Pedestal Rock Breaker Boom System

Fixed Static Hydraulic Pedestal Rock Breaker Boom System for Sale

Pedestal Rock Breaker Systems provide the means to maximize the rated capacities of crushers. They also provide a safer method to alleviate blockages at the crusher caused by oversized, wedged and bridged materials.

Horizontal Reach: 3~18m

Vertical Reach: 2.5~16m

Hammer Mass Weight: 250kg~4000kg

Lifting capacity at maximum reach: 1 2 2.5 3 Ton(tonne)

Models: YZH WHB IBS

Power supply: 380v 50Hz 3Phase

Control method: joystick control, wireless remote control, operator cab control

Fixed rock breaker boom supplier: China manufacturer

Pedestal Rock Breaker Boom System Price: $20,000~$50,000

Fixed Static Hydraulic Pedestal Rock Breaker Boom System for Sale

Static Pedestal Rock Breaker Boom System Design

YUANDA is a fixed rock breaker boom systems supplier in China. The series are extremely heavy-duty assemblies. Our stationary rock breaker is designed to carry hydraulic rock breaker hammer weighing up to 6000 lbs., energy classes to 8000 ft lbs., and is ideally suited for iron mining and stone crusher plant, serving large crushers, in gyratory dump pockets, over grizzlies, underground ore passes and other high production locations where large breakers are required. The rock breaker machines are made from high strength steel alloys, guaranteeing longevity and ensuring resistance to torsion and buckling. These designs are the beneficiaries of many years’ experience in providing rock breaking equipment to demanding mineral mines and crushed stone producers worldwide. The pedestal boom system rock breaker is mounted on an extra-large pedestal base with large diameter king-pins and swing post. Shock absorbing pedestal mounting increases stability. Its heavy duty tubular steel construction is reinforced in critical areas, built to last for years in even the most arduous working environments. The heavy-duty hydraulic cylinders of the fixed rock breaker boom can eliminate crusher blockages efficiently, provide smooth material flow and maximise productivity for longer periods.

Fixed Pedestal Rock Breaker Boom System Features

Model No./Series: B300 C350 C450 C500 C600 D300 M630 M550 XL940 XL1400 XL1200 XM750 XM600 XM500 XR600

Input power: 22kw 30kw 35kw 40kw 45kw 50kw 55kw 75kw

Hydraulic power: 25 30 40 50 75 100 125 Horsepower(HP)

Operating weight: 5000kg 6000kg 7000kg

Maximum boom reach: 3m 3.5m 4m 5m 6m 7m 8m 9m 10m 11m 12m 13m 15m

Horizontal reach: 20 24 28 30 32 34 35 36 38 40 42 45 ft/feet

Vertical reach: 16 18 19 20 21 22 24 25 27 28 ft/feet

Lifting capacity at maximum reach: 1000 2000 2500 3000 4000 5000 lbs (pound) kgs

Rotation angle: 170° 180° 330° 360° swivel

Pump Working Pressure: 200Bar

No. of jib arm: 2

Rock hammer rod tool diameter: 68mm 70mm 75mm 80mm 85mm 100mm 125mm 135mm 140mm 150mm 155mm 165mm 175mm

Ambient temperature: -20~40℃

Products manufactured to ISO 9001 standards

Ergonomic seat control

Pedestal design: swing post or turntable

Modular design, light weight

Heavy-duty cylinders

Heat treated conical pins

Joystick control & 5G automation remote control system(optical fiber cable)

Compatible with heavy duty rockbreakers

YUANDA is one of the pioneer manufacturers of Stationary Boom Rock Breaker System in China, offering total rockbreaking solutions for our clients. This fixed pedestal boom breaker system is suitable for underground mining, stationary rock crusher application and mobile crusher application to manage bridging, build ups and oversized rocks/stones. This hydraulic pedestal boom system breakers will allow crushers to achieve max. capacity and improve safety in mining and quarry industry.

Fixed Type Pedestal Rock Breaker Boom System Working On An Underground Mine Grizzly

Pedestal Boom Rockbreaker Systems

Static Type Pedestal Boom System Rock Breaker

Fixed Type Hydraulic Pedestal Boom System Rock Breaker

Hydraulic Rock Breaking Boom System

Underground Rockbreaker Systems

Bucket type Fixed Rock Breaker Boom System Stationary Excavator

Technical Parameter of Heavy Duty Hydraulic Pedestal Rock Breaker Boom System

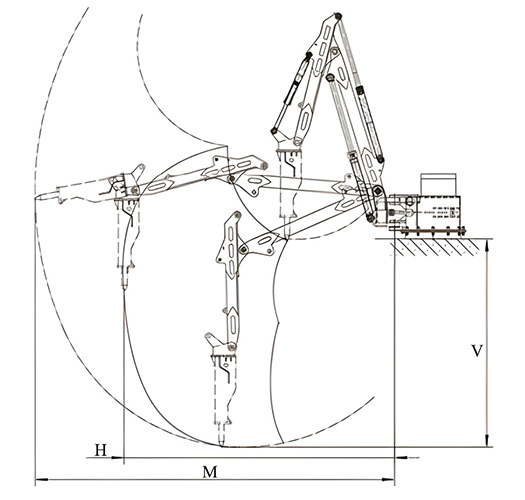

RANGE OF MOTION

The vertical range, horizontal range and working depth of the hydraulic pedestal boom rock breaker can be customized to meet customer specifications and local construction conditions.

Hydraulic Pedestal Rock Breaker Boom System Specifications

Name | Fixed Static Pedestal Rockbreaking Boom System |

Boom weight | 1400kg 6800kg 23000kg |

Input power | 18kw 30kw 35kw 40kw 45kw |

Maximum reach | 5.2 m 10m 18m 20m |

Nominal horizontal reach (H) | 3.5m 4m 6m |

Nominal vertical reach (V) | 3.8m 4.5m 8m |

Swing | 170° 360° |

Excavation depth | 3~16m |

Number of joints | 2 or 3 |

Base dimensions | 0.9 x 1 m |

Hydraulic breaker tool diameter | 3" 4" 5" 6" 7" 8" |

Impact rate for rock breaker hydraulic hammer | 200bpm~1000bpm |

Work duty level | High |

Application | Jaw Crusher Impact Crusher Blockages and build-ups Gyratory Crusher Grizzly Screen Primary rock breaking Underground mining |

*Hydraulic pedestal rock breaking boom system specifications are subject to change without notice.

Different Types Of Fixed Pedestal Rock Breaker Boom System

YUANDA, a fixed static hydraulic rock breaker boom system supplier, with decades of rock breaking experience in quarries and mines throughout China have merged with proven Static Hydraulic Pedestal Rock Breaker Boom System technology. We provide operators a reliable rockbreaking equipment that delivers a reliable performance and we offer clients the choice of many different series of fixed pedestal breaker boom models with a horizontal reach of 10 feet to 50 feet.

Light Duty Small Pedestal Rock Breaker Boom System

The small fixed rock breaker boom system is designed to tackle blockages and bridging in the crusher chamber. With a selected hydraulic rockbreaker, it provides a 4.5 meter maximum reach and 360° rotation for optimum flexibility. The fixed static hydraulic rock breaking booms system is designed for optimum durability and reliability.

Portable Mobile Rock Breaker Boom Systems

Our range of Mobile Boom Systems are designed for use on mobile crushers for the purpose of breaking oversize material. Their compact dimensions enable the boom to remain on the crusher during transport thus eliminating down-time on site for assembly and disassembly.

The mobile boom portable rockbreaker is generally powered directly from the mobile crushers’ own hydraulic system, therefore no need for a separate hydraulic power supply. For electrical powered mobile crushers we provide a full range of power pack units for our clients.

Heavy duty Hydraulic Rockbreaker Boom System

The light weight yet high capacity fixed hydraulic rock breaker boom system enhances productivity of stationary crushers by feeding material to the crushers and raking the hopper area.

The stationary rockbreaker boom construction has been designed to withstand tougher duty cycles, making the fixed pedestal boom system ideal for quarry and mining applications and even heavier applications such as underground grizzlies. Triangular boom design is light weight yet offering high capacity and the circular boom pedestal is designed to optimize stress distribution.

We offer the right hydraulic rockbreaking boom system for your specific rockbreaking needs. Today, YUANDA offers 8 series of fixed pedestal rockbreaker boom systems. Each engineered for a precise duty level that is ideal for a particular work place and its requirements. Please contact our sale department for each series, its specific duty level and reach coverage. Each model of our static rock breaker boom system is manufactured to the high standards of performance and reliability. If you need a custom rockbreaking solution, we will engineer a stationary rock breaker boom systems that is precisely fitted to your needs.

Static Pedestal Rock Breaker Boom System Applications

YUANDA, a China rock breaking booms supplier and exporter, has an extensive list of Hydraulic Boom Systems specifically designed for a number of different uses and environments. Whether you are in need of stationary pedestal rock breaker boom systems for gyratory crushers, jaw crushers, HSI Crushers, mobile crushers, modified excavators and booms, demolition grapples, underground equipment, robot excavators, hydraulic hammers, pedestal boom systems for mining or steel industry, recycling boom systems, or grizzly screen, any kind of crusher can be equipped with a YUANDA fixed rockbreaker boom systems.

Quarries

YZH series heavy duty rockbreaker booms are essential to avoid congestion at the crusher intake. Keep on working in spite of jams by installing a static pedestal breaker booms system that will overcome any eventuality and reduce downtime costs of your crusher. They are radio remote controlled and have 360° rotation. A complete range with a variety of reaches and features enable YUANDA to provide a custom rockbreaking equipment for your crushing plant.

Foundries

Foundries and steel mills are among the most aggressive environments for operation of any rock breaker machine. The unique design of the hydraulic stationary rockbreaker system will help to save time in the extraction of all slag and refractory brick. Benefits from their radio control system, Pedestal rockbreaker booms system provide total safety for the operator. They are suitable for areas where access of an excavator is too difficult. A complete range with a variety of reaches and features that enable the YZH design a team to tailor them to your plant.

Tunnelling

YZH series static pedestal rockbreaker boom systems are suitable for use in tunnelling applications where hazardous conditions and confined spaces preclude the use of heavy machinery.

The operator works in complete safety with radio controlled. This allows for the fixed pedestal mounted hydraulic boom systems to be operated from a safe location, where the operator can easily see into the breaking area.

Grizzly

Underground mining operations typically use a steel grate called a grizzly to size material before it enters an ore pass. Material that is too large to pass through the openings in the grizzly, is left on surface of the grizzly to be broken by a fixed hydraulic pedestal mounted rock breaker boom system.

Grizzly applications are extremely harsh by nature. The underground mining equipment is subject to high degrees of in-line and side raking, combined with various sizes and amounts of oversize. YUANDA grizzly stationary boom breaker systems are designed with wide boom cross sections, extra large pins and reinforced high tensile steel plates. All designed to handle complex loading to the boom.

Gyratory Crusher / Jaw Crusher

High work duty level jobs would need a bigger static pedestal booms system and hydraulic rock breakers. YUANDA’s wide range of gyratory pedestal breaker booms allow full breaker coverage within the hopper and mouth of the crusher. Ours complete line of large hydraulic hammers are designed specifically for gyratories to quickly eliminate any bridging or clogging, restoring consistent material flow for the crusher.

Mobile Crushers

Mobile crushers are construction heavy equipment which is designed to be moved from site to site. An appropriate sized hydraulic fixed rock breaker boom system will mount on the crusher to handle the raking and breaking.

Static Hydraulic Pedestal Rock Breaker Boom System Parts & Accessories

Our rocker breaker boom with pedestal mount for primary crusher are complete functional packages optimized for primary crushing applications. Each component, breaker boom, rock breaker, hydraulic power unit and radio remote control, is optimized to work most efficiently with the other components. And each complete solution is optimized to work most efficiently with different crushers. Each component is engineered to meet the requirements that the underground mining equipment can be used in rough primary crushing applications.

Pedestal base

Large 360 degree swing table. High performance ball-bearing swing gear assembly, hydraulic motor with planetary and pinion gears. Shock absorbing boom base.

Heavy Duty Hydraulic Cylinders

For hydraulic pedestal boom rockbreaking equipment safety and long life, boom and cylinder pins are made with diameters that exceed requirements. Cylinders are high strength, heavy duty designs with oversized rods and built-in cushioning. Hoses or tubes routed on top of boom to prevent interference and damage to the hydraulic line.

Hydraulic Power Unit

Heavy duty fabricated steel assembly with tank positioned above pump, includes electric motor (voltage per specs), coupler, pump(s), filters, oil level sight gauge, tank heater, oil cooler, low level and high temperature shutoff switches, etc.

Remote Control

YUANDA hydraulic rockbreaker systems come standard with dual joystick levers, offering fully proportional electro-hydraulic control combined with fully proportional, load-sensing directional control valve for precise control of all boom and breaker operations.

There are also CONTROL OPTIONS such as: Radio controls for safe long-distance operation at a distance, ergonomic seat with arm-mounted joysticks, which enhance operator comfort during operation. The hydraulic rock breaker system with remote control is also called hydraulic manipulator arm rockbreaker or hydraulic manipulator rock breaker. What’s more, we have developed the available automation system for pedestal rockbreakers, providing collision avoidance and remote operation functionality. The control can be upgrade with our Intel Control System(Teleoperation System). Maximize rockbreaking operations and creates a more secure working environment while easily connecting to your existing mining process control system by 5G network and optical fiber cable. With camera & display monitors, the control system features automated movement, operator cabin, Long distance control, force and speed control, real-time monitoring and diagnostics.

Support Steelwork Structure

A lattice frame steel support tower can be used to support fixed mechanical arm rock breaker equipment, which is designed to ensure structural integrity and to gain maximum capacity.

Other spare parts and Accessories of hydraulic pedestal rock breaker boom system includes: rock breaker hammer, hydraulic hammer drill rod tools, auto lubrication device, bucket attachment, quick coupler, operator cabin and so on.

Hydraulic rock breaker boom is a high strength articulating structure designed to manipulate hydraulic breaker hammers, rock grapples, and rock points. China rockbreaker boom system is designed for gyratory cone crusher and primary crushing of aggregate on grizzly screen. We will help you choose the right rockbreaker boom, controls and hydraulic power pack to suit the application and work with you to optimise the installation to ensure reliable operation and maximum productivity and serviceability.

Installation, Commissioning and Maintenance of Fixed Static Pedestal Rock Breaker Boom System

We provide personalized and comprehensive solutions and customer service, from project design, manufacturing and on-site delivery, to installation, commissioning, maintenance, user training and after sale service. The delivery of a product to a customer marks the beginning of a permanent service.

Regular maintenance for China rockbreaker boom system for gyratory cone crusher and primary crushing of aggregate on grizzly screen is the best way to ensure that it performs efficiently even in the harsh environments, maximising your investment and avoiding expensive unplanned downtime. YUANDA can play an active role throughout the lifecycle of your rockbreaking machinery, from pedestal rock breaker boom system installation, commissioning and maintenance. Our skilled, dedicated and experienced service team can provide realtime virtual assistance and troubleshooting.

Fixed Pedestal Rock Breaker Boom System Supplier/Manufacturer in China

YUANDA knows that rock breaker boom systems for jaw crusher and impact crusher consist of the strictly constructed booms as well as the rock hammers the industry has to offer. Focusing on the high product standard for performance and reliability, we have consistently been the choice of professionals in search of the stationary hydraulic pedestal boom rockbreaking solution. Based on years of experience, we can customize the proper boom/hammer configuration for your specific purpose. We have shipped our hammer stationary manipulators with a hydraulic breaker around the world including Netherlands, Poland, United States, Canada, Indonesia, Mexico, Chile, Peru, UAE, Middle East, the United Kingdom, EU, and more. All our fixed static hydraulic pedestal rockbreaker boom systems are CE certified.

Leave us a message now about your Automated Rockbreaking Systems requirements, we will prepare the pedestal rock breaker boom system price for you.

Related Products

Stationary Pedestal Rock Breaker Boom Systems, also known as Hydraulic Rockbreaker Boom Systems, are rock breaking equipment mounted at primary jaw, impact and gyratory crushers, stationary grizzly, mobile and portable crushers for quarry/mining rockbreaking application. Contact China supplier for price now.

Rock breaker boom hydraulic stationary manipulator arm is a fixed mechanical arm fitted with hydraulic breaker hammer. This rock breaking equipment is used in mining, quarry, aggregate industries and stone crushing plant to manipulate large rocks.

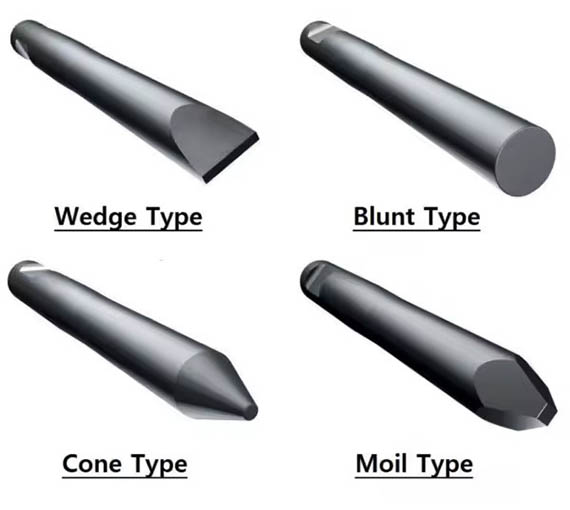

We supply hydraulic rock breaker tools for hydraulic hammers (hydraulic rock breakers) and heavy demolition tool bits. Sorted as breaker chisel, blunt, moil point, and cone type, the working tool is a key attachment, accessory and spare part fitting in a pedestal rock breaker boom system, which is used for rockbreaking, crushing at mine and quarry industry.