Overhead Conveyor System

Overhead Monorail Chain Conveyor

The motor driven overhead monorail chain conveyor is a robust, efficient and hard-wearing monorail overhead conveyor system, suitable for use in a wide variety of applications.

Model No.:150 200 250 300 350

Load capacity: 50kg, 100kg, 200kg per hanger

Chain pitch:150mm 200mm 250mm 300mm 350mm 400mm

Max. Temperature: 250°C

Max. Load weight per hanger: 50kg 100kg 150kg

Horizontal bends: 500 mm 600mm radius at 15°/ 30°/ 45°/ 60°/ 90°

Vertical bends: 1000 mm radius at 15°/ 30°/ 45°

Drive unit: Caterpillar drive or sprocket

Speed: Variable speed as standard (or custom)

Power supply: AC-3Phase-220/380/400/415/440V-50/60Hz

Overhead monorail chain conveyor manufacturer: China supplier

Overhead monorail chain conveyor price: $5,000~$40,000

Overhead Monorail Chain Conveyor

Design of Overhead Monorail Chain Conveyor

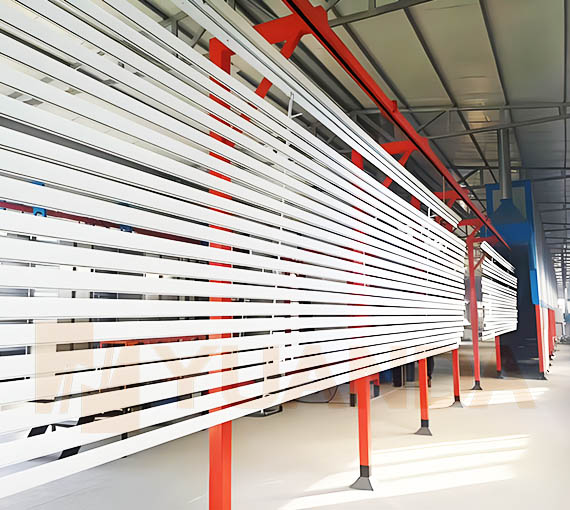

The YUANDA overhead monorail chain conveyor, also known as the monorail overhead conveyor system, operates in numerous industrial production lines at the workshops, often in challenging environments.

The hanging monorail overhead chain conveyor forms a closed loop. From small circuit to long distance routing including level differences, our company’s overhead hanging chain conveyor will bring you many advantages. Work pieces or carried loads hang on conveyor chain directly or by intermediate supports as load bars, carriers, rotation devices, hooks, links, etc. The overhead conveyor chains with fixed carriers is powered within the standard profile: an enclosed C-shaped track, either aluminum track or steel tube, driven by one or several units with fixed or variable speed. Chains have bearing and guiding rollers thus ensuring friction-less motion in horizontal and vertical curves. Curves are arched sections that require no extra holding rolling or idler wheel. Thanks to its sturdiness and design, the roller chain will convey work pieces without effort throughout long and sinuous conveyor circuit.

Depending of total load carried, conveyor circuit length, etc. one or several traction groups will drive the conveyor chain continuously or in a step by step moving in an overhead drag chain conveyor. Adjusted by a frequency inverter, chain running speed is adjustable and it remains characteristic to be clarified for each monorail overhead conveyor.

In an overhead chain monorail system, loading or unloading robots may be included inside the handling installation as well as automatic vertical dipping stations and equipment like gripper system easing hoisting works. Our company’s technical team will answer any need you may have with innovative solutions.

The paint booth overhead monorail chain conveyors are often used for spray paint line, powder coating line & finishing lines with surface treatment tunnel, blasting booth, drying or curing ovens, paint booth. Monorail overhead chain conveyors are suitable for handling a wide variety of products in many industry sectors, such as: automotive, carton, surface finishing, meat processing, textile and apparel, automotive and manufacture, textile processing and spinning, distribution and logistics, general manufacturing, production line.

Features of Overhead Monorail Chain Conveyor

Model number: 150 200 206 240 250 300 350 400 X348 X458 X678

Loading capacity: Taiwan 5ton 7ton

Chain model: UH-5075 WF-350 WF-400 XF400 QXT150 QXT200 QXT250 QXT300

Chain pitch(spacing): 150mm 200mm 250mm 300mm 350mm / 6” 8” 10” 12” 14”

Horizontal curves: 780mm 1000mm

Radius: 600mm 700mm 1000 mm 1200mm 1500mm

Vertical curves: 500mm 600mm 800mm

Degree (depending on work-load): 90° / 45° / 30° / 15°

Radius: 1000mm 1200mm 1500mm 2500mm

Attachments: H, U, Y shape hanger attachments

High running speed: 1~30m/min

Electric control system with frequency inverter

Adjustable clutch protection protects each drive unit and conveyor chain against overload.

Components: Take-Up units, inspection section, lubricator, motor

Product carrier: Shipping boxes or plastic totes

Trolley storage of the trolley transport systems: OCS overhead conveyor solutions increase storage density in the Intralogistics industry

Quite, clean, low noise, fast speed

Compact layout, alternate routing

Integration of manual and automated sections in the same system

Fully Automated Conveyor is used for both E-commerce orders (B2B/B2C) and replenishment

READING TECHNOLOGY: BCR & RFID

Efficient order picking system, efficient material flow solutions

Design of software based on years’ experience

Track: Tubular section track, Square section track, Square tubular, Enclosed C-shaped track

Track material: I beam construction, or Hollow section enclosed C rail channel profile or Lightweight aluminum alloy enclosed track design, aluminum profile rails, aluminum tube.

A wide variety of part hooks, swivels, indexers, load bars and custom designed carriers are available to handle your product.

Using standard modular components constructed for long life, bolted track connections increase ease of overhead monorail chain conveyor installation and help minimize downtime in the event of layout modification.

Loading and unloading robots, manipulators, elevators, can be added to an overhead chain monorail conveyor system.

Suspended tray conveyors should be disassembled from the conveyor, or be indexed.

Applicable industries: Enclosed track monorail overhead chain conveyor for powder coating line, spray painting line, automobile industry, workshops, manufacturing plant, paint shop, automotive industry, paint finishing system and assembly lines, surface treatment industry, process automation, food and beverage, household appliances, office equipment, comber lap delivery, extrusion finishing, pharmaceuticals, retail, textile and warehousing, etc.

YUANDA may provide entire overhead monorail chain conveyor systems or components only as request, if you want to buy an overhead monorail chain conveyor, please contact us for your complete design.

Technical Data & Technical Specifications of Overhead Monorail Chain Conveyor

Chain pitch: 150mm 200mm

Max. Temperature: 260°C / 500°F

Max. Load: 150 kg

Max. Load per hanger plate: 100kg 200kg

Standard Length, straight profile: 3.0m / 9.8ft

3” Enclosed Track

Trolley bearings: Closed and greased for low maintenance | Horizontal bends: 3” Chain: 305 mm / 12” radius at 15°/ 30°/ 45°/ 60°/ 90°/160 4” Chain: 610 mm / 24” radius at 15°/ 30°/ 45°/ 60°/ 90°/180

Vertical bends: 3” Chain: 305 mm / 12” radius at 15°/ 30°/ 45°/ 60°/ 90°/160 4” Chain: 610 mm / 24” radius at 15°/ 30°/ 45°/ 60°/ 90°/180

Special dimensions on request.

Drive unit: Caterpillar drive

Tension unit: Spring-loaded, Draw bolt |

* Fast speed spray painting line overhead monorail chain conveyor specifications may be subject to change without notice.

The powder coating overhead monorail chain conveyor can receive rotation systems for parts carried in an automatic or manual paint booth, or in a blasting machine. The rotation can be done either through a sprocket wheel (continuous rotation) or by rotation blocks: 45°, 90°, etc.

Different Types of Overhead Monorail Chain Conveyor

Monorail overhead hanging chain conveyors mainly come in two types: I-beam monorail overhead conveyor, and enclosed track monorail overhead conveyor. In details, it can be I-beam trolley track conveyor system(including X348 overhead monorail chain conveyor, X458 overhead monorail chain conveyor, X678 overhead monorail chain conveyor), aluminum round tube enclosed track overhead conveyor, square tubular enclosed track overhead conveyor. It is designed as per clients' requirements and can be upgraded to a power and free monorail overhead conveyor system utilizing all the existing components, for transfer, storage and accumulation application.

With different driving mechanism, there are hand-pushed trolley monorail conveyors, manual overhead monorail conveyors, motor driven monorail overhead conveyors and friction driven monorail overhead conveyors. Overhead monorail chain conveyor can be installed in a floor mounted reversed position, which is called inverted mounted chain conveyor. Made by different raw material, there can be aluminum alloy overhead monorail conveyor and stainless steel monorail overhead chain conveyor. For some special model, it can be made as chainless monorail overhead conveyor, aluminum monorail overhead conveyor.

With many different designs, the monorail overhead chain conveyors are suitable for many industry sectors, e.g. automotive, surface finishing, powder coating industry, meat processing, Cast Mold Delivery, Progressive Assembly, Aerospace Refinishing, Textile and Apparel, Automotive and Manufacture, Textile processing and Spinning, Distribution and Logistics, general manufacturing plant, workshop production line.

Monorail Overhead Chain Conveyor Components, Accessories and Monorail Overhead Chain Conveyor Spare Parts

Using standard modular components constructed for long life, the spray painting overhead chain conveyors solve a variety of manufacturing problems. From simple, in-line finishing systems to complex storage and retrieval systems, the spray painting line monorail overhead conveyor system is an efficient and economical solution. The overhead monorail chain conveyor components and spare parts are: heavy duty universal link conveyor chain, monorail track, aluminum tube, horizontal curves, vertical curves, spinner, swivel hook, oven expansion joints, automatic chain lubricator, suspension fittings, worm drive unit, motor, tension unit, Pendants, Welding Jig, expansion unit, inspection unit, lubrication unit, Take-up assembly, chain sprocket, etc. Benefits from its modular design, the overhead monorail chain conveyors are used for spray painting line, powder coating line, material storage/delivery, paint finishing systems, progressive assembly, trash conveyors, empty carton return, robotic interface and other manufacturing plant.

In most cases, the monorail is delivered after disassembled. Rails, curves, and various components of the conveyor can be easily assembled one onto the other with bolts, according to provided assembly drawing, which makes the assembly very simple.

Monorail Overhead Chain Conveyor Applications

The powder coating line monorail overhead conveyor are designed to fit a variety additional applications including: surface treatment industry, automotive industry, food industry, bicycle manufacturers, workshops, logistics and e-commerce industry, intralogistics industry, omnichannel retail, carton delivery system, distribution and sorting, industrial paint lines, foundry and timber factories, finishing and processing systems, assembly operations, parts transfer, Sliver Can Delivery, Fiber Delivery, textile transfer systems, buffer storage, garment handling, displays and entertainment in shopping malls and super market. It is ideal for transfer and transport materials across a wide range of industries such as domestic appliances, wood furniture, automotive parts, fruits, cartons, sports and leisure goods and garment handling. In short, monorail overhead transport systems can be used to store, sort and transport items.

We have many different models of overhead monorail chain conveyor system for sale, contact us online now for more details. We are able to provide fully customized solutions to meet our clients’ needs.

Monorail Overhead Chain Conveyor Manufacturer in China

YUANDA Company’s monorail overhead conveyors provides both whole turnkey conveyor systems and components to meet your specific needs. Being a monorail overhead conveyor manufacturer and supplier in China, we offer the complete design, fabrication, software control systems and overhead conveyor installation service. We have exported to many countries including: Saudi Arabia, Australia, European, United States, Canada, Indonesia, Mexico, Chile, Peru, UAE, Malaysia, Middle East, the United Kingdom, EU, etc. We provide competitive pricing, fast reply on quotes and delivery of materials.

Monorail overhead chain conveyor’s layout and drawings can also be provided by our technical team. Contact us now for your monorail overhead conveyor system design.

Related Products

Overhead hanging garment conveyors are a premium garment handling, storage, retrieval, transport, delivery, sorting conveyor system. The monorail systems are used for uniform and clothes in laundry, factory, warehouse and production line.

Automated Electrified Monorail System(EMS) is an overhead conveyor system which contain individually motorized carriers that draw energy from an aluminum track mounted bus bar and transport pallet loads throughout automotive assembly line.

Either enclosed track or I beam type, manual overhead conveyor system is a hand push-pull monorail trolley conveyor, used for spray painting, powder coating line, assembly line, carton, garment, surface treatment, automotive industry, and finishing system.

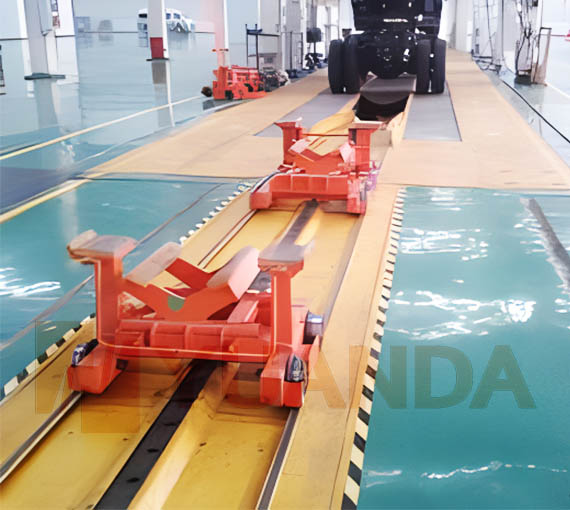

In floor mounted towline conveyor system is an inverted chain conveyor designed to pull carts along a factory ground floor, used in assembly lines, manufacturing plants, surface treatment industry, finishing, spray painting, powder coating and warehouses.