Pedestal Rock Breaker Boom System

Pedestal Rock Breaker Boom System

Pedestal Rock Breaker Boom System For Sale

Static Pedestal Rock Breaker Boom System is a hydraulically operated manipulator mechanical arm fitted with hydraulic breaker hammer. When mounted near to the primary crusher it allows rock blockages to be removed and obstructions to be cleared. They are typically designed for use on JAW crusher, impact crusher, cone and gyratory crushers as well as other mining applications such as breaking oversized stone material on grizzly screen.

Our pedestal boom system breakers range consists of many different models with horizontal reach from 3m up to 18 meters. Manufactured from the high-standard quality materials to withstand the harsh and extreme environments, the range is built to ensure safety and increased production. Our pedestal rockbreaker boom systems have been successfully installed by industry leading firms at crushing plants, mineral and mining industries, which improves productivity and by preventing the crusher from clogging and averting bridging in hopper feeder and Jaw crusher. The fixed rock breaker boom is used to resize oversized material and also to rake obstructed or bridged material towards the crusher, ensuring that the primary crusher always operates at its full capacity. Therefore, the installation of hydraulic pedestal rockbreaking boom system represents a simple and highly cost-effective means for a mining crushing plant to eliminate some of the hazardous operation in the industry, which provide a steady flow of materials and increase safety around your primary.

Stationary Pedestal Rock Breaker Boom Systems, also known as Hydraulic Rockbreaker Boom Systems, are rock breaking equipment mounted at primary jaw, impact and gyratory crushers, stationary grizzly, mobile and portable crushers for quarry/mining rockbreaking application. Contact China supplier for price now.

China fixed type pedestal rock breaker boom system or rockbreaker boom system is a static, pedestal-mounted, hydraulic powered rockbreaking equipment mounted over the grizzly, primary jaw, impact, gyratory crushers, mobile and portable crushers for oversized rock breaking in quarry and mining plant.

Rock breaker boom hydraulic stationary manipulator arm is a fixed mechanical arm fitted with hydraulic breaker hammer. This rock breaking equipment is used in mining, quarry, aggregate industries and stone crushing plant to manipulate large rocks.

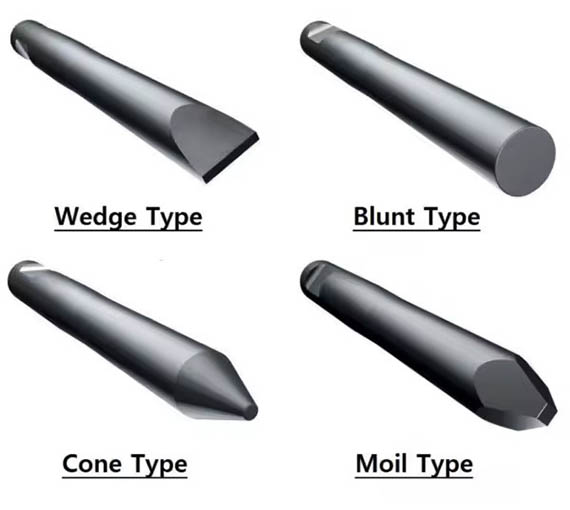

We supply hydraulic rock breaker tools for hydraulic hammers (hydraulic rock breakers) and heavy demolition tool bits. Sorted as breaker chisel, blunt, moil point, and cone type, the working tool is a key attachment, accessory and spare part fitting in a pedestal rock breaker boom system, which is used for rockbreaking, crushing at mine and quarry industry.

Pedestal Rock Breaker Boom System

Fixed Pedestal Rock Breaker Boom System

Features

- Model/Series: YZH, YD, WHB, IBS, TX

- Reliability for breaking light to medium

hard rock and stone

- Breakers: 750 1000 2000 3000 5000 ft. lbs.

- Reach: 14’ 18’ 20’ 25’ 26’ 27’ 28’ 30’ 32’ ft

feet (with hammer vertical)

- Boom length: 3 4 5 6 7 8 9 10 m meters

- Motor power: 22kw 30kw 35kw 40kw 45kw 50kw

55kw 75kw 100kw high breaking power

- Standard power pack: 20 30 40 50 60 75

100hp

- Heavy-duty construction, relatively light

weight, compact multipurpose boom

- Long reach and high breaking power

- Turntable: 170° 180° 360° degree swivel

angle, slew-bearing drive for constant swing torque

- Shock absorbing pedestal mounting

- Pedestal to concrete foundation kit / steel

structure mounting kit

- Dual row ball bearing slew with protected

internal gear and dual heavy-duty purpose-built hydraulic drive system

- Remote monitoring system is available when

it is equipped with 4G/5G technology for a wireless network connection

- Automated rockbreaking systems: Automation system for pedestal rockbreaker boom system can be developed, to provide collision avoidance and remote operation functionality.

- Pedestal Rock Breaker Boom System Price: $25,000.00-$150,000.00

Different Types Of Hydraulic Pedestal Rock Breaker Boom System

YUANDA is the fixed rock breaker boom supplier in the mining and quarrying industries. Over 20 years, we have been helping stone crusher plants power their productivity and break into profitability. We offer over a dozen different rock breaker system models for breaking oversize at large gyratories, grizzlies, jaw and impact crushers in stationary and portable applications. All hydraulic rockbreaker boom systems are custom fitted to your application for maximum endurance.

Heavy Duty Pedestal Rockbreaker Boom System for Primary Crushers

The YZH Series Pedestal Boom System has many new technical features that can handle workload with more capacity and weight and increase the productivity of the primary crusher. Designed to mount around the mouth of your crusher, a heavy-duty pedestal boom rock breaker eliminates the downtime associated with bridged or oversized rock material slowing down crushing operation. With a pedestal mounted boom and stick, hydraulic power pack, and heavy-duty hydraulic breaker, the pedestal boom system rock breakers are designed to rake material, break material, and keep your product flowing.

Mobile Pedestal Rock Breaker Boom System for Portable Crushers

YUANDA Series portable Rockbreaker Pedestal Booms are specifically designed for portable crushing plants. They have been proven to increase productivity by as much as 25% by removing bridged rock and breaking oversize in the hopper without stopping the plant or moving construction heavy equipment. Lightweight yet heavy-duty, these series fixed rock breaker boom systems can be supplied with its dedicated power pack or connected to the crusher’s hydraulic system. Optional wireless remote controls can be mounted in a loader operator’s cab, or traditional joystick controls can be securely mounted in an operator’s station.

Our technical teams will work with you to ensure the correct stationary pedestal rock breaker boom system is selected to meet your productivity goals. As a fixed rock breaker boom systems supplier, we provide an engineering drawing package with each rock breaking machine and rock breaking equipment, providing details for proper installation.

Applications of Pedestal Rock Breaker Boom System

We supply rock drill with a range of pedestal rockbreaking boom systems suited to different breaking applications, such as recycling, aggregates, and light-high rock breaking. This stationary type pedestal rockbreaker boom system is used to break up and crush granite, stone, ore, slag, concrete and other materials. A hydraulic rock breaker boom system can increase your quarry’s production by up to 30%.

When excavating and processing rock, the primary stone crusher becomes blocked by larger pieces of boulders, rocks, stones and it is precisely the fixed pedestal rockbreaker boom system which solves the dangerous and laborious problem of clearing these boulders in the crusher. It is also used during primary crushing on frames. The relevant parameters are chosen for the static pedestal rockbreaker boom system depending on the given use: size and method, reaches, lifting capacity, the size of the hydraulic hammer and the output of the hydraulic unit.

Pedestal Rock Breaker Boom System Used For Primary Jaw Crushers And Impact Crushers

Lighter types of rock breaker boom systems are used for primary jaw crushers or impact crushers, with smaller hydraulic hammers capable of breaking extremely hard and abrasive large rocks. The rock breaker boom system is used to break up oversized pieces in the crusher or to free up the transport routes to the crusher.

Pedestal Rock Breaker Boom System Used For Primary Gyratory Crushers

Large and powerful rock breaker boom systems with large hammers constructed for continuous and heavy operation are intended for primary gyratory cone crushers. They are used to break up oversized pieces of crushed material.

Pedestal Rock Breaker Boom System Used For Mobile Crusher

In the case of mobile crushers small rock breaker boom systems are used which are fitted directly to the structure of the mobile crusher. This pedestal rockbreaking boom system is also called as portable rockbreaker.

Pedestal Rock Breaker Boom System Used For Crushing On Grid(Grizzly)

For this type of crushing a hydraulic pedestal rockbreaker boom system with a suitably massive structure and a powerful and strong hammer which crushes the rock on a horizontal grid with defined opening sizes. This is primary crushing under continuous operation.

We have a variety of fixed rockbreaker boom system models for breaking oversized rock material at large gyratory crushers, grizzlies, and both primary and secondary crushing applications. Visit each pedestal boom model page for additional images and specifications. If you require an operation manual, maintenance manual or pedestal rock breaker boom system price, please contact our sales department now.