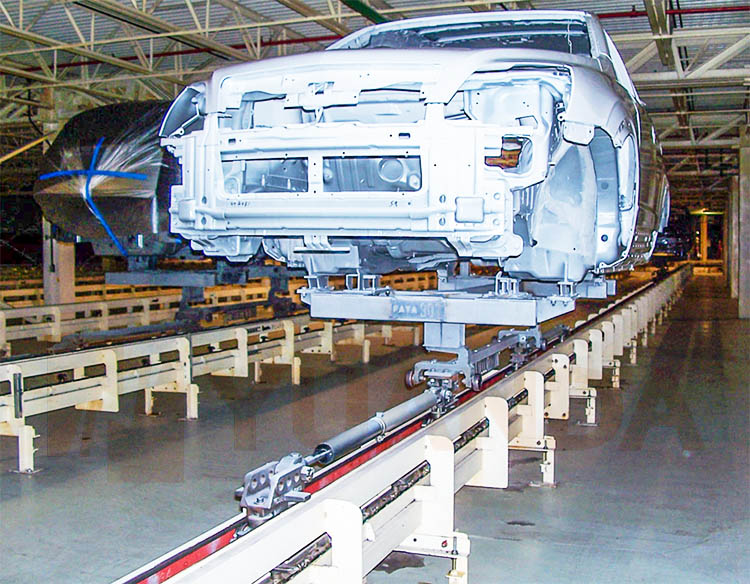

Overhead Conveyor System

Inverted Floor Mounted Chain Conveyor

Floor conveyors are used for assembly lines, paint lines and also in combination with robots. Accessible in Power & Free with accumulation, but also in a more cost-efficient monorail version.

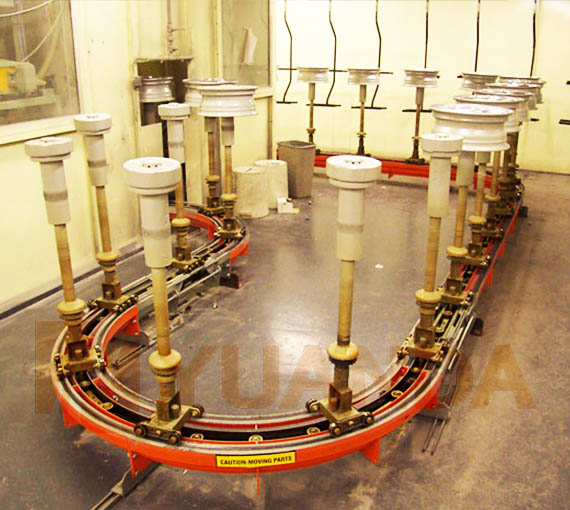

Models: Inverted P&F Conveyor

Chain carrier pitch:300mm 400mm 16”

Horizontal bends: 750 mm radius at 15°/ 30°/ 45°/ 60°/ 90°

Vertical bends: 1118 mm radius at 15°/ 30°/ 45°

Drive unit: Caterpillar drive or Worm drive

Tension unit: Draw bolt

Switches: Pneumatic / Electric

Speed: Variable speed (custom)

Power supply: AC-3Phase-220/380/400/415/440V-50/60Hz

Floor mounted conveyor manufacturer: China supplier

Floor mounted conveyor price: $30,000~$90,000

Inverted Floor Mounted Chain Conveyor

Design of Inverted Floor Mounted Chain Conveyor System

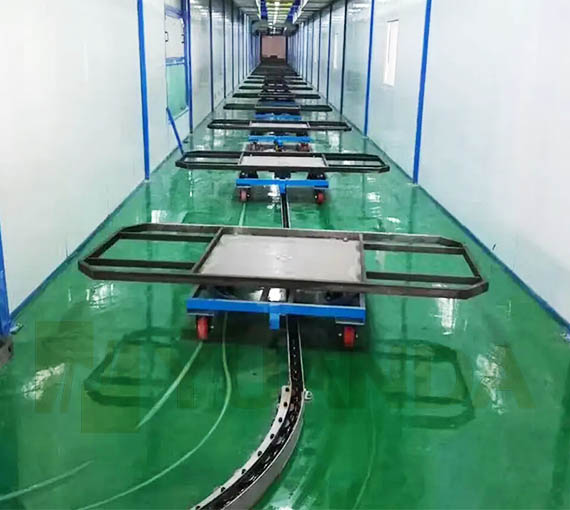

Inverted conveyors are a floor mounted conveyors on the ground that avoid costly steelworks. Ideal for plastic parts painting, our inverted floor conveyor is a modular solution for handling isolated or bound loads in form of a train.

In the case of a lubricated chain drive, your loads being over the conveyor, they are protected from any deposits of grease or dust. In the case of a friction drive inverted floor conveyor, lubrication is even not necessary, reducing maintenance.

Our company’s inverted mounted chain conveyor will be used in applications for which transported parts must remain clean of oil droplets or dirt falling from conveyor chain. Reversed conveyor has the advantage of avoiding an additional oil pan all along the handling circuit.

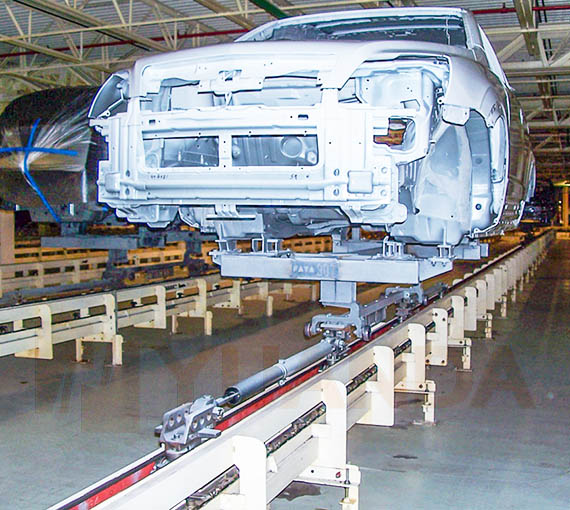

Inverted mounted overhead conveyor for paint & finishing lines, and food industry. Paint and finishing lines which include treatment surface tunnel, dryer and curing ovens will be advantageously fitted with an inverted floor mounted chain conveyor intended for high temperature applications. Benefits from its advantages, the YUANDA reversed chain conveyor may also be used as transfers conveyor

We have inverted power and free conveyor options to complement your paint equipment and finishing equipment. Our load capacities are unparalleled, and for all of our finishing line conveyors, we offer monorail floor conveyor, power and free floor conveyor solutions, automatic control, and fully installed systems for finishing conveyor applications.

From simple paint line conveyors, powder coating line to large-scale robotic systems, our expert staff will engineer a custom finishing system for your operation. To improve your workshop productivity with an inverted finishing line conveyor system from YUANDA floor mounted chain conveyor system.

Features of Inverted Floor Mounted Conveyor System

Chain carrier pitch: 150mm 200mm 250mm 300mm

Max. Temperature: 230°C / 446°F

Max. Load per Trolley: 50kg 100kg 150kg 200kg 250kg

Max. Load per Loadbar: 300kg 400kg 500kg

Standard Length, straight profile: 3.0 m / 9.8 ft

Horizontal bends: 750 mm / 29.5” radius at 15°/ 30°/ 45°/ 60°/ 90°

Vertical bends: 1118 mm / 44.0” radius at 15°/ 30°/ 45°

Drive unit: Caterpillar drive / Worm drive

Tension unit: Draw bolt

Switches: Pneumatic / Electric

Self-Supporting Structure:

Rails/Tracks: Single, two, double tracks, three tracks.

Floor track system or Hollow section enclosed C rail channel profile or Lightweight aluminum enclosed track design, aluminum profile rails for jib arm/boom

Control system: Pendant control or wireless radio remote control

Possibility to accumulate in line

No need for expensive control systems for accumulation sections due to self accumulating design

Operate at different process speeds on the same line

Low maintenance - less moving sensible parts require less attention

Full flexibility – with the same advantages as traditional Power & Free systems (switching gates, accumulation zones etc.)

Simplified plant design - compact profile design minimizes restriction in airflow in spray booths, flash offs and ovens.

Applicable industries: Inverted floor mounted chain conveyor for automobile industry, workshops, manufacturing plant, automotive industry, paint finishing and assembly lines, surface treatment industry, energy & mining.

Different Types of Inverted Floor Conveyor Systems

We offer a comprehensive range of floor conveyor systems for the surface treatment industry, finishing industry and general materials handling. Inverted floor type conveyors are available in both monorail and power and free configurations. It utilizes standard enclosed track components pre-welded at the factory, making the system simple to install, maintain and change. Inverted floor conveyor tracks offer features similar to overhead power and free conveyors with the added benefit of greater accessibility to your parts.

Floor-mounted conveyor is one of our featured inverted power & free floor conveyor systems. On top of its clean operation and seamless robotic integration, this power & free floor mounted conveyor system incorporates two rails and a trolley. This allows the system unlimited flexibility that allows stopping at key locations. For instance, with two concurrent tracks, all the painting robots in the spray booths have to do is pivot. The conveyor can then divert to multiple locations, like curing ovens.

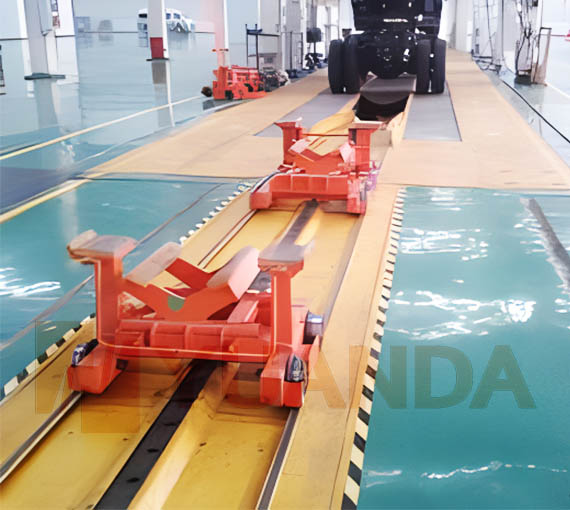

Moreover, with different structure, there can be chain conveyor floor mounted, towline floor conveyor, inverted continuous flow conveyors, enclosed track inverted floor-track type conveyors, and inverted chain conveyor. Sorted by installation method, the reversed conveyor can be designed as reversed mounted chain conveyor, inverted monorail conveyor system, in-floor chain conveyor system and floor mounted conveyor system. Grouped by varies loading capacity, the floor conveyor inverted can be made as heavy-duty floor conveyor, single line floor conveyor and inverted floor conveyor system.

There are also some other types such as single floor conveyor and double track rail inverted floor conveyor, vertical floor conveyor system, floor based inverted conveyor system and on the floor towline conveyor system.

Technical characteristics, Data & Technical Specifications of Inverted Floor Mounted Conveyor Systems

Modular and flexible, the inverted floor conveyor make it possible to meet all the implementation constraints. The characteristics are as follows:

Loop | On request |

Minimum horizontal radius | 800 mm |

Minimum vertical radius | 6000 mm |

Payload | From 20 kg to 100 kg |

Temperature | From -30°C to 150°C |

Speed | From 0.3 to 12 m/min |

Drive | By chain or friction drive |

Surface treatment | Painted or galvanized |

Options | Expansion joint, switches, automation, Load rotation units, etc. |

* Heavy duty floor mounted chain conveyor system’s specifications may be subject to change without notice.

Robust and simple, our inverted floor conveyor systems respond to the problems of paint shop lines.

Inverted Floor Mounted Chain Conveyor Application

The In-Floor Towline Conveyor is used for a number of applications. It can be used for assembly or transportation and can be integrated into a number of designs. The flexibility allows the track to be floor mounted or recessed into the floor. These energy-efficient floor chain conveyors are perfect for workshop where avoiding contamination is a paramount concern, as the inverted conveyor system components remain below the transported parts at all times.

Inverted power and free conveyors offer a great deal of flexibility in the way that products can be transported and stored. Products can be accumulated, diverted, and merged at any point on the inverted floor conveyor line. Inverted P&F conveyors can be used to handle a wide variety of products, including automotive parts, appliances, electronics, and food and beverage products.

Speak with one of our inverted chain conveyor systems integrators to determine the conveyor components and parts needed for your conveyor design. Please leave a message or email for additional details and pricing.

Advantages of Inverted Floor Mounted Conveyor System

An inverted conveyor chain system offers significant savings by reducing structural costs. The need for expensive transfer equipment is eliminated. The inverted floor mounted monorail track systems can be installed on-the-floor, flush-with-floor, or elevated to accommodate job conditions and requirements. It is unique solutions for clean and simple handling of parts through assembly line operations and finishing process equipment such as washers, dry off tunnels, paint booths, and bake ovens.

We have many different models of inverted floor mounted conveyor system for sale, contact us online now for more details.

Inverted Floor Mounted Conveyor System Manufacturer in China

YUANDA is a professional company in China offering a wide range of floor and overhead conveyors, as well as the equipment to keep your operation running smoothly. Our engineers have rich industry experience, with thousands of conveyors installed.

We perform floor and overhead conveyor work all over the world including turnkey project work, preventative maintenance, installation, commissioning, training and other technical support service. We have exported to many countries including: Saudi Arabia, Australia, European, United States, Canada, Indonesia, Mexico, Chile, Peru, UAE, Malaysia, Middle East, the United Kingdom, EU, etc.

Inverted floor mounted conveyor layout and drawings can also be provided by our technical team. Contact us now for floor mounted conveyor system price.

Related Products

Overhead hanging garment conveyors are a premium garment handling, storage, retrieval, transport, delivery, sorting conveyor system. The monorail systems are used for uniform and clothes in laundry, factory, warehouse and production line.

Automated Electrified Monorail System(EMS) is an overhead conveyor system which contain individually motorized carriers that draw energy from an aluminum track mounted bus bar and transport pallet loads throughout automotive assembly line.

Either enclosed track or I beam type, manual overhead conveyor system is a hand push-pull monorail trolley conveyor, used for spray painting, powder coating line, assembly line, carton, garment, surface treatment, automotive industry, and finishing system.

In floor mounted towline conveyor system is an inverted chain conveyor designed to pull carts along a factory ground floor, used in assembly lines, manufacturing plants, surface treatment industry, finishing, spray painting, powder coating and warehouses.