Overhead Conveyor System

I Beam Overhead Conveyor

Overhead I-beam hanging conveyor system comes in three track sizes: 3” 4” 6” or namely X348 X458 X678. Because of its versatility, I-beam trolley conveyor applications include workshop, paint finishing lines and automotive assembly plants. They are sometimes called I beam monorail trolley track systems in factories.

Model No.: X348 X458 X678

Load capacity: 120 kg, 250kg and 450kg per hanger.

Chain pitch:300mm 400mm 16”

Max. Temperature: 250°C

Max. Load per Trolley: 250kg

Max. Load per Loadbar: 2000kg

Horizontal bends: 500 mm 600mm radius at 15°/ 30°/ 45°/ 60°/ 90°

Vertical bends: 1000 mm radius at 15°/ 30°/ 45°

Drive unit: Caterpillar drive or sprocket

Tension unit: Yes

Speed: Variable speed (custom)

Power supply: AC-3Phase-220/380/400/415/440V-50/60Hz

I beam overhead conveyor manufacturer: China supplier

I beam overhead conveyor price: $30,000~$90,000

I Beam Overhead Conveyor

Design of I Beam Overhead Conveyor Line

I-beam overhead conveyor systems are open-track conveyors where the forged rivetless chain rides on an I-shaped metal beam that is suspended horizontally from the ceiling. Items are transported on pendants or trolleys that hang down from the I-beam and are propelled by the chain. These heavy-duty I beam chain conveyors are designed to accommodate loads up to 678 lbs. per pendant.

China YUANDA I-beam conveyor is comprised of industry standard, high quality components. With load bearing track components consisting of wear resistant 1045 high carbon steel, our I-beam trolley conveyor systems provide years of trouble-free operation with only minimal maintenance. I-Beam track can be twisted and turned, horizontally and vertically, in a limitless combination of designs. Fully exposed and rivetless chain allows for easy inspection and lubrication. Trolleys may be open faced allowing for spray lubrication or sealed with grease fittings. Inline torque arm Caterpillar drives unit are fitted with sensors for overload protection. Floating take-up frames are often similarly outfitted with travel limits to warn and protect against over-stretched chain.

Available in 3 basic sizes and types: 3”, 4” and 6” I-Beam monorail conveyors are the most commonly used overhead conveyors in the industry. I-beam overhead conveyors allow easier product handling in a variety of applications, including assembly, finishing, storage, powder coating, spray painting and more.

Features of Overhead I Beam Trolley Conveyor System

I-Beam Track: Available in 3”, 4” and 6” conveyor track heights

Heavy duty drop forged chain and trolleys

Confirm to industry standards so components are easily interchangeable with existing old conveyor line in your workshop

Drop forged, rivetless chain is highly flexible and requires no tools for assembly

Open track and chain design, all components are exposed and visible

Track length: 20’ long as standard

Part number/Model: X348 X458 X678 XT80 XT100 XT160

Trolley size: 3” 4” 6” X-348 X-458 X-678

Loading capacity: 100kg 150kg 200kg 250kg 300kg 400kg 500kg 1000kg 1 2 3 ton

Single trolley capacity: 200lbs 400lbs 1200lbs

Loading capacity per load bar: 400lbs 800lbs 2400lbs

Rivetless chain size: 3” 4” 6” X-348 X-458 X-678

Chain pitch: 300mm 400mm 500mm 600mm /12” 14” 15” 16”

I beam size: 3” 4” 6” 8# 10# 12# 16#

Roller trolley spacing: 16” 18” 24” 30” 32” 36”

Vertical curve radius: 5 6 8 10 12 15 ft.

Horizontal turn radius: 18” 24” 36”

X type rivetless chain

I-beam rollerbank turn, 30° 45° 90° 180°

I-beam traction wheel turn 45° 90° 180°

Attachments: "H", "I", & "B" attachments

Control system: control cabinet

Heavy duty capacity

A variety of trolley assemblies and carrier attachments are available

Applicable industries: I beam overhead conveyor for powder coating line, spray painting line, automobile industry, workshops, manufacturing plant, automotive industry, paint finishing and assembly lines, surface treatment industry, etc.

Benefits & Advantages of I Beam Overhead Conveyor System

The I-Beam overhead conveyor track manufactured of high-quality carbon steel has outstanding wear and load capacities. Its durable welded construction is ideal for long-term use. The I beam trolley track easily incorporates turns and elevation changes that skirt obstacles. The drop-forged trolleys are designed for heavy use with smooth running operation. The chain is easily assembled or adjusted without the need for tools. The trolleys incorporate rivetless construction. The trolleys and loadbars are available in capacities up to 400 lbs each with 3" track, up to 800 lbs each for 4" track, and up to 2,400 lbs. each for 6” track. With three capacities available, there is a suitable overhead I-beam conveyor for selection from lighter weight material handling to heavy industrial assembly lines.

I-Beam conveyor is an overhead hanging style of conveyor allowing minimal footprint. These systems free up valuable floor space for more valued-added operations by organizing product flow and efficiently utilizing available space overhead. All steel construction allows for coveted high load capacity systems. These overhead I-Beam monorail conveyor systems eliminate needless production rehandling and manual transportation by accomplishing finishing, assembly processes and/or storage processes with a single material handling system. Due to I-Beam’s simplicity, the conveyor systems are rugged, reliable and require little maintenance.

The typical applications of I-Beam overhead monorail conveyor systems are for industrial assembly lines, automotive, food and beverage, household appliances, office equipment, pharmaceuticals, warehousing process automation, finishing systems and material storage/delivery.

We have many different models of I beam overhead conveyor for sale, contact us online now for more details.

Technical Data & Technical Specifications of Overhead I Beam Conveyor Systems

Type | Single Trolley Capacity | Capacity with Load Bar | Hanging Points |

X-348 | 200 Lb | 400 Lb | Configurable on 6″ Spacings |

X-458 | 400 Lb | 800 Lb | Configurable on 8″ Spacings |

X-678 | 1200 Lb | 2400 Lb | Configurable on 12″ Spacings |

Types of I Beam Overhead Conveyor

I-beam conveyor comes in three track sizes, each with a different load capacity. 3" high track has a 200 pounds capacity per trolley, this model conveyor is called X348 I beam overhead conveyor; 4" track of the X458 I beam overhead conveyor has a 400 pounds capacity; and 6" track of the X678 I beam overhead conveyor has an impressive 1,200 pounds capacity. A load bar hung from two trolleys offers twice the capacity of a single trolley, so a load bar for 6" track can handle 2,400 pounds.

Overhead I-beam monorail systems are best suited for applications with heavier product loads or excessive chain pull. There are several factors that determine which size is best suited for your specific application. X-348 I beam overhead chain conveyor system and X-458 I beam overhead conveyor system are the more common sizes. Heavy duty X-678 I beam overhead chain conveyor system is for more heavy duty applications, used widely in the surface finishing and powder coating industry. All three sizes are built around drop forged rivetless conveyor chain with open or sealed trolleys on predetermined centers. If you want to buy the I beam overhead conveyor, please contact YUANDA company for recommendation or technical assistance.

I Beam Overhead Conveyor Components, Accessories and I Beam Overhead Conveyor Spare Parts

Suspend monorail track from floor-mounted support steel beams or ceiling attachments. Some systems may require a combination of the two. Our I-beam chain conveyor is comprised of industry standard, high quality components. Heavy duty trolleys or rollers connected by a forged rivetless chain ride on an I-beam monorail. I-Beam track can be twisted and turned, horizontally and vertically. Each trolley has an attachment point from which a load carrier can be suspended. A variable speed drive unit grabs and moves the I beam overhead conveyor chain and thus the trolleys connected to it; suspended loads move synchronously, stopping and starting together and moving at the same speed. Fully exposed and rivetless chain and trollies allows for easy inspection and lubrication. The high-horsepower Caterpillar drive unit provides powerful power output for the conveyor line.

YUANDA company’s 3″, 4″ and 6″ I-Beam monorail conveyors are amongst the most commonly used overhead conveyors in the powder coating industry. Wheel turns can be from 18″ to 30″ radius, roller turns of 18″ to 60″ radius. In-line drives or sprocket turn drives are capable of pulling thousands of feet of chain with variable speeds. And a full line of I-Beam trolley assemblies and attachments can be selected to meet your specific application needs.

Other available components and spare parts are: Caterpillar drive chains, I beam monorail track, I beam rail system, X348 X458 X678 drop forged rivetless chain, X348 trolley roller, X458 trolley roller, X678 trolley roller, expansion joints, trolley pairs, 3″ 4″ 6″ conveyor trolley, load bars, bends, horizontal curves (Rollerbank or Wheel Turns), vertical curves, Take-Up unit, automatic chain lubricator, tension units, electrical control system and so on.

I Beam Overhead Conveyor Application

Common applications for I-Beam type overhead conveyors:

I Beam Overhead Conveyor for Assembly Lines

I-beam monorail's high capacities and great durability make it one of the most commonly used conveyors for industrial assembly lines. Equip it with carriers that present loads at an ergonomic height for convenient access to every side of the work-in-progress. Adjust the variable speed controls of the I-beam conveyor in an automotive assembly line to move parts at a speed that is suitable to your rate of production.

I Beam Overhead Conveyor for Spray Painting & Finishing Lines

Automate the transport of parts in a variety of finishing processes where manual handling would be too dangerous for workers or damaging to the product. Use corrosion-resistant and heat-resistant I-beam overhead chain conveyor to move items through chemical washes and curing ovens. I beam monorail overhead conveyor can incorporate turns and elevation changes, declines and inclines for effective dip lines, and is also beneficial in spray booths where every side of the product is accessible. So I-beam conveyor is widely used in wet spraying of heavy components.

With additional functions, including accumulation and storage of work-in-progress, it is power and free I beam overhead conveyor. For more typical applications, the overhead I beam trolley conveyor can be for powder coating lines, paint lines, surface treatment, live storage of products, work in progress, automotive assembly lines, paint finishing systems, buffer systems, progressive assembly, textile transfer systems, and so on.

Contact us for more information about China I-beam trolley monorail and other overhead hook conveyor solutions.

I Beam Overhead Conveyor Manufacturer in China

YUANDA company is a professional I beam overhead conveyor manufacturer and supplier focus on improving productivity and efficiency for manufacturing products in various industries and warehousing and distribution centers around the world. Due to its unique design and excellent characteristics, the overhead I-Beam conveyor can offer elevated efficiency to production lines. I-BEAM trolley systems have been proven to supply the cheapest “cost per lb. of capacity” of overhead conveyors. We are capable of producing I-Beam monorail trolley conveyors with improved components for cost effective conveying in varies applications. Due to our expertise in this field, our high-level workers and reliable engineers provide high-quality I-Beam monorail chain conveyors manufactured according to customer requirements. We have exported to many countries including: Saudi Arabia, Australia, European, United States, Canada, Indonesia, Mexico, Chile, Peru, UAE, Malaysia, Middle East, the United Kingdom, EU, etc.

I beam overhead conveyor’s layout and drawings can also be provided by our technical team. Contact us now for I beam overhead conveyor line price.

Related Products

Overhead hanging garment conveyors are a premium garment handling, storage, retrieval, transport, delivery, sorting conveyor system. The monorail systems are used for uniform and clothes in laundry, factory, warehouse and production line.

Automated Electrified Monorail System(EMS) is an overhead conveyor system which contain individually motorized carriers that draw energy from an aluminum track mounted bus bar and transport pallet loads throughout automotive assembly line.

Either enclosed track or I beam type, manual overhead conveyor system is a hand push-pull monorail trolley conveyor, used for spray painting, powder coating line, assembly line, carton, garment, surface treatment, automotive industry, and finishing system.

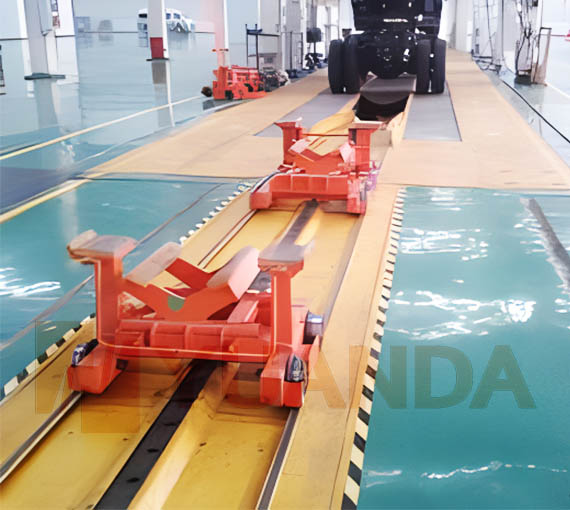

In floor mounted towline conveyor system is an inverted chain conveyor designed to pull carts along a factory ground floor, used in assembly lines, manufacturing plants, surface treatment industry, finishing, spray painting, powder coating and warehouses.