, the material handling equipment can be divided into the following types: plastic film roll handling equipment, drum handling equipment, carton handling equipment, glass handling equipment, container handling equipment and so on. Either mobile portable type or stationary type. In addition, the material handling equipment is widely used in virous industries. It is ergonomic solution for handling reels, plastic or paper rolls, laminated or plywood panels, windows&doors, rod bars, plates, ingots, boxes, sacks, bags, wheels, mechanical parts, automotive parts, and many more.

For some special application, we designed the practical version of stainless steel material handling equipment and cranes to withstand frequent wash-downs for industry regulations while maintaining the highest level of durability. Material handling solutions made from stainless steel are suitable for corrosive environments, particulate-controlled environments, and areas that are frequently cleaned and disinfected, such as food processing plants.

Material handling equipment is essential in

any setting where there’s material to be moved, lifted, stacked and

transported. Our company can provide you the highest quality industrial

material handling products, helps to improve safety and efficiency in your

warehouse.

Material Handling Equipment Manufacturer

in China

Material handling equipment covers a range of machines and systems used to move materials from one place to another or facilitate safe storage. It includes equipment for storing, transporting, and managing materials and products throughout production processes.

We take pride in manufacturing material

handling equipment that meets the most up-to-date design and safety standards.

We’ve supplied the material handling equipment for both small and large-scale

commercial and industrial operations, workshop, warehouse, clean room, and

manufacturing facility. From start-to-finish, we provide our customers with

custom design and engineering, installation, commission, service, and

maintenance on all types of material handling solutions including: robotic

mechanical arm, transfer carts, drum dollies, trucks and trailers, monorail

cranes, hoists, lift tables, loading dock equipment and much more. A wide

selection of material handling equipment meant to help you easily and safely

move and manage material in any environment. Contact us now for more

information.