Pedestal Rock Breaker Boom System

Rock Breaker Boom Stationary Hydraulic Manipulator Arm

This mechanical boom manipulator with hydraulic hammer is specially designed for crushing rocks in mining and stone crusher plant to clear blockages.

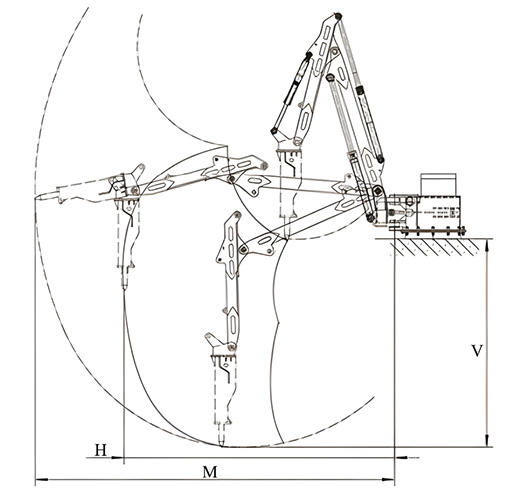

Horizontal Reach: 3~18m

Vertical Reach: 2.5~16m

Hammer Mass Weight: 250kg~4000kg

Lifting capacity at maximum reach: 1 2 3 Ton(tonne)

Models: YZH WHB

Power supply: 380v 50Hz 3Phase

Control method: joystick control, wireless remote control, operator cab control

Fixed rock breaker boom supplier: China manufacturer

Pedestal Rock Breaker Boom System Price: $25,000~$55,000

Rock Breaker Boom Stationary Hydraulic Manipulator Arm

Pedestal Rock Breaker Boom System Hydraulic Manipulator Design

A hydraulic boom rockbreaker is a machine designed to manipulate large rocks, reducing large rocks into smaller rocks. They are typically used in the mining industry to remove oversize rocks that are too large to be reduced in size by a crusher. Hydraulic pedestal rockbreaker boom system consist of two major components, a hydraulic hammer (used to break rocks) and a boom (the arm). The boom design is robust, using oversize pins and bushings at all joints. A centralized lubrication system maintains a steady flow of grease to each rotating joint. Power is provided by a hydraulic power pack and most installations have remote controls running to an operator’s booth. The motion of the pedestal rockbreaking boom system is driven by hydraulic cylinders with the exception of the swing motion that uses a double ended cylinder driving a large rack and pinion.

There are two major types of manipulator boom rock breakers, mobile and stationary - typically placed on a pedestal or slew frame. Pedestal mounted hydraulic boom systems are typically installed above crusher inlets or hoppers and grizzly screens to minimize downtime and avoid damage caused by oversize product blocking chutes or crusher inlets. A correctly sized hydraulic rockbreaker hammer and suitably positioned pedestal boom system is a well-recognized, safe and reliable solution which can maximize the productivity of any crushing circuit.

Hydraulic Stationary Manipulator Arm Rockbreaker Boom Features

Model No./Series: B300 C350 C450 C500 C600 D300 M630 M550 XL940 XL1400 XL1200 XM750 XM600 XM500 XR600

Input power: 18 30kw 35 40 45 50 55kw

Hydraulic power: 25 40 50 75 100 125 Horsepower

Operating weight: 5000kg 6000kg 7000kg

Maximum boom reach: 3m 3.5m 4m 5m 6m 7m 8m 9m 10m 11m 12m 13m 15m

Horizontal reach: 20 24 28 30 32 34 35 36 38 40 42 45 ft/feet

Vertical reach: 16 18 19 20 21 22 24 25 27 28 ft/feet

Lifting capacity at maximum reach: 1000 2000 2500 3000 4000 5000 lbs (pound) kgs

Swing rotation angle: 170° 180° 330° 360°

No. of jib arm: 2

Rock hammer rod tool diameter: 68mm 70mm 75mm 80mm 85mm 100mm 125mm 135mm 140mm 150mm 155mm 165mm 175mm

Ambient temperature: -25~45℃

Modular design, light weight

Heavy-duty cylinders

Heat treated conical pins

Operating manual controls, Joystick control & 5G automation remote control system(optical fiber cable)

Compatible with heavy duty rockbreakers

Stationary rock breaking manipulator arm pedestal boom system features large pedestal base with large diameter king-pins and swing post

Stationary Manipulator with A Hydraulic Breaker

Stationary Hydraulic Manipulator Arm with Hydraulic Hammer for Breaking Oversize Rocks

Static Type Manipulator with Hydraulic Rock Breaking Hammer

Rock Breaker Booms Manipulator Arm for Sale

Hydraulic Manipulator Arm Rockbreaker

Underground Hydraulic Stationary Manipulator Arm Rockbreaking Boom

Bucket type Hydraulic Stationary Manipulator Mechanical Arm

Technical Parameter of Hydraulic Stationary Manipulator Arm Rock Breaker Boom

RANGE OF MOTION

Pedestal boom rock breaker manipulator’s specifications and custom options available to meet customer specifications and local construction conditions.

Hydraulic Pedestal Rock Breaker Boom System Specifications

Name | Hydraulic Stationary Manipulator Arm Rockbreaking Boom System |

Boom weight | 4000kg~8000kg |

Input power | 30kW 36kw |

Maximum reach | 3m~19m |

Nominal horizontal reach (H) | 3.5m~18m |

Nominal vertical reach (V) | 2m~16m |

Excavation depth | 3m~15m |

Number of joints | 2 or 3 |

Swing rotation | 170° 180° 360° |

Base dimensions | 0.93 x 0.8m |

Hydraulic breaker tool diameter | 3" 4" 5" 6" 7" 8" |

Impact rate for rock breaker hydraulic hammer | 200bpm~800bpm |

Application | Jaw Crusher Blockages Blockages and build-ups Underground mining |

Different Types Of Hydraulic Stationary Manipulator Arm Rock Breaking Boom

As a fixed rock breaker boom systems supplier in China, our comprehensive range of hydraulic manipulator rock breaker boom system enhances the safety, productivity and profitability of crushing operations in mines, quarries and construction sites around the world. The rock breaking equipment comprises many different models, with reaches from 3 meter up to 18 meters. YUANDA delivers complete rock breaking manipulator booms system packages to meet your specific needs.

Light Duty Small Rock Breaker Boom System

Our multi-purpose small range rock breaker booms are lightweight. They are typically used in quarries, next to primary crushers, to clear any blockages and bridging in stationary crushing plants as well as mobile crushers. Depending on the application, Small pedestal boom rock breaker can be operated directly by the valve joystick levers or remotely by radio remote control.

Lightweight small range boom system rock breakers also offer an effective solution for specialized applications such as breaking refractory linings in metallurgical plants.

Mobile Rock Breaker Boom System

These compact multi-purpose boom systems are typically used on portable crushing plants and are fitted directly on the mobile crusher’s structure. These fixed mechanical arm rock breaker manipulators increase productivity significantly by removing bridged rock and breaking oversize in the hopper without the need to stop a plant or reposition equipment. Featuring a low-profile design and light weight, these heavy duty, small size rock breaker boom systems are stable and easy to install as they travel within transport dimensions.

Heavy Duty Static Rock Breaker Boom Systems

The heavy-duty rockbreaker boom has been designed for extreme grizzly applications. Its shock absorbing pedestal mounting reduces vibration in rotating base and foundation and boom swing with slew ring enables wider coverage, easier service access and constant swing torque.

The hydraulic manipulator rockbreaker boom systems can be operated directly by the valve levers or a radio remote control. It can be upgraded with our new Teleoperation Control System, an automation system enabling remote operation via the plant internet network in order to achieve the PLC programmable automated movements such as rotation or breaking.

Stationary hydraulic manipulator arm rock breaker boom system features a multi-fit pedestal that makes replacing the existing and worn-out boom system quick and trouble-free. With a modular design and heavy-duty cylinders, the hydraulic manipulator arm rock breaker is a convenient and safe choice for mining applications.

If you are unsure about which model of the hydraulic manipulator arm rockbreaker boom suit your need, please contact us now. Our specialists will help you choose the right stationary rockbreaker boom, controls and hydraulic power pack to suit the application and work with you to optimise the installation to ensure reliable operation and maximum productivity.

Applications of Rock Breaker System

Stationary rockbreaking manipulators are offered in both stationary and mobile versions. They significantly increase safety of operating the first grade crushers and reduce downtime caused by blocking the crusher with oversized rock materials. Stationary manipulators with booms for crushing oversize allow attaching hydraulic rock breaker hammer of all brands between 1000kg and 4000kg of weight. Machines or hydraulic stationary manipulator for rock breaking can be equipped with manual or remote steering.

We offer a hydraulic manipulator with a hammer for breaking oversize rocks. It is most often used to break up and crush large rock blocks that do not fit in crushers. The stationary manipulator with hydraulic hammer is a separate device mounted anywhere – usually on a stationary crusher. Boom length and range are adjusted to the client’s requirements.

Stationary Rockbreaking Boom Manipulator Parts & Accessories

All hydraulic manipulator arm rockbreaker boom systems include positioning pedestal boom, YUANDA series hydraulic impact breaker, electric/hydraulic power unit, operator controls, first use startup and commissioning including operator and maintenance training.

Heavy-Duty Cylinders

Heavy duty hydraulic cylinders are of welded construction with spherical bearings at both ends. The boom and dipper stick cylinders include cushioning and load drop counter balance valves.

Auto Lubrication System

Auto greasing systems are frequently specified. They include the breaker and all boom lubrication points.

Hydraulic Power Units

Our proprietary designed hydraulic power units position the tank above the pump for a smaller footprint and flooded inlet. The power rating of the electric motor is determined by the selection of the breaker and its hydraulic requirements.

Advanced Remote Controls & Automation System

As standard, all hydraulic manipulator arm rock breaker boom is fitted with remote controls and electro-hydraulic joystick lever controls for safe and effective operation.

With the right choice of modern components, the stationary hydraulic manipulator arm rockbreaker boom system can be integrated with your mining plant automation system. With camera & display monitors, it can monitor your primary from an extra long distance by using strategically placed CCTV and HMI. Tele remote allows the operation of multiple booms up to 15 km with HD quality picture and sound feedback. Select and adjust your views remotely. Transmit your control and alarm signals via optical fiber cable. Adapt our system to the internet or your 4G/5G WIFI network.

Hydraulic Hammer

We offer a full range of hydraulic hammers which complement our stationary rock breaker manipulator boom systems. The power to weight ratio of our range of breakers provides superior efficiency and performance for rockbreaking application.

China YUANDA provides a safe turn-key package comprising hammer, boom, power pack and full electrification of the system. All elements are manufactured to stringent quality and safety standards and are fully CE-compliant.

Installation, Commissioning and Maintenance of Stationary Rock Breaker Booms Manipulator

YUANDA total commitment to the customer encompasses all aspects of product development, design, manufacture, supply, sale and after sales service. Whether you are looking to install or commission a single rock breaking machine or multiple pieces of underground mining equipment, our technicians are here to support you at every step of the process. From feasibility and project management to stationary pedestal mounted rock breaker boom system configuration and training, we can handle the installation and commissioning of equipment from start to finish. Our after-sales service team can be dispatched to the job site to assist with fixed static rockbreaker boom system installation, commissioning, maintenance and training. We offer our customers a complete design to installation service anywhere in the world.

Stationary Rockbreaker Boom Manipulator Supplier/Manufacturer in China

YUANDA knows that stationary rockbreaker manipulator boom systems consist of the stable booms as well as the reliable hammers the industry has to offer. YUANDA always produce with high standard for performance and reliability and has consistently been the choice of professionals in search of the stationary hydraulic rockbreaking solution in mining industy. Based on years of experience, we can customize the proper boom/hammer configuration for your specific purpose. We have exported many static type manipulators with hydraulic rock breaking hammer to many countries, such as United States, Canada, Netherlands, Poland, Indonesia, Mexico, Chile, Peru, UAE, Middle East, the United Kingdom and EU. All our hydraulic manipulator breakers are CE certified. Talk to our professionals online to have more information.

Related Products

Stationary Pedestal Rock Breaker Boom Systems, also known as Hydraulic Rockbreaker Boom Systems, are rock breaking equipment mounted at primary jaw, impact and gyratory crushers, stationary grizzly, mobile and portable crushers for quarry/mining rockbreaking application. Contact China supplier for price now.

China fixed type pedestal rock breaker boom system or rockbreaker boom system is a static, pedestal-mounted, hydraulic powered rockbreaking equipment mounted over the grizzly, primary jaw, impact, gyratory crushers, mobile and portable crushers for oversized rock breaking in quarry and mining plant.

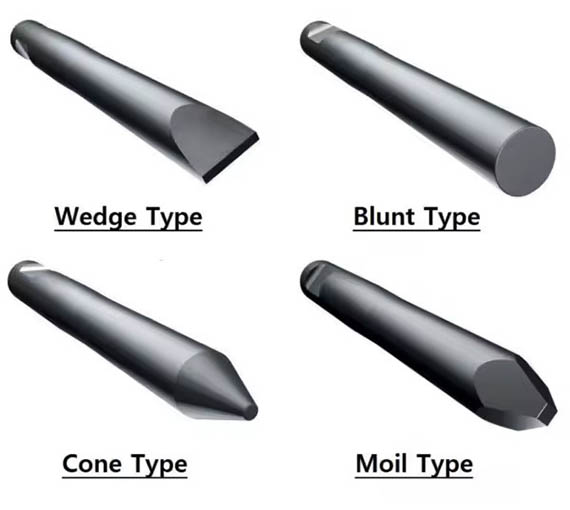

We supply hydraulic rock breaker tools for hydraulic hammers (hydraulic rock breakers) and heavy demolition tool bits. Sorted as breaker chisel, blunt, moil point, and cone type, the working tool is a key attachment, accessory and spare part fitting in a pedestal rock breaker boom system, which is used for rockbreaking, crushing at mine and quarry industry.