Overhead Conveyor System

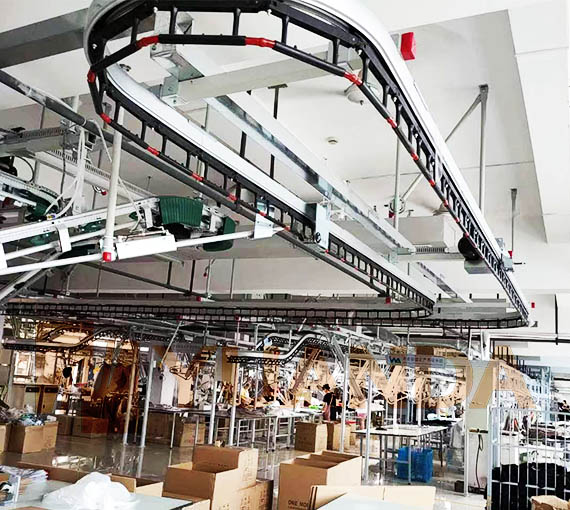

Enclosed Track Overhead Conveyor System

Light duty enclosed track overhead conveyor system utilizes an enclosed steel track which guides the chains and trolleys and protects them from direct contamination.

Model No.:150 200 250 300 350 5T 7T

Load capacity: 50kg, 100kg, 200kg per hanger

Chain pitch:150mm 200mm 250mm 300mm 350mm 400mm

Max. Temperature: 250°C

Max. Load weight per hanger: 50kg 100kg 150kg

Horizontal bends: 500 mm 600mm radius at 15°/ 30°/ 45°/ 60°/ 90°

Vertical bends: 1000 mm radius at 15°/ 30°/ 45°

Drive unit: Caterpillar drive or sprocket

Tension unit: Yes

Speed: Variable speed as standard (or custom)

Power supply: AC-3Phase-220/380/400/415/440V-50/60Hz

Enclosed track overhead conveyor manufacturer: China supplier

Enclosed track overhead conveyor price: $5,000~$40,000

Enclosed Track Overhead Conveyor System

Design of Enclosed Track Overhead Conveyor System

An overhead chain conveyor is often the best and most economical solution for the continuous and indexed transport of products. Our enclosed track overhead chain conveyors have a compact, bolted track design for easy assembly without welding, allowing for a modular system with highest quality moveable components inside the track. An enclosed track monorail chain conveyor typically consists of a track with a drive chain running through it. The drive chain is enclosed in either a round or box tube, with items transported on pendant hangers or trolleys that hang down from the conveyor chain across the shop floor.

The YUANDA Enclosed Square Track Conveyors are well suited for light duty conveyor applications such as paint lines, garment handling, trash removal, carton handling, assembly lines and parts storage. They increase productivity by making use of available overhead space and improving material flow.

The enclosed style track helps prevent contamination of the track interior and chain, reducing cleaning and maintenance costs. The inverted style floor mounted conveyors can also help keep dust, grease and other debris away from your product and work area, which is especially important on paint lines requiring a cleaner environment. This type is called inverted monorail enclosed track conveyor, or inverted floor mounted chain conveyor.

The YUANDA Enclosed Track Conveyors are designed to handle 75 lbs. (34 kg) per pendant and can withstand temperatures up to 450°F with proper lubrication. Horizontal curves come in 24” (standard), 36”, 48” and vertical curves 24” (standard) and 36”. Medium duty and heavy-duty options are available to suit a variety of needs including manufacturing, assembly line, spray painting, powder coating line, finishing system and more.

Features of Enclosed Track Overhead Conveyor Line

Product name: Enclosed Track Overhead Conveyor System

Model number: 150 200 206 240 250 300 350 400

Loading capacity: Taiwan 5ton 7ton

Chain model: UH-5075 WF-350 WF-400 XF400 QXT150 QXT200 QXT250 QXT300

Chain pitch(spacing): 150mm 200mm 250mm 300mm 350mm / 6” 8” 10” 12” 14”

Horizontal curves: 780mm 1000mm

Degree: 90° / 45° / 30° / 15°

Radius: 600mm 700mm 1000 mm 1200mm 1500mm

Vertical curves: 500mm 600mm 800mm

Degree (depending on work-load): 30° / 15°

Radius: 1000mm 1200mm 1500mm 2500mm

Attachments: H, U, Y shape hanger attachments

High running speed: 1~30m/min

Electric control system with frequency inverter

Product carrier: Shipping boxes or plastic totes

Trolley storage of the trolley transport systems: OCS overhead conveyor solutions increase storage density in the Intralogistics industry

Compact layout, alternate routing

Fully Automated

Integration of manual and automated sections in the same system

Conveyor is used for both E-commerce orders (B2B/B2C) and replenishment

READING TECHNOLOGY: BCR & RFID

Efficient order picking system, efficient material flow solutions

Design of software based on years’ experience

Track: Tubular section track, Square section track, Square tubular, Enclosed C-shaped track

Track material: I beam construction, or Hollow section enclosed C rail channel profile or Lightweight aluminum alloy enclosed track design, aluminum profile rails, aluminum tube.

A wide variety of part hooks, swivels, indexers, load bars and custom designed carriers are available to handle your product.

Using standard modular components constructed for long life, bolted track connections increase ease of enclosed track overhead conveyor installation and help minimize downtime in the event of layout modification.

Applicable industries: Enclosed track overhead conveyor for powder coating line, spray painting line, automobile industry, workshops, manufacturing plant, automotive industry, paint finishing and assembly lines, surface treatment industry, etc.

YUANDA may provide entire engineered monorail enclosed track overhead conveyor systems or components only as request, if you want to buy an enclosed track overhead conveyor system, please contact us for your complete design.

Technical Data & Technical Specifications of Enclosed Track Overhead Chain Conveyor System

Chain pitch: 76.2, 150mm 101.6 mm / 3”, 4” 8” Max. Temperature: 260°C / 500°F Max. Load: 150 kg/m | 100.8 lbs/ft Max. Load per hanger plate: 113 kg / 249 lbs Standard Length, straight profile: 3.0m / 9.8ft 3” Enclosed Track Trolley bearings: Closed and greased for low maintenance | Horizontal bends: 3” Chain: 305 mm / 12” radius at 15°/ 30°/ 45°/ 60°/ 90°/160 4” Chain: 610 mm / 24” radius at 15°/ 30°/ 45°/ 60°/ 90°/180 Vertical bends: 3” Chain: 305 mm / 12” radius at 15°/ 30°/ 45°/ 60°/ 90°/160 4” Chain: 610 mm / 24” radius at 15°/ 30°/ 45°/ 60°/ 90°/180 Special dimensions on request. Drive unit: Caterpillar drive Tension unit: Spring-loaded, Draw bolt |

*Heavy duty enclosed track overhead conveyor specifications may be subject to change without notice.

Different Types of Enclosed Track Overhead Conveyor

A range of monorail overhead chain conveyors suitable for handling a wide variety of products in many industry sectors, e.g. automotive and manufacture, surface finishing, powder coating industry, meat processing, textile and apparel, auto parts, small and flat goods, textile processing and spinning, distribution and logistics, general manufacturing, workshop production line. Then overhead monorail enclosed track chain conveyor come in two types: Round tube enclosed track conveyor, Square tubular enclosed track conveyor. They are designed to meet manufacturers' changing needs and can be upgraded to a power and free system utilizing all the existing components, which is called power and free enclosed track overhead conveyor.

With different driving mechanism, there are motor driven overhead conveyors and friction driven enclosed track overhead conveyors. Sorted by installation methods, it can be designed as enclosed track overhead monorail conveyor, which is installed on support steel structure or roof ceiling mounted, and inverted floor mounted enclosed track chain conveyor. Made by different raw material, there can be aluminum alloy overhead conveyor and stainless steel overhead chain conveyor. With different loading weight, it can be divided as enclosed track overhead conveyor 5T (Taiwan) and enclosed track overhead conveyor 7T (Taiwan).

We have different models of enclosed track overhead conveyor system for sale, contact us now for more details.

Enclosed Track Overhead Conveyor Components, Accessories and Enclosed Track Overhead Conveyor Spare Parts

Simple in nature, the monorail overhead conveyor system is modular and expandable from hand push conveyor systems to powered overhead conveyors to power and free systems. The enclosed track overhead monorail chain conveyor consists of a full range of components that can achieve nearly any conveying task.

Available in various lengths and also in stainless steel, the overhead monorail track system is the starting point for a motorized conveyor. The enclosed track is mounting to the floor or roof supported steel support structures. It is either welded together or bolted together. Horizontal curves enable to track to turn left and right, while vertical curves enable the track to go up and down. Universal link conveyor chain runs through the track. It’s unique configuration with side guide rollers enables very low friction and extremely long life. Chain is inserted into the track via a special piece of track which has a hinged opening which can open and close. Trolley attachments are added at the required spacing where the conveyor will carry its load. Some have spinners to allow the parts to rotate. A simple overhead hook conveyor system is easy to build with the available attachments. The overhead monorail enclosed chain conveyor system is motorized by adding a drive unit. The Caterpillar drive unit includes an electric motor, gearbox (with various ratios available depending on the required feet per minute chain speed) and the necessary chain drive system to pull the main chain through the track. If for any reason the conveyor chain should ever jam, the electric motor drive can be programmed (via PLC or a relay) to automatically shut down the conveyor once the force limit is reached. It’s common to add a variable frequency drive (VFD) to the electric motor. Finally, a take up is added. The purpose of the take up is to tension the chain, so it does not bunch up and so it runs smoothly in the track.

Other available components and spare parts are: heavy duty universal link conveyor chain, monorail track, spinner, swivel hook, oven expansion joints, automatic chain lubricator, suspension fittings, worm drive unit, tension unit, expansion unit, inspection unit, lubrication unit, Take-up assembly, chain sprocket, etc.

Enclosed Track Overhead Conveyor Application

Square Track Section is a light-duty motor-driven conveyor, with a chain that moves within a rail system. At fixed intervals, product “hangers” are installed to transport the desired product along the conveyor. The horizontal and vertical bends can be offered at various radii depending on the pitch lengths and the product being carried. The monorail enclosed track overhead chain conveyor is used for transport applications across a wide variety of industries such as domestic appliances, automotive parts, sports and leisure goods and garment handling.

In details, the monorail enclosed track overhead conveyor provides solutions for the automotive industry, namely for the production of trucks, engines, wheels and other specialized machinery parts, where parts need to be routed to multiple spray booths or the smooth transportation of products is required. And our conveyors are widely used across the surface treatment industry, carrying the product through flash-off zones, spray cabins, powder coating units, washing areas, pretreatment areas, drying and curing ovens. The monorail enclosed track overhead conveyor systems can also be specially designed as food-grade chain conveyors that are used in the food industry for food processing applications, which ensures a non-toxic, non-corrosive and high-speed, smooth-running operating environment. Our hanging conveyors can be used for garment handling, to store high volumes of hanging garments with high density and retrieve.

Besides, we also provide custom solutions to clients in a variety of different industries ranging from bicycle manufacturers, textile, logistics and e-commerce industry, intralogistics industry, omnichannel retail, carton delivery system, distribution and sorting, industrial paint lines, to foundry and timber factories, finishing and processing systems, assembly operations, parts transfer, textile transfer systems, storage, garment handling, displays and entertainment in shopping malls and super market. In short, monorail overhead transport systems can be used to store, sort and transport items. We are able to provide fully customized solutions to meet our clients’ needs.

Enclosed Track Overhead Conveyor Manufacturer in China

YUANDA Company’s finishing systems provides both whole turnkey conveyor systems and components to meet your specific needs. Being a professional enclosed track overhead conveyor manufacturer and supplier in China, we offer overhead monorail, overhead power and free conveyor, floor mounted systems, and custom conveyor solutions, we also offer the complete design, fabrication, control systems and overhead conveyor installation service. We have exported to many countries including: Saudi Arabia, Australia, European, United States, Canada, Indonesia, Mexico, Chile, Peru, UAE, Malaysia, Middle East, the United Kingdom, EU, etc. We provide competitive pricing, fast reply on quotes and delivery of materials.

Enclosed track overhead conveyor’s layout and drawings can also be provided by our technical team. Contact an YUANDA representative to discuss your conveyor needs.

Related Products

Overhead hanging garment conveyors are a premium garment handling, storage, retrieval, transport, delivery, sorting conveyor system. The monorail systems are used for uniform and clothes in laundry, factory, warehouse and production line.

Automated Electrified Monorail System(EMS) is an overhead conveyor system which contain individually motorized carriers that draw energy from an aluminum track mounted bus bar and transport pallet loads throughout automotive assembly line.

Either enclosed track or I beam type, manual overhead conveyor system is a hand push-pull monorail trolley conveyor, used for spray painting, powder coating line, assembly line, carton, garment, surface treatment, automotive industry, and finishing system.

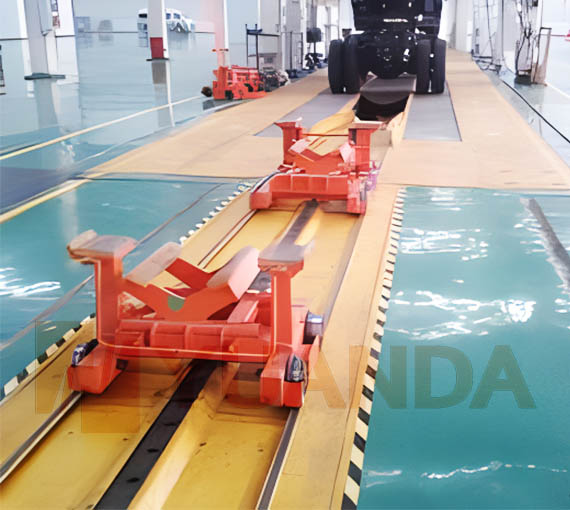

In floor mounted towline conveyor system is an inverted chain conveyor designed to pull carts along a factory ground floor, used in assembly lines, manufacturing plants, surface treatment industry, finishing, spray painting, powder coating and warehouses.