Overhead Conveyor System

Garment Hanging Conveyor

Overhead garment conveyor systems are a great solution for uniform storage and retrieval, retail garment display, inmate property storage, residential closets and so on.

Model No.:150 200 250 300 350

Load capacity: 10kg, 25kg, 50kg, 100kg per hanger

Spacing: 24mm

Material: Aluminum rail, stainless steel track

Horizontal bends: 500 mm 600mm radius at 15°/ 30°/ 45°/ 60°/ 90°

Vertical bends: 1000 mm radius at 15°/ 30°/ 45°

Drive unit: Electric motor or Manual

Power and free: Available

Speed: Variable speed as standard (or custom)

Power supply: AC-3Phase-220/380/400/415/440V-50/60Hz

Garment hanging conveyor manufacturer: China supplier

Garment hanging conveyor price: $5,000~$40,000

Garment Hanging Conveyor

Design of Garment Hanging Conveyor Line

It would be challenging to keep the workflow steady on a busy garment conveyor line. Whether you operate a busy dry cleaner, a hotel, a hospital, a garment factory or another business that needs to move garments along a production line, a top of the line overhead garment conveyor will help you maximize your space and boost the productivity of your operations.

The YUANDA clothing on hanger storage conveyors are manufactured in many different sizes and configurations. No matter what your application is, we have a garment conveyor that will handle your application. Our storage GOH conveyors are commonly used in e-commerce fulfillment, garment on hanger (GOH) storage, coat checks, uniform storage and retrieval, dry cleaners, laundry, hospitality, retail displays and prison & correctional facilities property storage. They come in many sizes and shapes. We design the garment handling overhead conveyors for simple toggle controls and also with full touchscreen data capture systems for GOH Assembly, and employee ID applications. When you reach out to YUANDA you will get full support with design assistance, from project cost to full CAD support documentation. If you are checking coats and packages on your garment overhead conveyor then you need a tag system. We make high quality, reusable coat check and bag check tags too.

These hanging garment conveyor systems are engineered to optimize space utilization and streamline operations, contributing to increased productivity and reduced labor costs. We utilize high-quality materials and cutting-edge manufacturing processes to ensure the durability and longevity of the hanging garment conveyor. Additionally, our company provides customized solutions tailored to the specific needs of the clients, enhancing operational efficiency and workflow.

Features of Enclosed Track Overhead Garment Conveyor

Product name: Overhead Garment Hanging Conveyor System

Model number: GOH

Quiet, clean, smooth

Attachments: H, U, Y shape hanger attachments, ladder type hanger.

High running speed: 1~30m/min

Electric control system with frequency inverter.

Integration a garment conveyor with face recognition gain access and RFID gain access

Storage racks: Available in 3, 5 and 10 slot options.

Rail: V rail

Track: Tubular section track, Aluminum tube, Lightweight aluminum alloy enclosed track design, Aluminum profile rails, aluminium slick rail

Single track, two tracks, multiple tracks garment hanging conveyor

One tier, two tier garment hanging conveyor

Elevation change: 90° / 45° / 30° / 15°

Trolley roller: Y type trolley

Chrome plated hanger bracket link & trolley, frame-black.

Yokes: Stamped zinc plated, two 1-3/8” diameter nylon treaded load bearing wheeled carrier with a load capacity of 30lbs. Single yoke or dual yoke.

Trolley wheels: Plastic wheels or nylon wheels.

Single plane or double plane or multiplane garment conveyor

Single tier or double tier.

Suitable for heavy loads or large elevation changes and changes of direction on secondary levels in “L”, “U” and “T” layouts.

Drive system: Conventional belt drive, Chain drive system, Chainless drive, Gear motor drive systems, which are ideal for low, medium, and high-power transmission.

Controls: Hand control, Foot control, Digital control with remote positioning system, Wireless tablet control

The garments can be fully tracked and sorted using barcode or RFID.

RFID tags access

Fast storage and retrieval of garments

Multi-level conveyor storage area

Bolt together track with no welding required makes installation and modifications easy and cost effective.

GOH (Garments On Hangers) can be ceiling supported or floor supported garment conveyor.

Applicable industries: Hanging garment overhead conveyor for industrial laundries and dry cleaners, correctional institution, textile, warehousing, retail and residential garment handling solutions, etc.

Benefits & Advantages of Garment Conveyor

An Automated Garment Conveyor offers a wide range of benefits for your business. YUANDA has several clothing warehouse storage solutions for all sorts of items, all based on rotating systems, automated storage and retrieval systems or conveyors. They share some advantages, for example, garment storage factory conveyors reduce the likelihood of errors by automating the picking or dispatch process; They can handle and pick single and/or multiple SKUs; The monorail clothes hanging conveyor can find an item belonging to a specific order in a large set of mixed items thanks to advanced management software that tracks the loaded items, quickly identifying and positioning each item; The overhead conveyor system for uniform & clothes optimise the routing of the system to reduce order picking time. Whether it’s a loop structure or a system made up of several lines or levels, items can be extracted or picked simultaneously from different locations

We offer an extensive range of fully automated computerised, simple, fast and reliable control systems that order, sort and organise garments. The garment monorail systems manage the whole handling process in an independent manner from the deposit of dirty clothes to the pickup of clean ones. Automated garment delivery systems for the handling, storage and management of hanging garments in dry cleaners.

Our industrial garment handling solutions helps to regulate workflow, increase productivity and enhance your customer service. It also helps keep track of uniform movement entering or leaving the system, monitoring suppliers and optimizing garment supply. And its modular design provides for an easily expandable system as the business grows.

The automated uniform management system for the automatic storage, conveying and distribution of work uniforms, garments, overalls, white coats, scrubs, etc. You can easily manage and dispense staff uniforms and workwear with our uniform distribution systems.

Bagging equipment has become a staple and essential piece of equipment for all garment handling professionals. This garment equipment is available on request.

The automated uniform management conveyors can make substantial differences in hospitals, hotels, factories, airlines, industrial laundries, workshops, warehouses,

Technical Data & Technical Specifications of Hanging Garment Overhead Conveyor System

Model | Unit | GOH conveyor |

Hanging NO. | Nos | 300-5000 |

Dimension(LxWxH ) | mm | As per layout |

Voltage | V | 110/220V/380V three phase power supply |

Power | kw | 0.75/1.5/3kw |

Motor drive | mm | Continuous duty 1/6 hp |

Loading Weight | Kg | 50kg |

Load | Garments on hangers | |

Features | Lubrication free rail Suspension points every 4' Quiet, clean, lubrication free operation Easy installation. Ready to suspend Continuous operation Transfer to continuous accumulation rail is automatic |

*Heavy duty enclosed track garment hanging overhead conveyor specifications and configuration may be subject to change without notice.

Different Types of Garment Overhead Conveyor Line

YUANDA develops garment material handling, storage and sorting solutions for our clients. Either chain or chainless type, our variety of garment conveyors covers the range of requirements in today’s sophisticated garment handling industry.

Our overhead conveyor system for garment, also known as garment handling ski lifts, come in two formats, speed rail for trolley systems and the more prevalent slick rail or box rail garment elevators. Both types of garment conveyor come fully fitted with guards, aluminum tube track, motor gearboxes and chains, or chainless type. Our higher capacity double-tier garment conveyors include the double tier, the single tier and the floor-to-ceiling double tier. In addition, we also feature a standard floor to ceiling garment conveyor.

Running on different tracks, the overhead hanging garment conveyor line can be designed as enclosed track conveyor and monorail system. The enclosed track garment conveyor system can accommodate elevation changes up to a 45 degree angle. V rail, garment monorail conveyor system can be suspended from the ceiling to free up costly workshop space, garments are stored on hand push trolleys that travel on V-Rail lines. With different driving mechanism, it can be electric motorized or manual garment conveyor. YUANDA garment rails are the most efficient manual method for storing and retrieving large volumes of garments on hangers (GOH).

In total, our modular design hanging garment conveyors including the following: The V-dip garment conveyor combining space saving and efficient garment retrieval; the coat check or package conveyor provides superlative modern coat checking; the assembly garment conveyor provides fast assembly operation; the slide garment conveyor provides slot-free handling and moving of garments. and many other types such as automated uniform conveyor, garment rails, garment sorting conveyor, powered trolley rails garment, laundry monorail, overhead garment storage conveyor, garment automatic order assembly system, slick rail garment conveyors, garment transport conveyor, rolling clothing racks, uniform hanging conveyor, garment power tube pin conveyor, garment on hanger transport conveyors(GOH), carousel pick module. All of these garment monorail overhead conveyor systems are used for garment storage, dry cleaning, uniform rental, laundries, garment distribution, linen supplies and garment manufacturing.

We have many different models of overhead garment hanging conveyor for sale, contact us online now for more details.

Hanging Garment Overhead Conveyor Components, Accessories and Overhead Garment Hanging Conveyor Spare Parts

YUANDA garment overhead conveyor lines are an optimal solution for your garment storage and transfer needs. Our conveyors can be used to store high volumes of hanging garments in small spaces and retrieve garments quickly and efficiently.

YUANDA design, manufacture and install bespoke Commercial Garment Handling Conveyors, Racking and Rail systems. These garment handling equipment’s range includes: Garment conveyor and elevator systems, Garment handling ski lift, Metal hanging garment racks, racking and storage, Garment rail systems – Slick Rail, Glide Rail, Overhead Garment unpacking and packing tables, including mobile tables.

Automation control system: Items are located and delivered via the shortest route. This automated storage and retrieval system can be programmed to operate automatically when the user swipes their ID tag or enters their tag number. It can also be operated by an attendant through barcode scan or manual key pad entry. While most conveyors offer a manual left/right switch, our garment overhead conveyor systems can include an electronic controller that automates the entire process, making your operations more productive. Electronic controllers can also be connected to your POS system or database for facilitated inventory control and a better overview of your workflow.

YUANDA may provide entire engineered clothing storage conveyors for garments on hangers or components only as request, if you want to buy a garment hanging conveyor system, please contact us for your complete design.

Garment Overhead Conveyor Application

Clothes conveyors are the best system solution for the automation of enterprises, exhibitions, garment manufacturing, garment production line, dry cleaners, laundries, and other businesses.

The compact modular design of the garment conveyor allows for a variety of configurations to suit your specific needs. Our hanging clothes conveyor systems are excellent for uniform storage and retrieval, inmate property storage, retail garment display, residential closets, specialty garment storage and retrieval, automated coat check and more. The enclosed track garment conveyor systems can be configured to handle almost any hanging garment and can be installed in virtually any space requirement. This automatic garment storage and retrieval system can also be used to handle other hanging items such as printing dies, cartons, artwork for museums and other items that require cataloged storage and on-demand retrieval. They have wide applications in laundry room, dry cleaning shops, garments factories, garment manufacturing plant for textile transfer systems, storage, garment handling and sorting.

Enclosed Track Overhead Garment Hanging Conveyor Manufacturer in China

YUANDA company is a prominent manufacturer and supplier of garment hanging conveyor systems in China. Specializing in advanced conveyor technology, our company offer a comprehensive range of solutions designed to meet the unique requirements of the textile and garment industry. Our monorail overhead conveyor systems for garment are made with robust construction, efficiency, and innovative design, ensuring seamless movement and handling of garments within factories and warehouses. We have exported to many countries including: Saudi Arabia, Australia, European, United States, Canada, Indonesia, Mexico, Chile, Peru, UAE, Malaysia, Middle East, the United Kingdom, EU, etc., catering to the diverse needs of the international market.

Overhead garment hanging conveyor’s layout and drawings can also be provided by our technical team. Contact an YUANDA representative to discuss your conveyor needs.

Related Products

Automated Electrified Monorail System(EMS) is an overhead conveyor system which contain individually motorized carriers that draw energy from an aluminum track mounted bus bar and transport pallet loads throughout automotive assembly line.

Either enclosed track or I beam type, manual overhead conveyor system is a hand push-pull monorail trolley conveyor, used for spray painting, powder coating line, assembly line, carton, garment, surface treatment, automotive industry, and finishing system.

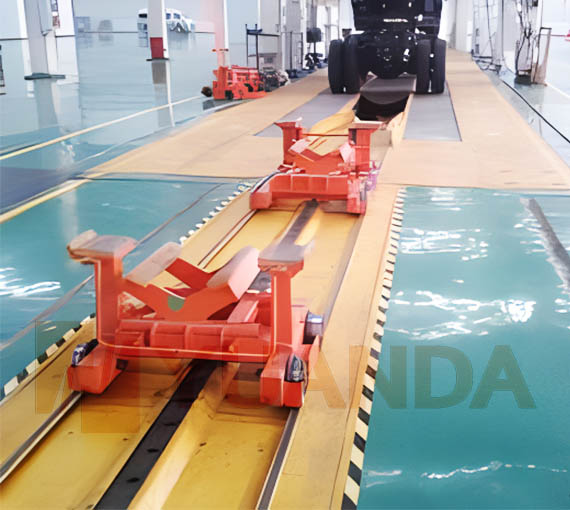

In floor mounted towline conveyor system is an inverted chain conveyor designed to pull carts along a factory ground floor, used in assembly lines, manufacturing plants, surface treatment industry, finishing, spray painting, powder coating and warehouses.