Overhead Conveyor System

Overhead Conveyor System For Sale

Overhead conveyors free up valuable floor space by moving conveying systems up above work areas. A continuous track is suspended either from overhead supports or ceiling mounted structure, and power chains with hangers are placed on the track that can hold product to be conveyed. Pendants of the monorail overhead conveyor system can be designed to accommodate a wide range of items, from light products like garments on hangers to heavy duty parts for assembly. The specific application and capacity requirements will determine the best type of overhead hanging conveyor for your project.

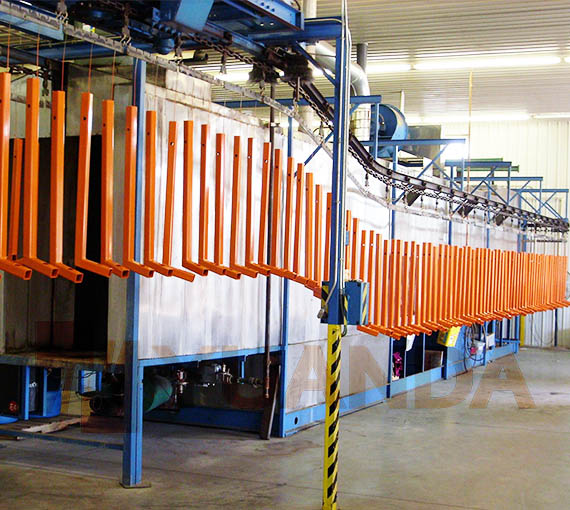

The Industrial Overhead Conveyor System offers many advantages in terms of the ability to transport and handle heavy loads and odd shaped items products, pieces or parts in powder coating plant spaces above the work area, incorporating cleaning, painting, heat treating, baking, finishing or similar operations. Benefits from its modular design, it can be easily modified if production needs change.

This overhead monorail chain conveyor system can be used in manufacturing requirements and automatic workstations to perform functions like transporting parts through paint curing ovens, paint booths or similar operations, delivery, loading, unloading, storage and scientific production management. The typical application including: overhead conveyor system for finishing system, powder coating line, liquid spray painting line, automotive assembly lines, product transport, process automation, vehicle body shop, manufacture plant, distribution and logistics, slaughterhouse, workshops, automobile production line and more industries.

Optimise the material handling process within your paint facility with the use of overhead chain conveyor systems. We specialise in automated and manual systems, Ranging from Overhead conveyors, Floor conveyors, Manual conveyors, Specialist conveyors. Take a look at the options below, you are able to choose the right type of monorail overhead conveyor system for sale that suits your needs.

Overhead hanging garment conveyors are a premium garment handling, storage, retrieval, transport, delivery, sorting conveyor system. The monorail systems are used for uniform and clothes in laundry, factory, warehouse and production line.

Automated Electrified Monorail System(EMS) is an overhead conveyor system which contain individually motorized carriers that draw energy from an aluminum track mounted bus bar and transport pallet loads throughout automotive assembly line.

Either enclosed track or I beam type, manual overhead conveyor system is a hand push-pull monorail trolley conveyor, used for spray painting, powder coating line, assembly line, carton, garment, surface treatment, automotive industry, and finishing system.

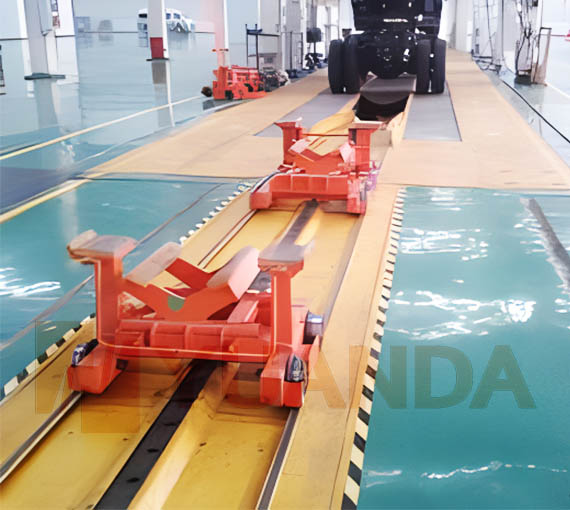

In floor mounted towline conveyor system is an inverted chain conveyor designed to pull carts along a factory ground floor, used in assembly lines, manufacturing plants, surface treatment industry, finishing, spray painting, powder coating and warehouses.

Inverted power and free conveyor, is a reversed floor mounted conveyor. This P&F inverted chain conveyor system is typically used in assembly lines, manufacturing plants, surface treatment industry, finishing, spray painting, powder coating and warehouses.

Inverted Floor Mounted Chain Conveyor is a reversed conveyor system installed on ground floor. This inverted floor track system can be either Power & Free with accumulation or monorail type.

The inverted floor conveyor is an inverted chain conveyor system mount on floor level. It can be reversed monorail track or inverted power and free conveyor type, widely used in assembly lines, workshops, surface treatment industry, finishing, spray painting, powder coating and manufacturing plants.

Overhead Conveyor System for Spray Painting Line is monorail overhead chain conveyor. Either I beam, enclosed track, or power and free, the spray painting overhead conveyor system transports workpieces through paint booth, drying oven for surface finishing process in paint shop.

Clean, quiet, low noise, fast speed, the friction drive conveyor system is an ideal alternative for monorail overhead and inverted power & free conveyors. This chainless aluminum tube track system is used for spray painting, powder coating line, e-commerce industry, logistic, carton, garment, surface treatment, automotive industry, assembly and finishing system.

Overhead monorail chain conveyor can be aluminum tube, I beam trolley, enclosed track, power and free, or inverted floor mounted type. The monorail system is used for spray painting, powder coating line, carton transfer, garment, surface treatment, automotive industry, and finishing system.

Either I-beam or enclosed track, monorail overhead conveyor system features clean, fast speed, low noise. This aluminum tube track system is used for spray painting, powder coating line, e-commerce industry, logistic, carton, garment, surface treatment, automotive industry, assembly and finishing system.

Overhead Power and Free Conveyor, is a chain conveyor system with two rails. This P&F overhead conveyor system is used for assembly lines, workshops, manufacturing plant, surface treatment industry, automotive industry, spray painting, finishing system, powder coating line and automobile industry.

Available in 3 basic chain sizes: 3”, 4”, 6”, or called X348 X458 X678 I beam overhead conveyor, is a monorail trolley track conveyor system used for surface treatment, automotive industry, finishing system, spray painting and powder coating line.

Enclosed track overhead conveyor system is a monorail chain conveyor used for spray painting, powder coating line, carton, garment, surface treatment, automotive industry, and finishing system.

Overhead Conveyor System for Powder Coating Line is monorail overhead chain conveyor. Either I beam or enclosed track, the powder coating conveyor system transports workpieces through paint booth, drying oven for finishing process in workshop.

Overhead Conveyor System

Features of Overhead Conveyor System

Product name: Overhead Hanging Conveyor

System

Conveyor model: 150 200 250 300 350 X348

X458 X678 XT80 XT100 XT160 Taiwan 5ton 7ton UH5075 Powertrack

Chain model: UH-5075 WF-350 WF-400 XF400

QXT150 QXT200 QXT250 QXT300

Chain pitch: 6" 8" 9" 10" 12" 14" 16" 150mm 200mm 250mm 300mm 350mm

Loading capacity: 50kg per trolley 100kg

250kg 300kg 500kg per trolley

Spacing: 3” 4” 6” 150mm 250mm 300mm 350mm

High drive speed: 1-80m/min. fast running speed

Control Systems for Automation

Safety devices: Anti-backup, Anti-runaway

Horizontal curves:

780mm 1000mm

Degree:

90° / 45° / 30° / 15°

Radius:

600mm 700mm 1000 mm 1200mm 1500mm

Vertical

curves: 500mm 600mm 800mm

Degree

(depending on work-load): 30° / 15°

Radius:

1000mm 1200mm 1500mm 2500mm

Attachments: H, U, Y shape hanger attachments, jigs, Ladder carrier. A wide variety of part hooks, swivels, indexers, load bars and custom designed carriers are available to handle your product.

Max.

Temperature: 250°C

Drive

unit: Caterpillar drive or sprocket

Speed:

Variable speed as standard (or custom)

Power

supply: AC-3Phase-220/380/400/415/440V-50/60Hz

Overhead

conveyor system manufacturer: China supplier

Overhead conveyor system price: $5,000~$80,000

Adjustable clutch protection protects each

drive unit and conveyor chain against overload.

Components: Suspend monorail track, Take-Up

units, inspection section, automatic chain lubricator.

Common suspension versions include:

• One-point turning device, with or without fixation.

• Load bar attached to 2 or 4 chain carriers.

Variable frequency drive (VFD) can added to

the electric motor

Product carrier: Shipping boxes or plastic

totes

Clean, clear, noiseless, silent, low noise,

fast speed

Orders are put together or returns are

collected quickly

Trolley storage of the trolley transport

systems: OCS overhead conveyor solutions increase storage density in the

Intralogistics industry

Compact layout, alternate routing

Fully Automated overhead conveyor system,

or integration of manual and automated sections in the same system

Conveyor is used for both E-commerce orders

(B2B/B2C) and replenishment

Reading technology: BCR & RFID

Efficient order picking system, efficient

material flow solutions

Designed for operating at high efficiencies

with minimum maintenance.

Design of software based on years’ experience

Track: Tubular section track, Square

section track, Square tubular, Enclosed C-shaped track

Track material: I beam construction, or

Hollow section enclosed C rail channel profile(C track) or Lightweight aluminum

alloy enclosed track design, aluminum profile rails, aluminum tube.

Using standard modular components

constructed for long life, bolted track connections increase ease of enclosed

track monorail overhead conveyor system installation and help minimize downtime

in the event of layout modification.

Applicable

industries: Monorail Overhead Conveyor System for powder coating line, electrostatic

spray painting line, automobile industry, aviation industry, workshops,

manufacturing plant, automotive industry, paint finishing line and assembly

lines, surface treatment industry, food and beverage, household appliances,

office equipment, pharmaceuticals, retail, warehouse, etc.

YUANDA may provide entire engineered industrial overhead conveyor systems on turnkey basis or components only as request, if you want to buy Overhead Conveyor System, please contact us for your complete design.

Different Types

of Overhead Conveyor System

Powder coating line overhead conveyor system and wet spray painting line overhead conveyor system are the most typical type of overhead hanging conveyors which are mounted above with products hung from it. Power chain or overhead monorail systems utilise a continuous chain running in or on a track. The heavy duty, drop forged power chain conveyor providing transport for a range of fabrications in the modern powder coating plant or workshop.

We offer an extensive range of aerial conveyor systems ranging from simple manual systems, through powered single line, inverted monorail system(IMS) to complex Power & Free conveyor systems. These different paint line conveyor systems have been developed for unit load weights from a few grams to 5ton. All the overhead conveyor systems have been typically used for surface finishing industry, automotive, body shop, paint shop, engine assembly, textile logistics and clothing logistics, E-commerce, intralogistics industry, omnichannel retail, carton delivery system, distribution and sorting, garment handling system, displays and entertainment in shopping malls and super market, industrial production and so on.

There are six main types of overhead conveyor: power chain or monorail overhead conveyor; power and free overhead conveyor; electrified monorail system(EMS conveyor); Electrified floor track systems; overhead trolley conveyor system; towline system. Each one is manufactured using a modular construction and standard components in different configurations.

The heavy-duty I-beam overhead conveyor is a monorail conveyor system where a chain rides on an i-shaped metal beam that is suspended horizontally from the ceiling. Items are transported on pendants or trolleys that hang down from the ibeam and are propelled by the chain. I-beam monorail overhead conveyors allow easier product handling in a variety of applications, including final assembly, paint finishing system, electrostatic coating, liquid painting, storage, and more.

The enclosed track overhead conveyors prevent contamination from reaching the chain and any open surfaces, reducing cleaning and maintenance costs. They are also named as overhead tube track system, powder coating track system or overhead enclosed track system. The drive chain is enclosed in either a round or box tube rail, with items transported on pendants or trolleys that hang down from the closed-track conveyor. Medium and heavy-duty tube chain conveyor systems are available to suit a variety of needs including manufacturing, e-coating and plating, cleaning and pretreatment, wood finishing, trash removal, and more.

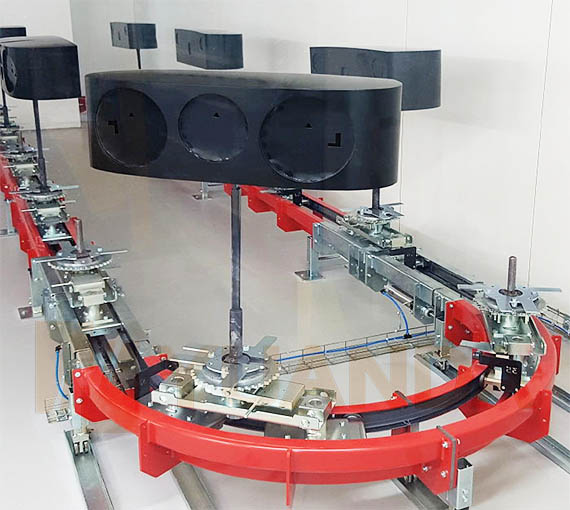

Power & Free overhead conveyor, also called asynchronous conveyor, has a twin track arrangement where a powered chain is mounted above a free running trolley track. These conveyors carry loads on individual pendants that can move at different paces, start and stop independently, and even change tracks. They are named for their two tracks – one powered and one “free” or unpowered(Dual track system). This design features high flexibility, allowing products to be diverted for various processes and accumulated for buffer storage.

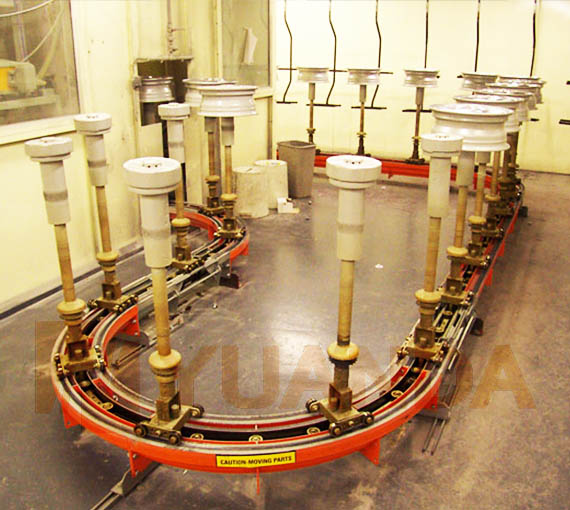

Overhead monorail system is a flexible, friction-based overhead conveyors for picking, sorting, storage and production solutions. The drive mechanism consists of a friction belt or a rotating tube driven by a worm gearmotor. Light weight due to its aluminum alloy profile tracks, this hanging conveyor features efficient, rapid speed, clean and quiet, with consistent and smooth transportation, whether it’s order picking, sorting, storage and retrieval, assembly or manufacturing. Furthermore, the entire production does not have to stop during any adjustments or if any errors occur (which is the case with chain driven conveyors). The friction drive overhead conveyors could meet the requirements imposed on lean conveyor solutions. It also used at supermarket, shopping mall for display, retail or carton delivery system.

Manual overhead conveyor systems are designed around a track with trolleys that are hand pushed by operators. These types of conveyors are ideal and cost effective when throughputs are relatively low. Junair’s manual conveyors are flexible, modular standard systems with customised solutions, such as powered sections in the conveyor circuit, vertical drop and lift sections and switching/turning gates. They offer a simple and reliable solution to your material handling problem. It improves ergonomics at loading points where heavy goods or work-pieces are handled, and can be used as a buffer zone or a storage facility between different steps in the production flow.

Electrified monorail conveyors, shortened as EMS conveyors, utilise individual motorised trolleys with an inbuilt motor controlled by a busbar coupled to the track.

A towline conveyor is an inverted overhead chain conveyor. It is also called ground tow cart conveyor. These floor conveyor systems are either mounted on or in the floor and are used to move products either directly from the chain on a jig or they can be used as a pushing or pulling medium for automatically moving products on work trolleys through various processes. The inverted floor conveyor systems include two main types: Monorail floor conveyors and Inverted Power & Free floor conveyors. Both of these two inverted floor chain conveyors can operate in a wide range of demanding industries.

Moreover, there are Skates & Rails conveyor systems. Bodyshops or automobile factory often utilise transfer systems, a vehicle is placed on lightweight aluminium skates and manually moved along rails from one area and process to the next. Skate and rail systems can be surface mounted, floor mounted or installed flush to the building floor.

With different loading weight or lift capacity, Overhead Conveyors can be divided as Light Duty overhead conveyor system, Medium Duty overhead conveyor system and Heavy Duty overhead conveyor system, ranging from 200 lbs to 1200 lbs per hook loading(Note: Load bars are available to increase hook loading). Constructed as different structure, Overhead Conveyors come in three basic styles: Round enclosed track overhead conveyor system, Rectangular enclosed track overhead conveyor system, and carbon steel I-beam overhead conveyor system, 3”, 4” and 6”. Including X348 I beam overhead conveyor system, X458 I beam overhead conveyor chain system, and X678 overhead conveyor chain system. Made by different raw material, there can be aluminum alloy overhead conveyor and stainless steel overhead chain conveyor. Sorted by different drive mechanism, they are grouped as overhead chainless conveyor system (chain-free conveyor), and overhead chain conveyor system. The chainless type includes monorail track conveyor, shuttle conveyor, pallet monorails system. The chain type includes: Drag chain overhead conveyor, overhead chain monorail system, overhead trolley conveyor system. Based on virous applications, the overhead conveyor can be made as powder coating chain conveyor system, sorting conveyors, property storage conveyor, automatic order assembly conveyor system, order picking system, retail display conveyor system, greenhouse conveyor system, order assembly conveyor, power tube pin conveyor.

The pretreatment overhead conveyor or electrodeposition overhead conveyor is used in the pretreatment, electrophoresis and electrodeposition process in a painting factory. It is a tact type conveyor by using electrical motor and electric hoist. The length of the processing device can be shortened compared to the continuous type conveyor. This overhead type conveyor has a lifting function and a traveling function separately. The automobile body can be mounted directly or mounted on the skid, either manually or automatically.

We also offer some special custom overhead conveyor systems for some special applications, such as: Pouch sorter, Skid conveyor system, Skillet conveyor system, Four wheels conveyor, Spindle line, Powered pallet conveyor system, Overhead transfers conveyor, Slat conveyor, Roller systems and Overhead slaughter conveyors for cattle, pigs and sheep.

The overhead transfer equipments increase efficiency by providing adaptive material handling and product transfer on the production line. The overhead conveyor systems are mainly sited in the following industries: automotive manufacturing and assembly line, powder coat system, industrial paint lines, wood industry, warehousing/logistics, surface finishing (wet paint and powder) and processing systems, laundry, food industry, dip lines, bicycle manufacturers, workshops, foundry and timber factories, auto parts transfer, textile transfer systems. The overhead conveyor system is for motorbikes, E-bike, aluminum profiles, hub, bicycles, furniture, gas cylinders, rubber tires, doors, windows, tote, pan, electronics, helmet, mobile phone shell, automobile parts, metal finishing, pallet handling and drum handling, carcasses, sheep, cow, cattle, poultry, widely used to handle various products in your workshop and finishing plant.

We have many different models of overhead conveyor system for sale, contact us online now for more details.

Overhead Conveyor System Accessories, Components

and Overhead Conveyor System Spare Parts

Overhead Monorail Conveyor Systems are an efficient and economical way to utilize area above the floor, which are also called roof ceiling conveyor. They are ideal for transporting parts through pretreatment cabins, drying ovens, paint booths or similar operations.

Overhead Conveyor Trolleys

Trolleys for overhead conveyor systems are the most basic component to consider when planning the trolley transport systems. Three basic sizes of trolleys–3″, 4″ and 6″, called as X348 X458 X678 trolley wheels. The brackets come in two styles: Drop Forged or Stamped(Wheels can be open or sealed depending on the application). There are front trolley and rear trolly in P&F conveyor system. Sometimes overhead trolleyless transport system or trolleyless conveyor sytem can also be a practical solution.

Overhead Conveyor Chain

Heavy duty trolleys or rollers connected by a forged rivetless chain ride on an I-beam monorail. The overhead chain systems come in 3 types: 3″, 4″ and 6″, namely X348 overhead conveyor chain, X458 overhead conveyor chain and X678 overhead conveyor chain.

Roller Turns

Roller bank curved rails offer the most economical means of providing overhead conveyor chain and trolley alignment during horizontal changes of direction. Rollers are available with double row ball bearings, tapered bearings or with a metalized carbon bearing.

Traction Wheel Turns

Overhead conveyor horizontal curved rails has many types, the traction wheel curved rails offer the most efficient means of maintaining chain and trolley alignment in horizontal turns. Chain pull is reduced because there is less turning friction and there is only one point of lubrication required reducing maintenance costs.

Tension Unit

180 Degree Take-ups maintain chain tension, reduce slack and ensure the smooth operation of the system. Take-up assembly is available with either the roller Turn or Traction Wheel Turn type construction, also known as Screw type, Spring type and Air type. Four “V” groove wheels provide true alignment for the floating frame section ensuring smooth trolley movement around the unit.

Motor Drive Device

Caterpillar Drives not only power the system but can also provide the desired speed range, speed control, reversibility or other special characteristics desired in the system. It is the key power unit of overhead conveyor parts. There are also Sprocket drive, friction drive and motor driven overhead conveyor system.

Control Systems for Automation

Automated control system is crucial to the efficient functioning of any conveyor system. Depending upon the complexity of the overhead conveyor system, control systems can range from simple start stop boxes to multiple control panels incorporating state-of-art PLCs and built-in HMI regulating numerous input and output devices, e.g. photocells, sensors, RFID, bar-code scanners, drive units etc. These provide a high degree of machinery control and enable the materials handing and conveying processes to be fully automated making them more efficient with resultant gains in productivity and ROI. Management data can also be provided e.g. error logging, throughput, product traceability, system downtime etc. Other features such as product tracking, system diagnostics, maintenance alarms and remote monitoring can be incorporated.

The ability of modern PLC’s to communicate with each other means that a conveyor system can be integrated into larger automated process plants if required. Our company design and implement bespoke control systems for any size and complexity of automated overhead conveyor system or material handling system. In the process we will ensure that the performance of all hardware is optimised. PLC manufacturers we have experience with include Siemens, Rockwell, Mitsubishi and Omron.

Overhead Conveyor Attachments

A wide variety of part hooks, swivels,

indexers, load bars and custom designed chain carriers are available to handle

your product.

Load bar: 500 lbs 1000lbs 2400 lbs capacity

90 degree indexing swivel hook type

90 degree star wheel indexing swivel

Rotary Rack Swivel hooks

Spinner hooks

C Shape Sanitary hooks

Other monorail overhead conveyor components include: Straight rails, heavy duty universal link conveyor chain, Fully automated trolley, Overhead conveyor belt, Straight track, Switches, Powered trolley rails, Jigs, Electric cars, Drop forged rivetless chain, Lifting and lowering stations, Horizontal turn, Vertical curves, “Power” profile with chain, “Free” profile with trolleys, Pusher dogs, Wagon.

There is a long list of components, spare parts and replacement parts that go into the design and construction of overhead transport conveyor system. From its basic structure, it has been engineered, manufactured and exported to fit a wide range of industrial applications: the overhead conveyor system is for product transport and transfer, carton handling and parts storage, surface finishing, work in progress, automotive assembly lines, buffer systems, progressive assembly, warehousing process automation, electrostatic spraying, material storage/delivery, fruits transfer, textile and apparel. We have many different models of powder coating conveyor line for sale, leave us a message for further communication.

Application of Industrial Overhead

Conveyor System

Overhead conveyors for finishing system are typically used in manufacturing facilities to move parts from one location to another. They take advantage of the generally unused vertical space above the work area. Using curved sections or lift stations, they bring parts down to operator level and back up to higher levels. Overhead conveyors can pass through production or process areas such as powder coating booth, sandblasting, cleaning, oven, liquid spray painting booths, automatic reciprocators, robotic work cells, etc. so the system also named as overhead conveyor powder coating system, dip tank conveyor, paint booth conveyor system

Assembly line overhead conveyor systems are designed for a wide range of industrial material handling applications including parts handling, overhead storage and assembly lines in manufacturing or distribution centres. In the finishing / surface treatment industry, overhead conveyors are used to move products through processes such as spray booth, dip painting, plating, e-coating, ovens, powder coating, abrasive blast room and cleaning.

Spray painting overhead conveyor systems are easy to implement in most facilities because their modular design is meant to bypass the complicated twists and turns of floor-mounted machines. They are energy efficient and use less power than most other conveyor types. When used correctly, overhead conveyor systems for painting line are an incredibly efficient, safe and reliable means of conveying which maximizes space and minimizes disruption.

For continuous and indexed transport of products, a hanging chain conveyor is often the best and most economical solution. Chain conveyors are often used as a vehicle in surface treatment, assembly, production, distribution and storage processes. Applied to different industries, it can be powder coating overhead conveyor system for paint line, overhead storage conveyor for storage of product, carton handling conveyor for empty carton box delivery to order pickers or plastic tote box delivery, automatic sheep processing conveyor for slaughter house, and hanging garment conveyor system for garment production and handling. In restaurant or hotel, the overhead conveyor system can be used as automatic robot machine to transfer food, vegetable, fruits or dishes etc.

For the more automated systems our company have a variety of conveyors ranging from power and free conveyor, brush, screw, hook, pin and clip to enable storage and transportation of the items. Get in touch with us, and let us collaborate to find your optimal solution.

Installation and Commissioning of

Overhead Conveyor System

Installation of Overhead Conveyor System

To ensure the mechanical, electrical, and structural integrity of your new system, all equipment is subjected to rigorous testing prior to commissioning. There will be no problem for overhead conveyor system installation.

Training and Documentation

Comprehensive hands-on and classroom training programs can be designed to meet your specific needs. Detailed operation/maintenance manuals and maintenance technician training provide full-time, on-site support. And our multi-disciplined engineering staff is available to provide professional expertise and support.

Maintenance and Parts

A full range of maintenance and service programs are also available to provide additional support if desired including: preventative maintenance programs; conveyor system evaluation services; and detailed conveyor operation analysis studies. Requires minimal maintenance and user training.

Contact our sales representative or parts and service team now for fast, efficient replacement parts and technical assistance.

Technical characteristics, Data & Technical Specifications of Overhead Conveyor System for Sale

|

Overhead Conveyor System for Sale |

||

|

Types |

/ |

Enclosed

track, Heavy duty, I beam Monorail, Power & Free |

|

Model |

/ |

Taiwan 5ton

7ton, X348 X458 X678 XT100 XT160 |

|

Load capacity per Pendant/per trolley |

Lbs. |

50lbs, 200lbs,

400lbs, 500lbs, 800lbs 1000lbs 1200lbs 2000lbs up to 6000lbs. per trolley |

|

Loading capacity per load bar |

kgs |

50kg, 100kg,

200kg, 300kg, 500kg, 1000kg, 1500kg, 2000kg, 3000kg, 5000kg 8000kg per

trolley |

|

Lifting weight / Max. Load weight per hanger |

T |

50kg 100kg

150kg 1ton 2ton 3ton 5ton 8ton 10ton |

|

Horizontal bends/ Vertical bends |

|

500 mm 600mm

1000mm radius at 15°/ 30°/ 45°/ 60°/ 90° |

|

Invertible |

|

Yes |

|

Load transport |

|

Synchronous

or Asynchronous movement - In a synchronous conveyor system, all loads

stop/start together and move in unison on a single track. In an asynchronous

overhead conveyor system, loads can stop/start independently and be routed

along multiple tracks running at different speeds. |

|

Chains for overhead conveyors |

|

Traction chain

and load-bearing chain, run through a closed circuit inside the carbon steel

enclosed rail or sliding track with the ability to twist along both

horizontal and vertical planes. |

|

Overhead conveyor track |

|

Single line

or two-rail lines (aerial) |

|

Assemble |

|

Easy to

assemble and disassemble and have extreme flexibility in their

layout/composition of the movement and transport circuits – based on path

length, bends and curves, and weight of the loads to be handled |

|

Overhead conveyor parts |

|

Overhead

conveyor roller chain, Motor drive unit, Sprocket, Slick rails, Vertical

drop/lifts, Overhead conveyor tracks, Incline & Decline, Bends, Vertical

elevations, Rotation devices |

|

Drive |

|

Chain driven

conveyor system, motor driven conveyor system |

|

High conveying speed |

m/min |

1~30m/min |

|

Work duty |

|

light duty or

heavy duty overhead conveyor system |

|

Power supply/ Voltage |

V |

220V 380V

400V 480V 50/60hz 3 phase |

|

Other overhead conveyor types |

|

Circular

conveyor, Accumulation overhead chain conveyor system |

|

Features |

|

Electric

control system with frequency inverter Automatic

Loading/Unloading Storage and

Retrieval Elevation Loop size

and dimension on request Light weight

due to its aluminum alloy profile tracks, it can manage loads up to 500kg/m,

the drive speed can be varied from 1 to 80m/min high speed and it has driven

curves from 5° to 180°. The system is capable of transporting up to a 25°

angle increase depending on load weight. |

|

Motor |

|

SEW motor or

China top brand |

|

Surface treatment |

|

Painted or

galvanized |

*Overhead Conveyor System parameters may be

subject to change without notice

Overhead Conveyor System Manufacturer in

China

Being an overhead conveyor system manufacturer and supplier in China, our company provide the overhead transport systems that are used to store, sort and transport items ranging from single garments to gondolas carrying 100kg of parts used in manufacturing industries.

YUANDA is an overhead conveyor company who has a long association with the materials handling industry and has a wealth of experience in taking its customers from designing a bespoke overhead conveyor system to their needs, all the way through to installation, commissioning and after sales support and service. Our company can supply and manufacture powder coating line, spray painting line, overhead rail systems, surface finishing systems and equipment on turnkey basis. We sale and export to many countries including: Saudi Arabia, Australia, European, United States, Canada, Indonesia, Mexico, Chile, Peru, UAE, Malaysia, Middle East, the United Kingdom, EU, etc. The system is based on reasonable industry design and our wealth of experience in overhead handling systems. The systems can be used in the following sectors: surface finishing, textile and apparel, metal processing, chemical and pharmaceutical, automotive and manufacture, plastics, small and flat goods, textile processing and spinning, distribution and logistics.

Overhead conveyor system layout, design drawings and installation guide manual can also be provided by our technical team. Contact us now for overhead conveyor system price.