Overhead Conveyor System

Overhead Power and Free Conveyor System

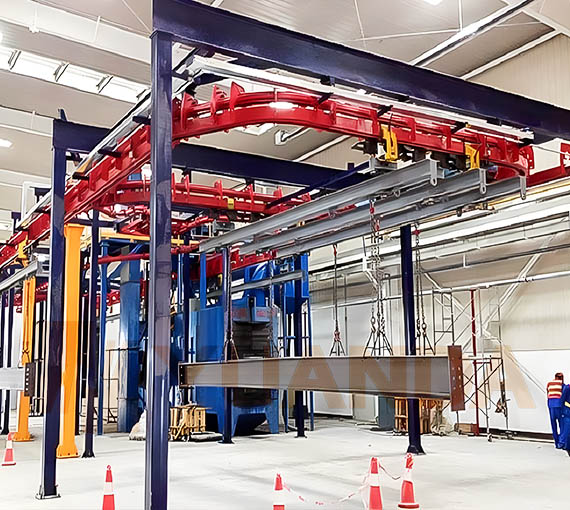

The Power & Free Overhead Conveyor is a chain conveyor system that transports loads along a double-track system. It is a highly flexible system that can convey loads at speeds suited for various processes, including painting, assembly, branching, storage, and final assembly.

Model No.: X348 X458 X678 UN400 UN300

Chain carrier pitch:300mm 400mm 16”

Max. Temperature: 250°C / 446°F

Models: P&F Conveyor

Horizontal bends: 750 mm radius at 15°/ 30°/ 45°/ 60°/ 90°

Vertical bends: 1118 mm radius at 15°/ 30°/ 45°

Drive unit: Caterpillar drive or Worm drive

Switches: Pneumatic / Electric

Speed: Variable speed (custom)

Power supply: AC-3Phase-220/380/400/415/440V-50/60Hz

Power and Free Overhead Conveyor manufacturer: China supplier

Power and Free Overhead Conveyor price: $30,000~$90,000

Overhead Power and Free Conveyor System

Design of Overhead Power and Free Conveyor Line

Overhead Power & Free conveyors are based on a twin-track system. It is designed to handle complex material handling processes. Their unique dual-track system, one powered and one free, allows carriers to move independently, enabling accumulation and stopping without affecting the entire paint line. This versatility ensures that our overhead power and free chain conveyors are suitable for a wide range of applications, from manufacturing operations to paint finishing systems and automated storage solutions.

Our overhead power and free conveyor systems are built to handle heavy loads and can easily navigate inclines, declines, and curves. The enclosed track design protects the chain and bearings from contaminants, ensuring durability and reducing maintenance needs. Carriers may be routed automatically through switches to follow specific process paths or be sorted for proper sequencing. Asynchronous operation by means of varying transport speeds and the ability to stop individual carriers provide maximum line flexibility.

Overhead Power and Free conveyors can handle different speeds and start-stop functions within the same system, which is crucial for processes needing precise control. They support asynchronous movement, letting operators work at varied paces across different sections, enhancing productivity in assembly lines, for example.

Power and Free Conveyors systems provide the unique ability to stop individual loads without stopping the entire production line. ‘Power and Free’ is the name that is applied to an Overhead Chain Conveyor System which has the ability to provide a specialised zone to buffer storage for loads. This would be impossible on a conventional overhead conveyor without stopping the entire system. Power & Free Conveyors are a safer type of conveyor system to have in your factory or warehouse there’s decrease in manual movement resulting in fewer potential injuries.

To increase your production capacity where overhead space is limited, power and free overhead conveyor systems offer a broad range of features, including variable chain speeds, high-speed indexing, adaptability to changes in elevation, side-by-side track configurations to improve product transportation, and can accommodate load capacities up to 20,000 pounds. The applications for power and free overhead conveyors include part storage and production buffers, paint application, final assembly procedures, line-side sequencing, and delivery of sub-components.

Features and Advantages of Overhead Power and Free Conveyor System

Model Number: PF380 PF400 XF400

Chain pitch: 200mm 300mm /12” 14” 15” 16”

Max. Temperature: 250°C

Max. Load per Trolley: 200kg 300kg 400kg 500kg 600kg / 441 lbs

Max. Load per Loadbar: 400kg 800kg 1000kg 1500kg 2000kg

Loading capacity: 100lbs 200lbs 500lbs 1000 1500 2000 2500 pounds

Standard Length, straight profile: 3.0 m / 9.8 ft

Horizontal bends: 300mm 600mm 750mm 800mm / 29.5” radius at 15°/ 30°/ 45°/ 60°/ 90°

Vertical bends: 800mm 1000mm 1200 mm 2000mm / 44.0” radius at 15°/ 30°/ 45°

Drive unit: Caterpillar drive / Worm drive / Friction drive / Motor drive

Tension unit: Draw bolt

Rotary stations, pneumatic and electric

Switches: Pneumatic / Electric

Power and free rail from high-tensile profiled steel sections

Lift/Lower stations

Hanger bars with fancy design, easy and quick installation

I beam construction, or Hollow section enclosed C rail channel profile or Lightweight aluminum enclosed track design, aluminum profile rails, aluminum tube.

Anchored bolts must be set in wet concrete ground

Buffer storage area

Accurate positioning

Control system: Computer or PLC programmable control systems

Possibility to accumulate in line

Operate at different process speeds on the same line

Low maintenance

Full flexibility – with the same advantages as traditional Power & Free systems (switching gates, accumulation zones etc.)

Simplified plant design - compact profile design minimizes restriction in airflow in spray booths, flash offs and ovens.

Applicable industries: Power and free overhead conveyor for powder coating line, spray painting line, automobile industry, workshops, manufacturing plant, automotive industry, paint finishing and assembly lines, surface treatment industry, energy & mining.

Overhead lug channel track, with lug extension

• Compact, bolted track design for easy assembly without welding

• Modular system with highest quality moveable components inside the track, ensuring quality and reliability

• Long lasting and robust machinery with low maintenance

• Fully customized layouts are possible according to the floor space requirements

• Advanced automatic PLC-based control system with touchscreen user interface and remote access

twin-track system, dual track system

High strength alloy castings increase life span

Stainless steel chain pusher dog available

Modular designed conveyor components

Stops are simple, compact and to industry standard

g, Carrier Indexing, Elevation Changes, Production Rate Variation, Segregation, Sort, Start/Stop, Storage, and Transfer. Typical applications are paint lines where products must be transported to different process areas and where accumulation is required in e.g. ovens and buffer zones. This type is also highly suited to assembly lines.

Technical Data & Technical Specifications of Overhead Power and Free Conveyor Systems

Chain carrier pitch: 300mm / 400 mm / 600mm Max. temperature (surrounding): 250° C Max. load per trolley: 150kg 200kg 250kg 300kg 1000kg 1500kg Max. load per load bar: 400kg 500kg 1000kg 2000kg 3000kg Standard length, straight profile: 3.000 mm - equipped with flanges Trolley bearings: Closed and greased for low maintenance

| Horizontal curves: Degree: 90° / 45° / 30° / 15° Radius: 600mm 700mm 1000 mm Vertical curves: Degree (depending on work-load): 30° / 15° Radius: 1000mm 1200mm 1500mm 2500mm Special dimensions on request. Drive unit: Caterpillar drive / Worm drive Tension unit: Draw bolt | Switching gate: Pneumatic / Electric Accumulation stops: Pneumatic version Accumulation features: In line, 45° and parallel (90°) Special features: Dual profile system. Turning stations, drop sections, switching gates, transfer units and chain switches. Variable chain speeds High-speed indexing. On-line storage. Adaptability to changes in elevation. |

Types of Power and Free Overhead Conveyor System

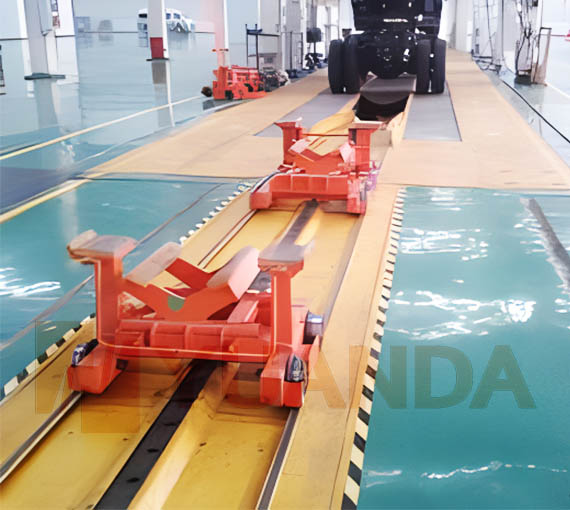

Power and Free overhead hanging conveyors are a special adaptation of traditional monorail conveyors and hand-push free-line conveyors. The basic structure consists of (1) a power line that drives the X-type forged chain, and (2) a free line that supports the trolleys and carriers, which moves via stationary pushers mounted on the X-type chain. These Power & Free overhead track systems can be designed to mount overhead and support a suspended load or can be inverted and floor-mounted to support a live load from beneath, which is known as roof ceiling mounted overhead power and free conveyor and inverted power and free conveyor, or inverted floor power and free conveyor.

With different loading capacity or work duty, the overhead power and free conveyors can be designed as: Light Duty Power & Free Conveyor System that consists of straight and curved tracks. It is used in small, more compact installations, where it is important to still utilize the benefits of a Power & Free type system, such as buffering. Medium Duty Power & Free Conveyor System and Heavy Duty Power & Free Conveyor System is for more heavy-duty applications, and is mainly used in the cast iron, steel and metal product industries, surface finishing and powder coating industry. It has specialized trolleys, pusher dogs and switch and bend configurations especially designed to facilitate heavy loads across the shop floor. These systems are designed to carry products through pretreatment cabins, powder coating booths and drying ovens.

Designed with different structure, there are enclosed track Power & Free overhead conveyor system, Power & Free overhead trolley conveyors and I-beam style (3″, 4″ or 6″) Power & Free overhead conveyor, including X348 Power & Free overhead conveyor, X458 Power & Free overhead conveyor system and X678 Power & Free overhead conveyor.

Equipped with different drive motor, it can be electric motor driven Power & Free overhead conveyors or friction drive Power & Free overhead conveyor system. Made by lightweight aluminum alloy material, it can be aluminum track Power & Free overhead conveyors with aluminum tube, which features clean, clear, quite, low noise, high running speed.

Several sizes of Overhead Power & Free Chain Conveyor are available depending upon your needs. Our company will work with you to develop a system that fits your requirements, whether the overhead power and free conveyor is for powder coating line, spray painting line, product finishing system, sortation, storage, etc. We have the turnkey project management and engineering to ensure your overhead Power & Free conveyor installation is working properly from the very beginning and we will be there to support you going forward.

Power and Free Conveyor Accessories, Components and Power and Free Conveyor Spare Parts

How does a Power and Free Conveyor Work? That is frequently asked by our clients. To increase your understanding of the working principle, here is a list and explanation of the most common parts and composition structure of the overhead power and free conveyor line.

Powder coating line Power & Free conveyors are based on a twin-track system. The rail is divided into an upper profile called the “power track” and a lower profile called the “free track”. The top track is used for the power chain and the bottom free track for the carrier trolleys. The Power & Free rails are bolted together with connecting flanges, allowing for a modular design and easy customizability with other components to form a system.

On an equal pitch, pusher dogs fitted in the power chain are used to pull the carriers around the system. When engaged, the movable cams of the pusher dogs latch onto the trolley to form an interlinked connection.

Stop stations are used to disengage the link between the power chain and trolleys of the two-rail lines(aerial). When a stop station is closed, the carrier will stop while the power chain keeps moving. Because of the pusher dog and trolley design multiple carriers can accumulate behind a stop station, also known as a buffer. When there is a need to hold work-in-process or in temporary storage, carriers can be switched from the main line to recirculating loops or to dedicated spurs for batched storage.

The accumulation system and accumulation stops ensure the carrier trolleys are removed from the roller chain and stored temporarily, which allows them to remain “parked” in a 30°, 45°, 60°, 90° or 120° buffer storage system or even a linear buffer.

Motorized handling circuits including buffers, stop stations, switches, weighing stations, drop sections or hoisting systems, rotating devices, turntables etc. will be equipped with power and free systems. Among all conveyors, overhead P&F systems offer the maximum of possibilities, cumulating technical advantages of the other models. Before all, a power and free system is a motorized conveyor inside which different move speeds and also manual moves may be included.

P&F overhead conveyor system may be seen as the opposite of a manual conveyor able to receive one or more motorized areas!

Work pieces hang on trolleys, load bars or carriers which are driven by a conveyor chain. The chain is regularly fitted with overriding dogs. A power and free installation can receive one or several driving chains having different running speeds.

The self accumulating Power and free overhead conveyor system may also be located at floor level or in a pit. Work pieces are placed onto adapted supports and conveyed by the floor power and free conveyor.

Flow control of the overhead or floor handling system is controlled by the PLC of the conveyor automation. The automatism level for a power and free conveyor will depend of each handling circuit and possible connections with other electrical cabinets. Touchscreens, bar code readers etc. will complete the whole installation. Ranging from simple PLC-based controls to complex PC-based routing and tracking systems, we offer a variety of control systems that can make your material handling work easier.

As a provider of turnkey installations, our company provide the whole control system. Drive and accumulation principle of the power and free conveyors are simple, reliable and tested by numerous installations.

Other available components and spare parts are universal link chain, front trolley, rear trolley, accumulation trolley, drive units, lifting and lowering stations, rotation rails, merges, fixing station for robot loading/placement, chain transfer joint/variable station, enclosed track, anti backup devices, switches and bends, tension, Power & Free Trolleys, Power & Free Track, Caterpillar Drive Unit, jigs, Take up, full automatic lubrication units, tension units and rotation devices.

Overhead Monorail Power and Free Conveyor System Application

A broad range of manufacturing requirements are easily handled by Power & Free monorail overhead conveyor systems. These features allow the P&F conveyors to interface smoothly with automatic work stations, loading and unloading equipment, and a variety of production robots.

Innovative design features, such as high density accumulation and batch movement, conserve valuable floor space. Power & Free conveyors are designed to transport materials and products efficiently through a variety of manufacturing and assembly processes.

We provide custom solutions to clients in a variety of different industries ranging from bicycle manufacturers to foundaries and timber factories. We are able to provide fully customized solutions to meet our clients’ needs.

Automotive Industry

We are specialized in providing solutions of P&F overhead conveyor system for the automotive industry, namely for the production of trucks, wheels, auto parts and other specialized machinery, where products need to be routed to multiple spray booths or where accumulation in a buffer is advantageous.

Surface Treatment

Our overhead P&F conveyor systems are used widely across the surface treatment industry, carrying the product through flash-off zones, spray cabins, powder coating units, washing areas, pretreatment areas, drying and curing ovens.

The Power & Free overhead chain conveyor enables efficient use of floor space by utilizing vertical space, freely configurable layout in both horizontal and vertical directions. It is capable of automated loading and unloading of transported objects, enables loads to proceed to storage from anywhere on the conveyor line. It is also capable of automatic branching and merging to move the carriers in a fixed direction, and prevents damage and collision between transported objects. Moreover, Power & Free enclosed track overhead conveyor allows for easy alteration or expansion of lines. The centralized and distributed control via computer is equipped on the spray painting line power and free conveyor system.

Our company installs and commissions several different types of fully automated Power and Free Conveyor Systems for sale. If you want to buy overhead power and free conveyor system for your finishing system, please contact us now. We can work with you to design a solution that will fit your operational needs.

Overhead Power and Free Conveyor System Manufacturer in China

YUANDA company manufactures various power and free conveyors in both overhead and inverted configurations. P&F Conveyor Systems are designed to handle live loads from 25 lbs. to 40,000 lbs. The P&F monorail systems vary from a light-duty enclosed track design to a heavy-duty ship channel for the free rails.

While much of the power and free system is standardized, each power and free conveyor is engineered for a particular application. We also offer power and free conveyor installation service, testing, commissioning, and other technical support such as training, documentation like user manual, etc. In virtually all instances, overhead power and free conveyor systems are installed on a turnkey basis to assure proper functioning of the design concepts. We are committed to building the most efficient power and free conveyor systems in the industry.

As an overhead power and free conveyor supplier and manufacturer, YUANDA is a company located in China, but also have sales network around the world. We have exported to many countries including: Saudi Arabia, Australia, European, United States, Canada, Indonesia, Mexico, Chile, Peru, UAE, Malaysia, Middle East, the United Kingdom, EU, etc.

Overhead power and free conveyor’s layout and drawings can also be provided by our technical team. Contact us now for overhead power and free conveyor price.

Related Products

Overhead hanging garment conveyors are a premium garment handling, storage, retrieval, transport, delivery, sorting conveyor system. The monorail systems are used for uniform and clothes in laundry, factory, warehouse and production line.

Automated Electrified Monorail System(EMS) is an overhead conveyor system which contain individually motorized carriers that draw energy from an aluminum track mounted bus bar and transport pallet loads throughout automotive assembly line.

Either enclosed track or I beam type, manual overhead conveyor system is a hand push-pull monorail trolley conveyor, used for spray painting, powder coating line, assembly line, carton, garment, surface treatment, automotive industry, and finishing system.

In floor mounted towline conveyor system is an inverted chain conveyor designed to pull carts along a factory ground floor, used in assembly lines, manufacturing plants, surface treatment industry, finishing, spray painting, powder coating and warehouses.