Overhead Conveyor System

Manual Overhead Conveyor

The manual monorail conveyor system is the ideal solution for overhead hand-push transport and storage applications. It provides a simple design for mechanized product handling and transfer.

Model No.:150 200 250 300 350

Load capacity: 50kg, 100kg, 200kg per hanger

Chain pitch:150mm 200mm 250mm 300mm 350mm 400mm

Maximum operating temperature: 250°C

Max. Load weight per hanger: 50kg 100kg 150kg

Horizontal bends: 500 mm 600mm radius at 15°/ 30°/ 45°/ 60°/ 90°

Vertical bends: 1000 mm radius at 15°/ 30°/ 45°

Speed: Hand push, hand pull

Manual overhead conveyor manufacturer: China supplier

Manual overhead conveyor price: $3,000~$8,000

Manual Overhead Conveyor

Design of Manual Overhead Conveyor System

YUANDA offers a variety of manual overhead conveyor systems that are ideal for batch coating applications and finishing systems with low production rates. A manual overhead conveying system will permit you to move your part, rack, or assembly from your wash booth to the dry-off batch oven, your powder coating booth and your batch cure oven. Because the trolleys are not attached to a common chain, you have the flexibility of moving the product from one station to another based on the required dwell time or your production schedule.

The overhead manual monorail system is modular making it easy to build and expand according to the customer's need. Components include drop sections for ergonomic loading, a chain transfer system, automatic loading and unloading zones, suspension system, bridge cranes, rotation units and more.

YUANDA manual overhead conveyor is designed to enhance ergonomics at loading points where heavy goods or workpieces are handled. It can also be used as a buffer zone or storage facility between different steps in the production flow. With minimal maintenance requirements and operator training, this manual overhead chain conveyor is a cost-effective solution that improves your overall efficiency.

Moving the loads is a manual operation. However, it is possible to develop automated sections using chain conveyors and pneumatic pusher systems depending on the requirements of your production processes. It’s possible to (partially) automate the manual conveyor system using various solutions like chain conveyors or pneumatic pusher systems. The manual system can be upgraded and powered in particular segments or entirely. They are available to suit a variety of industries including manufacturing, assembly line, spray painting, powder coating line, finishing system and more.

Features of Manual Overhead Conveyor System

Product name: Enclosed Track Manual Overhead Conveyor System

Model number: 150 200 250 300 350 400

Loading capacity: Taiwan 5ton 7ton 100kg 200kg 300kg

Loading weight: 500lbs 1000lbs 2000lbs

Chain model: UH-5075 WF-350 WF-400 XF400 QXT150 QXT200 QXT250 QXT300

Chain pitch(spacing): 150mm 200mm 250mm 300mm 350mm / 6” 8” 10” 12” 14”

Horizontal curves: 780mm 1000mm

Degree: 90° / 45° / 30° / 15°

Radius: 600mm 700mm 1000 mm 1200mm 1500mm

Vertical curves: 500mm 600mm 800mm

Degree (depending on work-load): 30° / 15°

Radius: 1000mm 1200mm 1500mm 2500mm

Attachments: H, U, Y shape hanger attachments

High running speed: 1~30m/min

Electric control system with frequency inverter

Product carrier: Shipping boxes or plastic totes

lightweight, compact layout, alternate routing

Trolley storage of the trolley transport systems

Integration of manual and automated sections in the same system

Track: Tubular section track, Square section track, Square tubular, Enclosed C-shaped track

Track material: I beam construction, or Hollow section enclosed C rail channel profile or Lightweight aluminum alloy enclosed track design, aluminum profile rails, aluminum tube.

A wide variety of part hooks, swivels, indexers, load bars and custom designed carriers are available to handle your product.

Using standard modular components constructed for long life, bolted track connections increase ease of enclosed track overhead conveyor installation and help minimize downtime in the event of layout modification.

Applicable industries: Manual Overhead Conveyor System for powder coating line, spray painting line, automobile industry, workshops, manufacturing plant, automotive industry, paint finishing and assembly lines, surface treatment industry, etc.

YUANDA may provide entire engineered manual conveyor systems or components only as request, if you want to buy an manual monorail overhead conveyor system, please contact us for your complete design.

Benefits & Advantages of Manual Monorail Overhead Conveyor

Manual Overhead Conveyors for Batch Powder Coating Systems

Batch Powder Coating Systems are very flexible and can process many different types of products, and a manual overhead conveyor system will be the indispensable equipment in your batch powder coating systems.

A Manual Conveyor System will allow you to efficiently move parts through powder coating line, but since the trolleys aren’t connected by a common automatic conveyor chain, each process can be moved separate from one another.

The other advantage to a Manual Conveyor System is that you can use conveyor switches and conveyor turntables, so you can change directions with your parts, or you can run multiple conveyor tracks into your oven for more efficient curing.

YUANDA Manual Monorail components are compatible with most conveyor systems. As a result, the manual monorail system can be upgraded when needed.

Since product is suspended from a monorail carrier, manual re-handling of product is kept to a minimum, reducing the chance of product damage. VMTs automatically raise and lower product, eliminating injuries related to lifting and bending. These systems realize production rehandling and manual transportation to accomplish finishing, assembly processes and storage processes with a single manual material handling system.

The manual monorail overhead conveyor system allows for simple installation, expansion or relocation according to future requirements while specific segments can be powered with power chain conveyor or automate the entire conveyor to be motor driven.

The specific series manual monorail overhead conveyor can be motorised on some sections (including switches) thanks to a side motor. For longer motorised sections, it can also receive a trolley drive chain. Stainless steel rails and trolleys can be provided.

Types of Manual Overhead Conveyor System

YUANDA's manual overhead monorail conveyor systems are designed to suit most existing working environments. They can be configured as chainless type or a low cost alternative to 'power and free' systems for certain applications where accumulation is required in ovens and buffer zones.

With different trolley track system, it can be made as manual enclosed track overhead conveyor and manual I beam overhead conveyor, which can be used to manually transport garments or multiple items on a trolley. The monorail enclosed track manual systems offer hand pushed trolleys rated for a capacity of 250 lbs. each. I-beam manual systems offer trolley capacities of 500 lbs and 2,000 lbs., depending on rail size. Sometimes it can be aluminum tube track manual overhead conveyor, which is with low force of friction and ease of movement. According to rail type, there are manual hanging conveyor with trolley, manual monorail overhead conveyor and manual overhead trolley conveyor.

Constructed of standard components, this overhead manual monorail conveyor can be added onto at any time to build a more sophisticated power monorail or power & free conveyor system. Because of its compatibility with all other overhead conveyors, conversion time is minimal and higher levels of productivity and efficiency are achieved almost immediately.

Manual overhead conveyor system is used for various overhead handling applications such as material or food transportation, painting lines, powder coating industry, assembly lines, storage, automotive, surface finishing, meat processing, textile and apparel, textile processing and spinning, distribution and logistics, general manufacturing, production lines.

We have many different models of manual overhead conveyor for sale, contact us online now for more details.

Manual Overhead Conveyor Components, Accessories and Manual Overhead Conveyor Spare Parts

Work pieces supports, carriers, load bars as well as trolleys from manual conveyors are pushed or pulled by workers, even if some areas of the handling installation may be motorized.

The manual monorail enclosed track conveyor is also used as gravity conveyors (for certain cases and for certain types of pieces) the motions of hung pieces may be facilitated by gravity effect and will reduce all or parts of people walking across the conveying installation.

A manual overhead monorail chain conveyor may include straight tracks, hand push trolley with steel bearing rollers, carrier, horizontal curves, frog switches, carrier insert section, welding jigs, carrier assembly, turntable, retractable tracks, turning devices, motorized areas, weighing stations, motorized trolley, drop section. Specific equipment can be made on request. For example: integration of special lifting systems, motorization, weighing, conveyor carriers for cooking furnace, handled with a perch, load bars for transported parts etc. Hoist travelling crane on a travelling platform can complement the manual conveying system.

The use of standard components in our product range allows for any future conveyor modification and combination with other conveyor components to be carried out easily. This way the overhead monorail track system can be combined with for example switching gates, manual or powered turning units, powered transfer units (e.g., through ovens, paint- and powder spray booths / cabins, dip-coat vessels) and vertical drop and lift sections.

Manual Overhead Conveyor Application

A Manual Push-Pull type Conveyor is the simplest and least expensive type. This allows the painter to easily hang and rotate the part to be painted and then easily move the part out of the booth for batch drying or other processes. It is easy to grow and expand this type of manual monorail chain conveyor system. You can add sections of track, floor stands, trolleys and indexing hooks at any time.

Are you facing materials handling challenges in your painting line workshop? YUANDA has the perfect solution for you – the manual overhead conveyor system, for automotive, agriculture, construction, home electronics, or general manufacturing, textile, industrial paint lines, foundry and timber factories, finishing and processing systems, assembly operations, parts transfer, textile transfer systems, storage, garment handling and more.

The manual monorail overhead chain conveyor provides a reliable and innovative way to handle your materials, and also frees up valuable floor space. Discover the flexibility and customization options offered by our modular standard program, including powered sections, vertical drop- and lift sections, and switching- and turning gates.

Manual Overhead Conveyor Manufacturer in China

YUANDA is a company supplying and installing manual overhead conveyor system, powder coating application equipment, replacement parts. With rich experience with powder coating systems, we have been involved in all stages of the process, from the original design into operation, installation, training, maintenance and aftersales service. Being a manual overhead conveyor system supplier and manufacturer in China, we have also exported to many countries including: Saudi Arabia, Australia, European, United States, Canada, Indonesia, Mexico, Chile, Peru, UAE, Malaysia, Middle East, the United Kingdom, EU, etc. YUANDA produces manual overhead conveyor and manual monorail transfer systems that are modular in design for ease of installation and modification.

Related Products

Overhead hanging garment conveyors are a premium garment handling, storage, retrieval, transport, delivery, sorting conveyor system. The monorail systems are used for uniform and clothes in laundry, factory, warehouse and production line.

Automated Electrified Monorail System(EMS) is an overhead conveyor system which contain individually motorized carriers that draw energy from an aluminum track mounted bus bar and transport pallet loads throughout automotive assembly line.

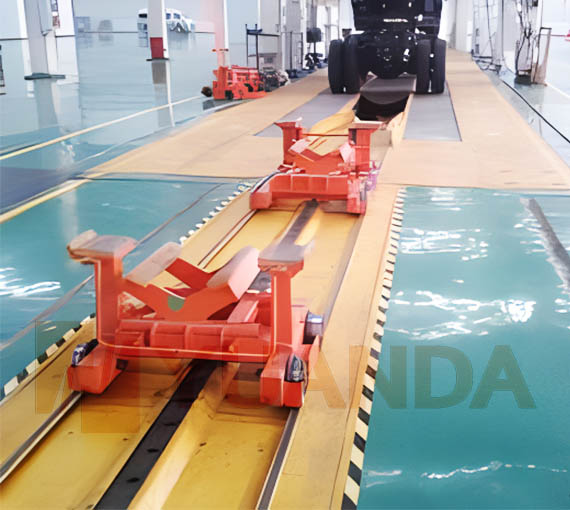

In floor mounted towline conveyor system is an inverted chain conveyor designed to pull carts along a factory ground floor, used in assembly lines, manufacturing plants, surface treatment industry, finishing, spray painting, powder coating and warehouses.