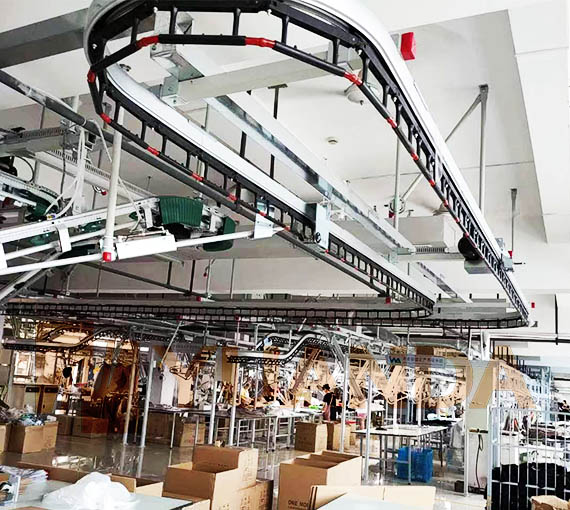

Overhead Conveyor System

Monorail Overhead Conveyor System

The hanging monorail overhead conveyor system has advanced features of high degree of automation, which is the ideal solution for e-commerce industry and logistic system.

Model No.:150 200 250 300 350

Load capacity: 50kg, 100kg, 200kg per hanger

Chain pitch:150mm 200mm 250mm 300mm 350mm 400mm

Max. Temperature: 250°C

Max. Load weight per hanger: 50kg 100kg 150kg

Horizontal bends: 500 mm 600mm radius at 15°/ 30°/ 45°/ 60°/ 90°

Vertical bends: 1000 mm radius at 15°/ 30°/ 45°

Drive unit: Caterpillar drive or sprocket

Speed: Variable speed as standard (or custom)

Power supply: AC-3Phase-220/380/400/415/440V-50/60Hz

Monorail overhead conveyor system manufacturer: China supplier

Monorail overhead conveyor system price: $5,000~$40,000

Monorail Overhead Conveyor System

Design of Monorail Overhead Conveyor System

The single line overhead conveyor features a standard aluminum profile, complemented by horizontal and vertical curves. A motorized chain with fixed carriers is powered within the standard profile, driven by one or several units with fixed or variable speed. Items are conveyed suspended directly from the carriers or within specially designed suspension devices/work jigs/ladders (customized configurations).

Utilizing tested, high-quality components enhances the functionality and lifetime of the monorail overhead conveyor system. Easy-to-combine, modular standard components offer a wide range of customized solutions. The overhead monorail track system has advanced features of high degree of automation and flexible application, which is the ideal solution for e-commerce industry and logistic system, covering a wide range of product groups – from automotive to apparel and other applications. It is complemented by automated workstations for ergonomic loading and unloading. Overhead monorail conveyor system guides the products intelligently and efficiently through all processes. Integrated reading processes automate the recording and tracking of products from goods receipt, through the dynamic warehouse, the sorting process and to goods issue. The monorail overhead conveyor system is widely used in many industry sectors: automotive, paint shop, surface finishing, meat processing, textile and apparel, manufacture plant, distribution and logistics, general manufacturing plant, production line and more.

Features of Monorail Overhead Conveyor System

Product name: Enclosed Track Monorail Overhead Conveyor System

Model number: Single Line, 150 200 206 240 250 300 350 400

Loading capacity: Taiwan 5ton 7ton

Chain model: UH-5075 WF-350 WF-400 XF400 QXT150 QXT200 QXT250 QXT300

Chain pitch(spacing): 150mm 200mm 250mm 300mm 350mm / 6” 8” 10” 12” 14”

Horizontal curves: 780mm 1000mm

Degree: 90° / 45° / 30° / 15°

Radius: 600mm 700mm 1000 mm 1200mm 1500mm

Vertical curves: 500mm 600mm 800mm

Degree (depending on work-load): 30° / 15°

Radius: 1000mm 1200mm 1500mm 2500mm

Noiseless, silent

Attachments: H, U, Y shape hanger attachments, jigs, net mesh type Ladder carrier

A wide variety of part hooks, swivels, indexers, load bars and custom designed carriers are available to handle your product.

High running speed: 1~30m/min

Electric control system with frequency inverter

Adjustable clutch protection protects each drive unit and conveyor chain against overload

Components: Take-Up units, inspection section, lubricator, motor

Requires minimal maintenance and user training.

Common suspension versions include:

• One-point turning device, with or without fixation.

• Load bar attached to 2 or 4 chain carriers.

Variable frequency drive (VFD) can added to the electric motor

Product carrier: Shipping boxes or plastic totes

Low noise, fast speed

Trolley storage of the trolley transport systems: OCS overhead conveyor solutions increase storage density in the Intralogistics industry

Compact layout, alternate routing

Fully Automated. Orders are put together or returns are collected quickly

Integration of manual and automated sections in the same system

Conveyor is used for both E-commerce orders (B2B/B2C) and replenishment

Reading technology: BCR & RFID

Efficient order picking system, efficient material flow solutions

Design of software based on years’ experience

Track: Tubular section track, Square section track, Square tubular, Enclosed C-shaped track

Track material: I beam construction, or Hollow section enclosed C rail channel profile or Lightweight aluminum alloy enclosed track design, aluminum profile rails, aluminum tube.

Using standard modular components constructed for long life, bolted track connections increase ease of enclosed track monorail overhead conveyor system installation and help minimize downtime in the event of layout modification.

Applicable industries: Monorail Overhead Conveyor System for powder coating line, spray painting line, automobile industry, workshops, manufacturing plant, automotive industry, paint finishing and assembly lines, surface treatment industry, etc.

YUANDA may provide entire Engineered Systems or Components only as request, if you want to buy a Monorail Overhead Conveyor System, please contact us for your complete design.

Benefits & Advantages of Monorail Overhead Conveyor System

Simplifies Installation and Maintenance

Overhead monorail chain conveyor is constructed of standard, modular components that guarantee easy installation, modification and maintenance. Standard components also guarantee quick accessibility through local stocking distributors.

Increases Throughput

With its 6" pitch, the monorail overhead chain conveyor provides 33% more hanging points than competitive products. The result is a reduction in the size of corresponding process equipment.

Maximizes Floor Space

The monorail overhead conveyor's standard 1'-6"R horizontal and 2'-0"R vertical curves can make tight changes in direction and elevation, freeing up valuable floor space for other assembly and storage operations.

Reduces Product Damage

The monorail conveyor system can transport product anywhere, in return, product handling and damage are kept to a minimum.

We have many different models of monorail overhead conveyor system for sale, contact us online now for more details.

Technical Data & Technical Specifications of Monorail Overhead Conveyor System

Chain pitch: 76.2, 150mm 101.6 mm / 3”, 4”, 8” Max. Temperature: 260°C / 500°F

Max. Load: 150 kg/m | 100.8 lbs/ft

Max. Load per hanger plate: 113 kg / 249 lbs

Standard Length, straight profile: 3.0m / 9.8ft

3” Enclosed Track, Aluminum tube rail

Trolley bearings: Closed and greased for low maintenance | Horizontal bends: 3” Chain: 305 mm / 12” radius at 15°/ 30°/ 45°/ 60°/ 90°/160 4” Chain: 610 mm / 24” radius at 15°/ 30°/ 45°/ 60°/ 90°/180

Vertical bends: 3” Chain: 305 mm / 12” radius at 15°/ 30°/ 45°/ 60°/ 90°/160 4” Chain: 610 mm / 24” radius at 15°/ 30°/ 45°/ 60°/ 90°/180

Special dimensions on request

Drive unit: Caterpillar drive, friction drive

Tension unit: Spring-loaded, Draw bolt

Take-Up Units, Inspection Section, Lubricator

|

*Light duty Monorail Overhead Conveyor System specifications may be subject to change without notice.

Different Types of Monorail Overhead Conveyor System

When considering different types of monorail overhead conveyor systems, the space above the floor can easily be utilized. Most powder coating plants have similar requests to maximize space, speed up efficiency and automate the process. And glad to say an overhead monorail transfer system may be the answer.

An overhead chain monorail system is the most common type hanging conveyor generally used in a production facility to move parts from one location to another. They take advantage of the generally unused vertical space above the working area. Using curved sections or even with elevators, they bring parts down to the level of operators and back up to higher elevations. Overhead monorail conveyors can pass through production areas that humans can’t like through ovens and robot work cells.

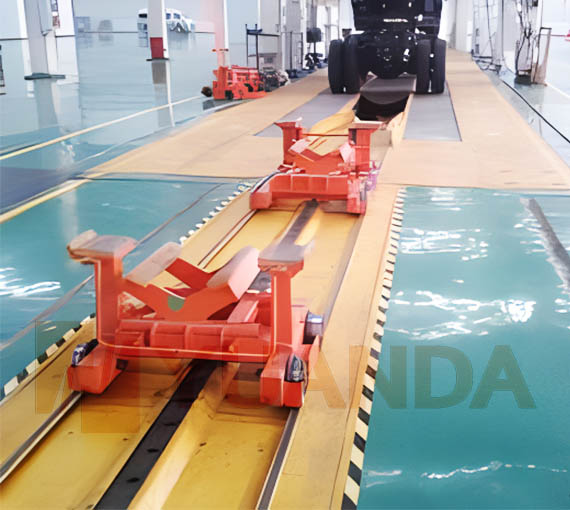

Running on different tracks, the monorail conveyor system can be divided as aluminum tube monorail overhead conveyor, I beam trolley monorail overhead conveyor, enclosed track monorail overhead conveyor and power and free monorail overhead conveyor. With different driving mechanism, there are manual monorail overhead conveyor, motor driven monorail overhead conveyor and friction driven monorail overhead conveyor. Sorted by installation methods, it can be designed as enclosed track overhead monorail conveyor, which is installed on support steel structure or roof ceiling mounted, and inverted floor mounted monorail conveyor, or called inverted monorail system, installed on ground level. Made by different raw material, there can be aluminum alloy monorail overhead conveyor and stainless steel overhead monorail conveyor. With chain or not, it can be made as monorail overhead chain conveyor and chainless monorail overhead conveyor system.

These different types of monorail overhead conveyors are used for finishing system, automotive assembly line, powder coating industry, textile processing and spinning, product transport, process automation, vehicle body shop, manufacture plant, slaughterhouse, workshops, automobile production line and more industries.

Monorail Overhead Conveyor System Components, Accessories and Monorail Overhead Conveyor System Spare Parts

The Overhead Monorail Enclosed Track is a versatile overhead designed to satisfy the requirements of manufacturing and finishing operations where light loads are handled. There are no exposed moving parts, making this overhead conveyor system, exceptional for product finishing and powder coating applications. This configuration avoids corrosion, damage and wear found in traditional systems. The aluminum enclosed track protects product from contamination that typically falls from open chain conveyors. And this monorail enclosed track conveyor also protects the chain from airborne dirt, abrasives and solvents, prolonging chain life. The standard horizontal and vertical curves can make tight changes in direction and elevation, freeing up valuable floor space for other assembly and storage operations. The overhead monorail system also can be upgraded to a power and free system utilizing all existing components.

Other available components and spare parts are: heavy duty universal link conveyor chain, monorail track, spinner, swivel hook, oven expansion joints, automatic chain lubricator, suspension fittings, worm drive unit, tension unit, expansion unit, inspection unit, lubrication unit, Take-up assembly, chain sprocket, pendants, welding jig, etc.

Monorail Overhead Conveyor System Application

The monorail overhead hanging conveyor system offers flexibility and reliability in high temperature resistant working environments. Our motor driven monorail overhead conveyor functions as a versatile storage facility between different production steps, and provides an ideal solution for transporting items through various plant processes, such as domestic appliances, wood furniture, automotive parts, fruits, cartons, sports and leisure goods and garment handling.

The monorail overhead conveyor system is designed for surface treatment industry, automotive industry, food industry, bicycle manufacturers, workshops, logistics and e-commerce industry, intralogistics industry, omnichannel retail, carton delivery system, distribution and sorting, industrial paint lines, foundry and timber factories, finishing and processing systems, assembly operations, parts transfer, textile transfer systems, sorting, storage, transfer and transport, garment handling, displays and entertainment in shopping malls and super market. The monorail overhead conveyor system’s versatility makes itself be indispensable in almost every industry.

Monorail Overhead Conveyor System Manufacturer in China

YUANDA Company is a monorail overhead conveyor system supplier and manufacturer in China. We not only design and supply the conveyor, but also provide the complete software and control systems and monorail overhead conveyor installation service, maintenance and training on a turnkey basis. We have exported to many countries including: Saudi Arabia, Australia, European, United States, Canada, Indonesia, Mexico, Chile, Peru, UAE, Malaysia, Middle East, the United Kingdom, EU, etc. We have many success conveyor projects from companies in the automotive and textile logistics sectors that have successfully implemented our overhead monorail conveyor systems. These companies have recognized the benefits of our modern latest solutions and optimized their logistics processes. By using our industrial overhead conveyor technology, they have been able to increase efficiency of material handling, reduce lead times of work flow, and improve the flexibility of their supply chain. Contact us now to learn more about our conveyor designs and discuss your own needs.

Related Products

Overhead hanging garment conveyors are a premium garment handling, storage, retrieval, transport, delivery, sorting conveyor system. The monorail systems are used for uniform and clothes in laundry, factory, warehouse and production line.

Automated Electrified Monorail System(EMS) is an overhead conveyor system which contain individually motorized carriers that draw energy from an aluminum track mounted bus bar and transport pallet loads throughout automotive assembly line.

Either enclosed track or I beam type, manual overhead conveyor system is a hand push-pull monorail trolley conveyor, used for spray painting, powder coating line, assembly line, carton, garment, surface treatment, automotive industry, and finishing system.

In floor mounted towline conveyor system is an inverted chain conveyor designed to pull carts along a factory ground floor, used in assembly lines, manufacturing plants, surface treatment industry, finishing, spray painting, powder coating and warehouses.