Overhead Conveyor System

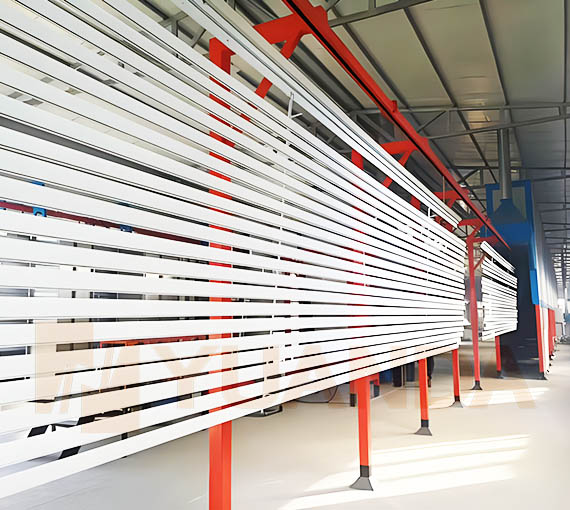

Overhead Conveyor System for Spray Painting Line

Common types of spray painting conveyors include: overhead enclosed track, I-beam, manual, power and free, tow lines, belt and roller conveyors for overhead hang conveyor lines, onfloor and infloor tow lines and flat lines.

Model No.:X348 X458 X678 150 200 250 300 350

Load capacity: 50kg, 100kg, 200kg per hanger

Chain pitch:150mm 200mm 250mm 300mm 350mm 400mm

Max. Temperature: 250°C

Max. Load weight per hanger: 50kg 100kg 150kg

Horizontal bends: 500 mm 600mm radius at 15°/ 30°/ 45°/ 60°/ 90°

Vertical bends: 1000 mm radius at 15°/ 30°/ 45°

Drive unit: Caterpillar drive or sprocket

Speed: Variable speed as standard (or custom)

Power supply: AC-3Phase-220/380/400/415/440V-50/60Hz

Overhead conveyor system for spray painting line manufacturer: China supplier

Overhead conveyor system for spray painting line price: $5,000~$40,000

Overhead Conveyor System for Spray Painting Line

Design of Monorail Overhead Conveyor System for Spray Painting Line

A painting conveyor is a type of overhead conveyor system that is used to transport products through a painting process. Spray painting conveyor system can be used to apply a variety of coatings, including paints, powders, and sealants. This overhead conveyor spray painting system has an enclosed track design which helps prevent contaminants from reaching the chain and bearing surfaces. Or it can also be I beam monorail conveyor type, with X348 X458 X678 trolley chain running on I beam track. The I beam overhead conveyor system for spray painting line, is used for heavy duty applications. And it also can be power and free overhead conveyor system, for spray painting line where products must be transported to different process areas and where accumulation is required in ovens and buffer zones. This P&F conveyor supports asynchronous movement.

Spray painting monorail overhead conveyor systems are typically used in manufacturing and assembly lines to paint products such as automotive parts, aluminum parts, appliances, electronics, metals, plastics, wood, propane tank, gas cylinder, doors, windows, food and beverage products. Spray paint booth conveyor systems can also be used in other industries, such as woodworking and metalworking. Generally speaking, the spray painting overhead conveyor system is widely used in many industry sectors: automotive, surface finishing system, assembly line, spray painting, powder coating line, general manufacture plant and production line.

Wet spray paint operations may involve spray booths with automatic spray guns, dip tank, reciprocator, or robotics for precision spray painting and even manual spray systems.

Features of Overhead Conveyor System for Spray Painting Line

Product name: Spray Painting Line Overhead Conveyor System

Model number: Single Line, 150 200 206 240 250 300 350 400

Part number/Model: X348 X458 X678 XT80 XT100 XT160

Loading capacity: Taiwan 5ton 7ton 100kg 150kg 200kg 250kg 300kg 400kg 500kg 1000kg 1 2 3 ton

Chain model: X348 X458 X678 UH-5075 WF-350 WF-400 XF400 QXT150 QXT200 QXT250 QXT300

Chain pitch(spacing): 150mm 200mm 250mm 300mm 350mm / 6” 8” 10” 12” 14”

Horizontal curves and Vertical curves: 600mm 700mm 1000 mm 1200mm 1500mm 2500mm radius

Degree: 90° / 45° / 30° / 15°

Attachments: H, U, Y shape hanger attachments, "H", "I", & "B" attachments

Hanger: various types for choice, Y type, C type, U type, Cross Type, Disc Type, etc.

Electric control system with frequency inverter

Compact layout, alternate routing

Fully Automated

Integration of manual and automated sections in the same system

Design of software based on years’ experience

Handle and transport products through powder coating booth, powder curing and drying oven

Track: Tubular section track, Square section track, Square tubular, Enclosed C-shaped track

Track material: I beam construction, or Hollow section enclosed C rail channel profile.

Components and Spare Parts: motor, lubrication unit, inspection unit, expansion unit, spinner, swivel hook. A wide variety of part hooks, swivels, indexers, load bars and custom designed chain carriers are available to handle your product.

Requires minimal maintenance and user training.

Common suspension versions include:

• One-point turning device, with or without fixation.

• Load bar attached to 2 or 4 chain carriers.

variable frequency drive (VFD) can added to the electric motor

Using standard modular components constructed for long life, bolted track connections increase ease of enclosed track overhead conveyor installation and help minimize downtime in the event of layout modification.

Applicable industries: Enclosed track overhead conveyor system for spray painting line, finish line, automobile industry, workshops, manufacturing plant, automotive industry, paint finishing and assembly lines, surface treatment industry, etc.

YUANDA may provide entire spray painting overhead chain conveyor system or components only as request, if you want to buy an spray painting line overhead conveyor system, please contact us for your complete design.

Benefits & Advantages of Spray Painting Line Overhead Conveyor System

Overhead chain conveyor for spray painting line can be adapted to accommodate various layouts and configurations, including complex curves and turns.

Benefits from variable speed control, spray painting track system often allow for adjustable speeds to accommodate different parts and coatings.

Integration with Automation: Spray painting conveyor line can be seamlessly integrated with automated powder coating systems, robots, and other automation technologies.

Offer hooks and carriers suitable to hold or hang the particular items being powder coated.

Technical Data & Technical Specifications of Spray Painting Line Overhead Conveyor System

Chain pitch: 150mm 200mm 250mm 300mm / 3”, 4”, 6” Max. Temperature: 260°C / 500°F

Max. Load: 150kg 200kg 300kg 500kg 1ton 2ton

Max. Load per hanger plate: 100kg 400kg 600kg 1ton 2ton 3ton 5ton

Standard Length, straight profile: 3.0m / 9.8ft

3” Enclosed Track, Dual track system

Trolley bearings: Closed and greased for low maintenance | Horizontal bends: 3” Chain: 305 mm / 12” radius at 15°/ 30°/ 45°/ 60°/ 90°/160 4” Chain: 610 mm / 24” radius at 15°/ 30°/ 45°/ 60°/ 90°/180

Vertical bends: 3” Chain: 305 mm / 12” radius at 15°/ 30°/ 45°/ 60°/ 90°/160 4” Chain: 610 mm / 24” radius at 15°/ 30°/ 45°/ 60°/ 90°/180

Special dimensions on request.

Drive unit: Caterpillar drive

Take-up assembly: Spring-loaded, Draw bolt

|

* Heavy Duty Spray Painting Line Overhead Conveyor System specifications may be subject to change without notice.

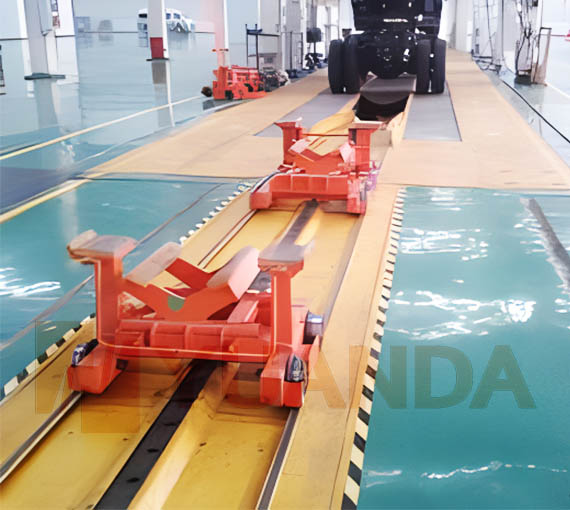

Different Types of Spray Painting Line Overhead Conveyor System

There are a variety of different types of painting conveyor system available, each with its own advantages and disadvantages. Some of the most common types of monorail painting conveyors include: I beam overhead conveyor system for spray painting line (3” 4” 6”), including X348 X458 X678 three types; enclosed track overhead conveyor system for spray painting line and power and free overhead conveyor system. With different installation methods, it can be designed as overhead monorail conveyor system for spray painting line, in which the steel structural support is added to hold the conveyor system in place as products run along the track, or roof ceiling mounted; and inverted floor conveyor, which is ground floor mounted. With different driving mechanism, there are manual overhead conveyor, motor driven automated overhead conveyor and electric powered overhead conveyor system for spray painting line. There are some other common types such as spray painting conveyor line for sale, paint line conveyor, overhead trolley conveyor for spray painting, etc. All the types can also be for power coating line’s finishing treatment process. The best type of painting conveyor for a particular application will depend on the type of products being painted, the type of coating being applied, and the desired production rate. Our company provides liquid spray painting overhead conveyor systems for dip coating, electroplating, powder coating, wet spray, dip line, E-coat paint and finishing applications.

We have different models of overhead conveyor system spray painting line for sale, contact us now for more details.

Spray Painting Line Overhead Conveyor System Components, Accessories and Spare Parts

Monorail overhead conveyor systems are often used in the paint and finishing line as it allows the finishing applications to be done without any hindrance. The monorail overhead conveyor system for spray painting line is resistant to harsh chemicals used in washing, degreasing, phosphating, outgassing and sandblasting processes. and can withstand high temperature during curing. Overhead paint lines are custom made based on customer requirements for production and floor space. To know more about the overhead hanging conveyor system for spray painting line, here is list of key components: heavy duty universal link conveyor chain, carts, carriers, loading & unloading equipment, power rotators, Caterpillar drive chains, I beam monorail track, X348 X458 X678 drop forged rivetless chain, X348 trolley roller, X458 trolley roller, X678 trolley roller, power track, P&F track, oven expansion joints, trolley pairs, 3″ 4″ 6″ conveyor trolley, pendants, load bars, bends, chain sprocket, welding jig, suspension fittings, horizontal curves (Rollerbank or Wheel Turns), vertical curves, Take-Up unit, automatic chain lubricator, tension units, inspection section, control system, etc.

Spray painting chain conveyors are a type of overhead conveyor system that utilizes a continuous chain to transport workpieces through powder coating lines. They offer several advantages over other conveyor systems, making them a popular choice for high-volume production and challenging environments.

Applications of Spray Painting Overhead Conveyor Systems

Whether you use a wet spray or a powder coat system for painting, the overhead monorail conveyor spray painting system is an effective form of conveyance. The enclosed track design means no moving parts are exposed and lubrication is completely confined within the track.

Spray painting monorail conveyor system can also be used in multi-stage finishing systems. The 450° F maximum temperature makes it suitable for most drying or curing ovens. It is ideal for use in complete systems with cleaning, coating, painting, curing or any combination without costly intermediate manual handling or transfer. Generally, the powder coating or liquid spray painting conveyor system is designed for surface treatment industry, automotive industry, bicycle manufacturers, workshops, industrial paint lines, foundry and timber factories, finishing and processing systems, assembly operations, parts transfer, storage, transfer and transport. Overhead monorail conveyor systems for spray painting offer a highly effective and efficient solution for transporting workpieces through powder coating lines and spray painting line. Their versatility, space optimization, and ability to integrate with automation make them a valuable asset for high-volume production and complex layouts.

Spray Painting Overhead Conveyor Line Manufacturer in China

YUANDA is a China supplier and manufacturer for overhead conveyor system for spray painting line. Our company offers custom designs of overhead conveyor and complementary finishing equipment. We also offer installation, maintenance, training service on a turnkey basis. We have exported to many countries including: Saudi Arabia, Australia, European, United States, Canada, Indonesia, Mexico, Chile, Peru, UAE, Malaysia, Middle East, the United Kingdom, EU, etc. Contact us today to discover all the options and benefits available for your specific painting application.

Related Products

Overhead hanging garment conveyors are a premium garment handling, storage, retrieval, transport, delivery, sorting conveyor system. The monorail systems are used for uniform and clothes in laundry, factory, warehouse and production line.

Automated Electrified Monorail System(EMS) is an overhead conveyor system which contain individually motorized carriers that draw energy from an aluminum track mounted bus bar and transport pallet loads throughout automotive assembly line.

Either enclosed track or I beam type, manual overhead conveyor system is a hand push-pull monorail trolley conveyor, used for spray painting, powder coating line, assembly line, carton, garment, surface treatment, automotive industry, and finishing system.

In floor mounted towline conveyor system is an inverted chain conveyor designed to pull carts along a factory ground floor, used in assembly lines, manufacturing plants, surface treatment industry, finishing, spray painting, powder coating and warehouses.