Overhead Conveyor System

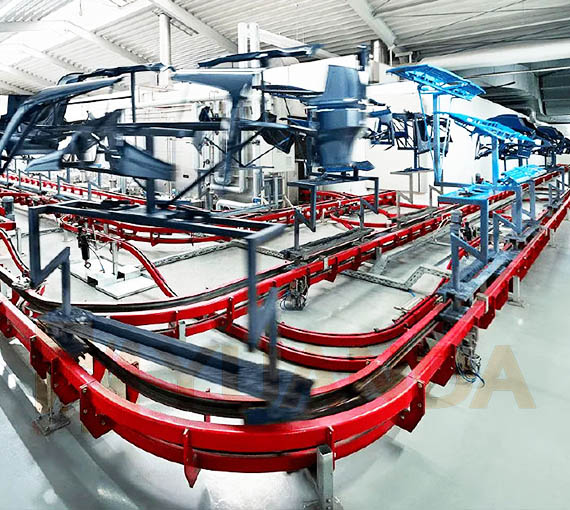

Inverted Power and Free Conveyor

Inverted power and free conveyors are a versatile and efficient type of chain conveyor system that can be used to improve the productivity and efficiency of a wide range of manufacturing and assembly processes.

Chain carrier pitch:300mm 400mm 16”

Max. Load per Trolley: 250kg

Max. Load per Loadbar: 500kg

Models: Inverted P&F Conveyor System

Horizontal bends: 750 mm radius at 15°/ 30°/ 45°/ 60°/ 90°

Vertical bends: 1118 mm radius at 15°/ 30°/ 45°

Drive unit: Caterpillar drive or Worm drive

Switches: Pneumatic / Electric

Speed: Variable speed (custom)

Power supply: AC-3Phase-220/380/400/415/440V-50/60Hz

Inverted Power and Free Conveyor manufacturer: China supplier

Inverted Power and Free Conveyor price: $30,000~$90,000

Inverted Power and Free Conveyor

Design of Inverted Power and Free Conveyor

The Power and Free floor conveyor, which is the most technically complex type, offers asynchronous conveying. Each set of trolleys can stop and start independently and move loads at different speeds.

Power & Free floor conveyors are based on a dual profile system. The upper ‘free’ profile is used for the trolleys and the lower ‘power’ profile is used for the power chain. Pusher dogs are fitted to the power chain at the same pitch and are used to pull the carriers around the system.

Stop stations are used to disengage the link between the power chain and the trolleys. When a stop station is closed, the carrier stops while the power chain continues to move. Due to the design of the pusher and trolley, several carriers can accumulate behind a stop station.

This heavy duty conveyor is a self accumulating Power & Free system, setting a new solution when it comes to handling the largest, and heaviest, unbalanced jigs.

Developed for applications where the need for Power & Free technology is required in sections such as storage areas, ovens etc. where space is at a premium, but where general process areas only require fixed pitch operation. Supreme accuracy in guiding is secured by the 4 horizontal guide bearings as well as the fully adjustable “Free” track. Compared to traditional skid systems or roller conveyors, the Power & Free floor conveyor system operates with high reliability and smoothness. This is due to the limited use of drive units and sensors, requiring a minimum of effort and interference from the control system.

Today, our floor mounted power and free conveyor systems operate in a wide range of demanding industries. Usually supplied with a frequency converter to achieve the desired production speed. Floor mounted Power & Free conveyors are used for assembly lines, paint lines and also in combination with robots.

Features of Inverted Power and Free Conveyor

Name: Reversed mounted power and free conveyor system

Chain carrier pitch: 406.4 mm / 16”

Max. Temperature: 250°C / 446°F

Max. Load per Trolley: 200kg / 441 lbs

Max. Load per Loadbar: 400 kg / 882 lbs

Standard Length, straight profile: 3.0 m / 9.8 ft

Horizontal bends: 750 mm / 29.5” radius at 15°/ 30°/ 45°/ 60°/ 90°

Vertical bends: 1118 mm / 44.0” radius at 15°/ 30°/ 45°

Drive unit: Caterpillar drive / Worm drive

Tension unit: Draw bolt

Switches: Pneumatic / Electric

Two rails, or Hollow section enclosed C rail channel profile track design

Optimum Use of Floor Space

Electric control system with frequency inverter

Types: Light duty inverted power and free conveyor, heavy duty inverted power and free conveyor

Possibility to accumulate in line for the inverted P&F conveyor system

No need for expensive control systems for accumulation sections due to self accumulating design

Operate at different process speeds on the same line

Low maintenance - less moving sensible parts require less attention

Full flexibility – with the same advantages as traditional Power & Free systems (switching gates, accumulation zones etc.)

Simplified plant design - compact profile design minimizes restriction in airflow in spray booths, flash offs and ovens.

Applicable industries: Inverted power and free conveyor for automobile industry, workshops, manufacturing plant, automotive industry, paint finishing and assembly lines, surface treatment industry, energy & mining.

Technical Data & Technical Specifications of Inverted Power and Free Conveyor Systems

Chain carrier pitch: 180mm / 270 mm / 300mm Max. temperature (surrounding): 250° C Max. load per 4-wheeled trolley: 200kg 250kg Max. load per wagon (load bar with two trolleys): 400kg 500kg Standard length, straight profile: 3.000 mm - equipped with flanges Trolley bearings: Closed and greased for low maintenance

| Horizontal curves: Degree: 90° / 45° / 30° / 15° Radius: 600mm 700mm 1000 mm Vertical curves: Degree (depending on work-load): 30° / 15° Radius: 1200mm 1500mm 2500mm Special dimensions on request. Drive unit: Straight double sided version with caterpillar chain drives Tension unit: Manual and pneumatic version

|

Switching gate: Pneumatic blade version (without separate transfer sections). R = 700 mm Accumulation stops: Pneumatic version Lubrication: Pneumatic fog or Pneumatic point lubrication – automatic Accumulation features: In line, 45° and parallel (90°) Special features: Turning stations, drop sections, switching gates, transfer units and chain switches |

*Heavy duty inverted power & free floor conveyor specifications may be subject to change without notice

Applications of Inverted Power and Free Conveyor Systems

Inverted Power & Free Conveyor transports the product on a pedestal, therefore production line operations can be performed quickly and efficiently without obstruction. The power and free inverted chain conveyor system may be mounted on the floor, flush with the floor, or at building truss height to accommodate plant conditions.

In contrast to the Overhead P&F conveyors, the floor based Power & Free system puts the conveyor down at floor level with the part above. This in-floor chain conveyor system can be useful for lighter parts that do not easily lend themselves to be hung from overhead conveyors. This Power & Free Enclosed Track Inverted Conveyor also offers much cleaner environments for painting as there is no conveyor overhead to drop contaminate down on to the parts.

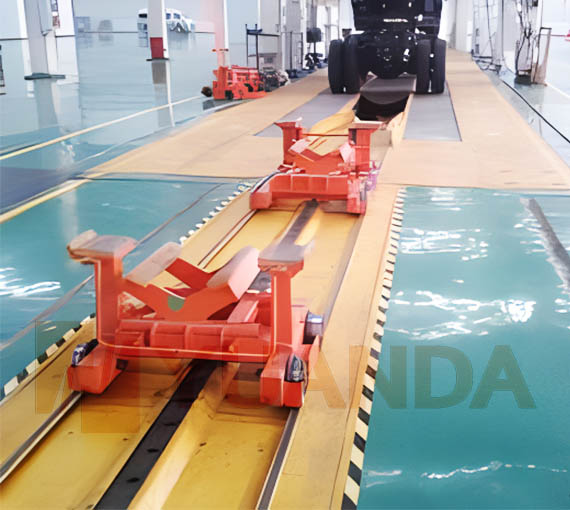

With different structure, the conveyor can be made as inverted power and free chain conveyor system, inverted power and free monorail floor conveyor system, inverted floor mounted power and free conveyor system and friction drive inverted power and free conveyor. For automotive industry workshop, it always designed as towline floor conveyor, which is mounted on the floor towline conveyor system.

The Inverted Power and Free Conveyor Systems are used for production areas or delivery systems that require accumulation such as general assembly lines, manufacturing plants, warehouses, body shop, surface treatment, paint finishing system, powder coating, spray painting and oven drying. They are well-suited for handling a wide variety of products, including automotive parts, appliances, electronics, and food and beverage products. This heavy duty Power & Free floor conveyor can realize multiple functions including: Accumulating, Bias & Trias Banking, Carrier Indexing, Elevation Changes, Production Rate Variation, Segregation, Sort, Start/Stop, Storage, and Transfer.

We have many different models of inverted power and free conveyor for sale, contact us online now for more details.

Inverted Power and Free Conveyor Accessories, Components and Inverted Power and Free Conveyor Spare Parts

The Inverted Power & Free monorail conveyor system, consists of two profiles. In the lower “Power” profile the power chain is driven by one or more drive units. In the upper “Free” profiles the purpose designed trolley and wagon sets are driven by power chain carriers, via pivotal pawls attached to the front and back of the trolley.

The trolley body is made of laser cut and folded plates and is equipped with 4 sealed load carrying wheels and 4 sealed horizontal wheels for side guiding, which runs through floor conveyor track.

Both the power chain carrier pitch and the accumulation distance are designed according to customer specification and requirements.

Each trolley and wagon set can be separated from the power chain and accumulated in line, 45° or 90° zones. When reaching a closed accumulation stop or when reaching the tail of the previous trolley, the accumulation lever is lowered and the trolley pawl units are lifted.

Conveyance with loads in rise and fall sections is possible due to a uniquely designed link between the chain carriers and the trolley pawls.

Other available components and spare parts are universal link chain, drive units, enclosed track, tension, Power & Free trolleys, Power & Free track, Caterpillar drive unit, jigs, tension, Take up, switches, lubrication units, tension units and rotation devices.

Inverted Power and Free Conveyor System Manufacturer in China

Inverted Power & Free Conveyors are the practical material transfer systems to save space while using Power & Free technology. As an inverted power and free conveyor supplier and manufacturer in China, our company provide a vast range of services that includes design, manufacturing, testing, inverted conveyor installation, commissioning and turnkey project administration. We have also exported to many countries including: Saudi Arabia, Australia, European, United States, Canada, Indonesia, Mexico, Chile, Peru, UAE, Malaysia, Middle East, the United Kingdom, EU, etc. Our company provide bespoke inverted conveyor systems to suit your budget. Contact us now for inverted power & free conveyor price.

Related Products

Overhead hanging garment conveyors are a premium garment handling, storage, retrieval, transport, delivery, sorting conveyor system. The monorail systems are used for uniform and clothes in laundry, factory, warehouse and production line.

Automated Electrified Monorail System(EMS) is an overhead conveyor system which contain individually motorized carriers that draw energy from an aluminum track mounted bus bar and transport pallet loads throughout automotive assembly line.

Either enclosed track or I beam type, manual overhead conveyor system is a hand push-pull monorail trolley conveyor, used for spray painting, powder coating line, assembly line, carton, garment, surface treatment, automotive industry, and finishing system.

In floor mounted towline conveyor system is an inverted chain conveyor designed to pull carts along a factory ground floor, used in assembly lines, manufacturing plants, surface treatment industry, finishing, spray painting, powder coating and warehouses.